A slip-type downhole choke that is easy to salvage

A slip-type well and restrictor technology, which is applied in the direction of mining fluid, wellbore/well components, wellbore/well valve devices, etc., can solve the problem of large lifting friction resistance, low fishing success rate, sealing rubber tube Unable to retract and other problems, to achieve the effect of easy unlocking and improving the success rate of salvage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

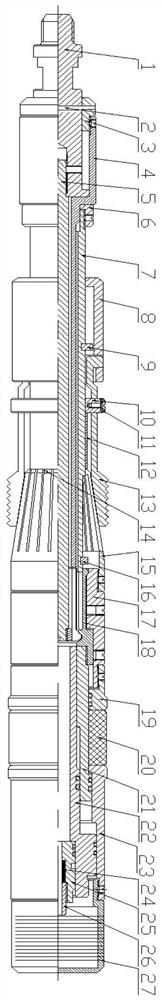

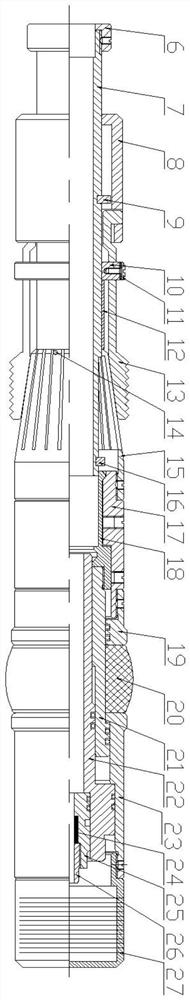

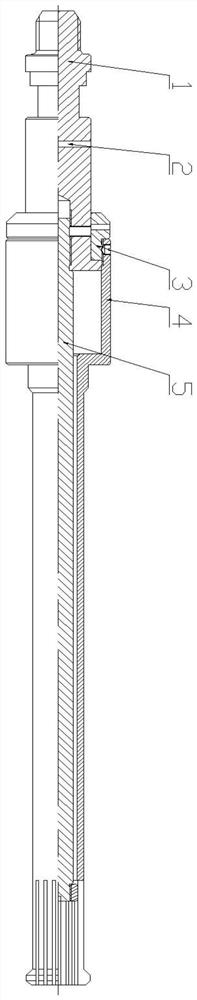

[0025]One easy-saving kadwa-type downhillizer, including launching tools and throttle, lifting the throttle under the putter, the launching tool includes at least the castle 1, the first shear nut 2, the lock cap 3, the shrink claw 4 and The first core rod 5, the inside of the contraction claw 4 is sequentially connected to the cast head 1 and the first core rod 5, and the lock cap 3 is connected to the outer end of the shrink claw 4, and the sprout 1 is connected by the first shear 2. Locking cap 3; the throttle includes at least the salvagep 6, the mandrel 7, the mounar pendulum 8, the first block 9, the positioning ring 10, the ferrule 11, the ferric 13, the second shear nail 14, cone 15 , The second ring 16, the connection section 17, the universal claw 18, the support body 19, the rubber 20, the core 21, the second slew rod 22, the cylinder segment 23, the nozzle 24, the mouth of the mouth 25, the clip 26 And the sand cover 27, the core shaft 7 is connected in the sidewelle 6, ...

Embodiment 2

[0027]Such asFigure 1-4As shown, a kind of easy-saving kadwa-type downhillizer, including launching tools and throttles, connecting the throttle under the putter, the launching tool includes at least the castle 1, the first shear 2, the lock cap 3, shrink The claws 4 and the first core rod 5, the inside of the shrinking claw 4 is sequentially connected to the cast head 1 and the first core rod 5, and the lock cap 3 is connected to the upper end of the shrink claw 4, and the cast head 1 is passed through the first shear. Nail 2 connection lock cap 3; the throttle includes at least the salvage 6, the mandrel 7, the mounted pendulum 8, the first block 9, the positioning ring 10, the ferrule 11, the ferric 13, the second shear nail 14, The cone 15, the second ring 16, the connection section 17, the universal claw 18, the support body 19, the rubber 20, the core 21, the second core rod 22, the cylinder segment 23, the nozzle 24, the nozzle seat 25, Effect 26 and the sand cover 27, the co...

Embodiment 3

[0030]Such asfigure 1 As shown, on the basis of Example 2, the throttle further includes a positioning sleeve 12, and the positioning sleeve 12 is attached to the mandrel 7 and the positioning sleeve 12 is located between the positioning ring 10 and the cone 15. The positioning sleeve 12 does not move the positioning ring 10 to avoid the Kava 13 can't be opened.

[0031]The sauce 13 is 3 sheets, and 3 flavors 13 weeks are distributed. Make sure that the TA 13 is fully anchored and fully locked, and the structure is simple.

[0032]The outer side of the mandrel 7 is a step. The steps of the step shaft 7 have the step of steps, so that when the paws of the cone 15 lose the support, the contraction is realized, and the result of shrinkage causes the ferroviation 13, and the support is reached, and the ferrous 13 and the inner wall of the ferric 13 and the tube column are released. Contact and is easy to unlock.

[0033]Such asFigure 5 As shown, the structure of the first stop ring 9 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com