Acoustic membrane

An acoustic and acoustic device technology, applied in the direction of diaphragm structure, flat diaphragm, polymer material diaphragm, etc., can solve problems such as material failure, and achieve the effect of low Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] example

[0047] Preparation of membranes according to the invention

[0048] As noted above, all materials may be thermoformable, therefore, in some embodiments of multilayer films according to the present invention, each layer may be produced by extrusion. The inventors have found that films according to the invention can be produced by coextrusion. A method for producing membranes according to the invention is described in WO 2015 / 052316.

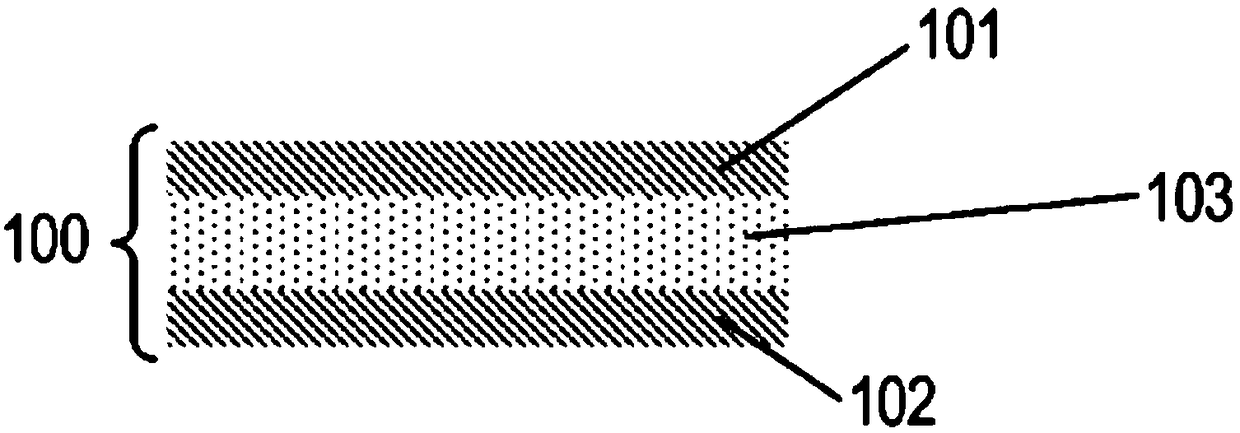

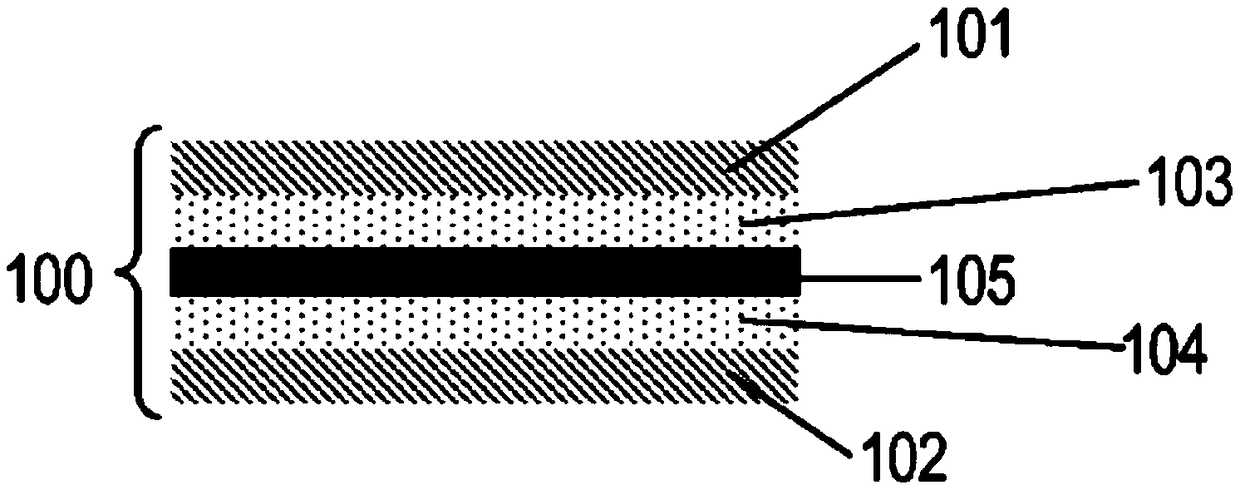

[0049] Three-layer film layout

[0050] figure 1 A schematic diagram of a three-layer laminate of a film 100 having three layers 101 , 102 and 103 according to the invention is shown. The upper outer layer 101 and the lower outer layer 102 are formed of thermoplastic elastomer. The middle layer is the damping layer 103 . Preferably, the outer layers 101 and 102 are formed of the same material, and the upper and lower sides of the membrane 100 are identical to each other. In one embodiment, the outer layers 101 and 102 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com