A motor shaft extension sealing structure and motor

A technology of sealing structure and motor shaft, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low protection ability level and poor sealing effect, and achieve the goal of compressing the motor cost, thin sealing performance, and high sealing protection level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

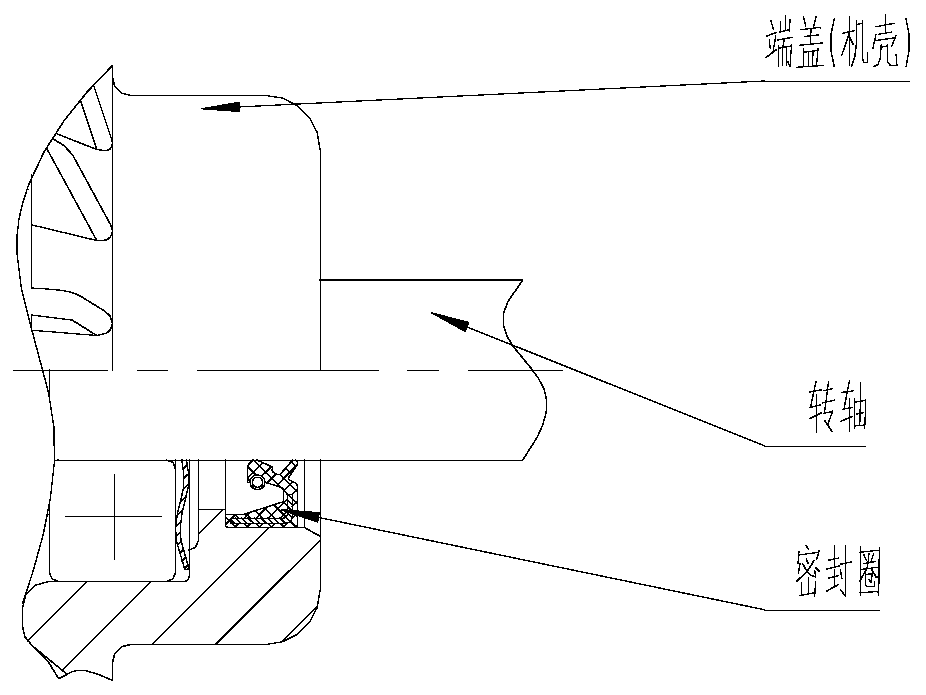

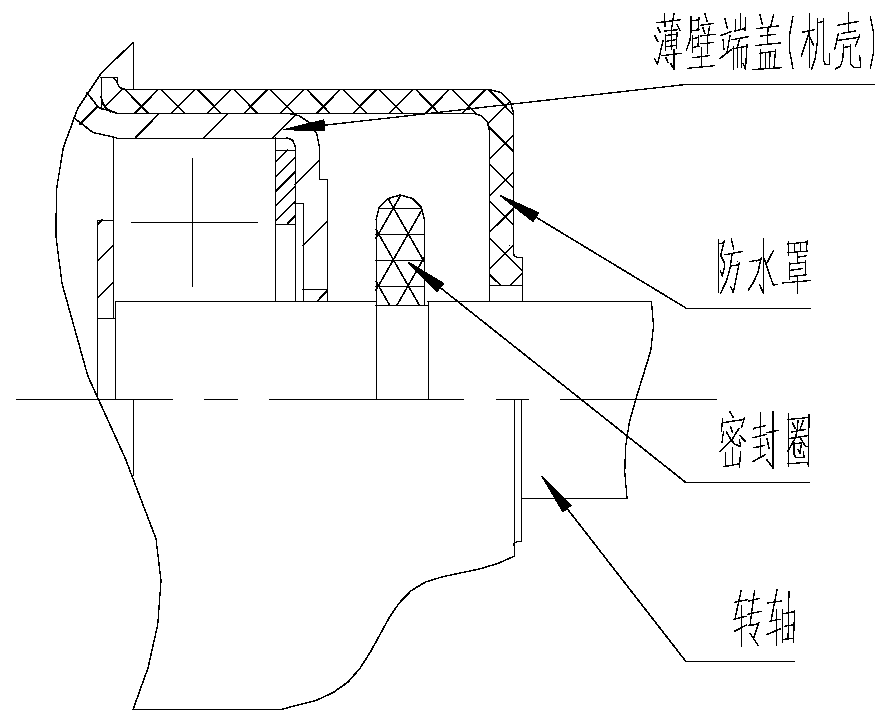

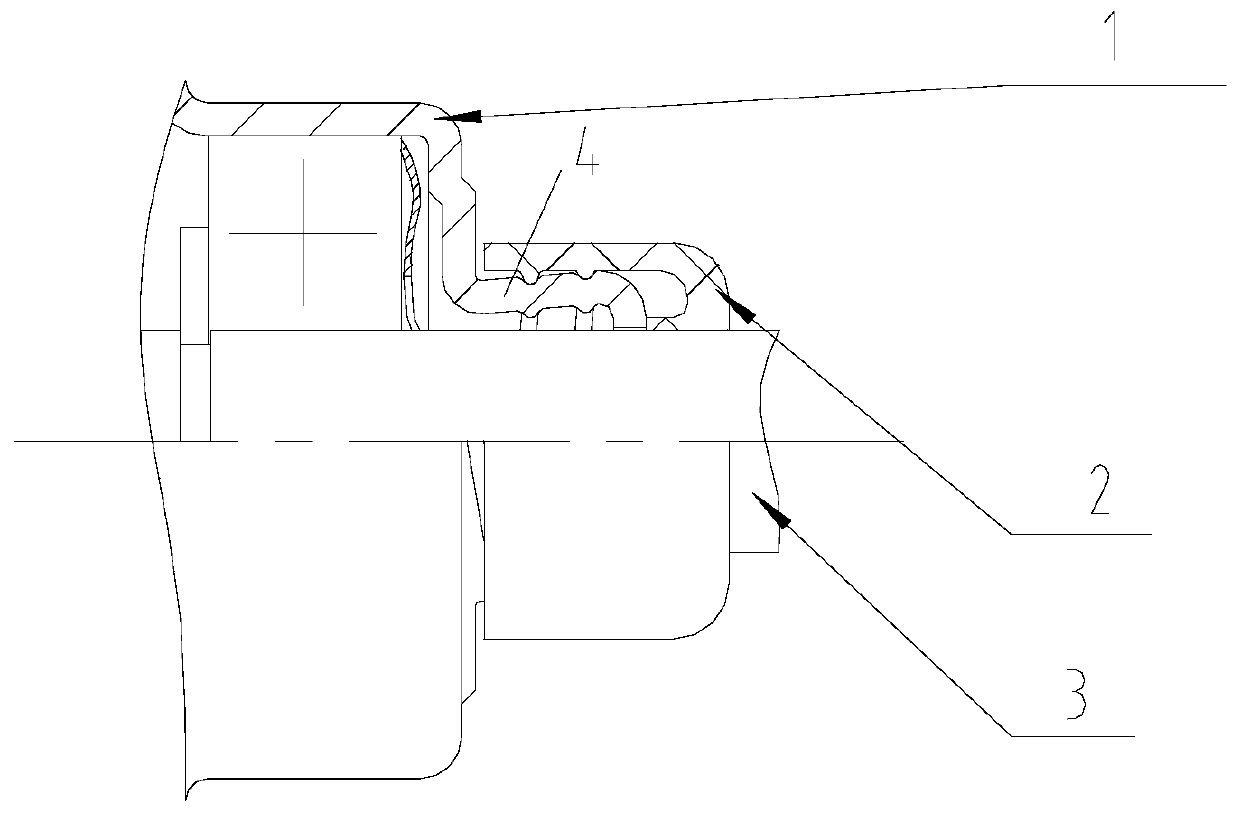

[0050] Such as Figure 3-5 As shown, the present invention provides a motor shaft extension sealing structure, which includes:

[0051] Including end cover 1, sealing ring 2 and rotating shaft 3;

[0052] The end cap 1 has a protrusion 4 at its axial end;

[0053] One axial end of the sealing ring 2 is sleeved on the rotating shaft 3, the other end extends toward the protruding portion 4, and is sleeved on the outer periphery of the protruding portion 4; and the sealing ring 2 can be The rotating shaft 3 is driven to rotate together, and there is relative rotation between the sealing ring 2 and the protruding portion 4 .

[0054]In the present invention, a sealing ring is provided, one end is sleeved on the rotating shaft, and can rotate integrally with the rotating shaft, and the other end is sleeved on the protruding part of the end cover, and there is relative rotation with the protruding part, so that the sealing ring can It forms a static seal with the rotating shaft a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com