Camera, camera shooting device and drone

A camera and mounting hole technology, applied in image communication, television, cooling/ventilation/heating transformation, etc., can solve the problems of high space requirements, high cost, complex structure, etc., and achieve small space requirements, low cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

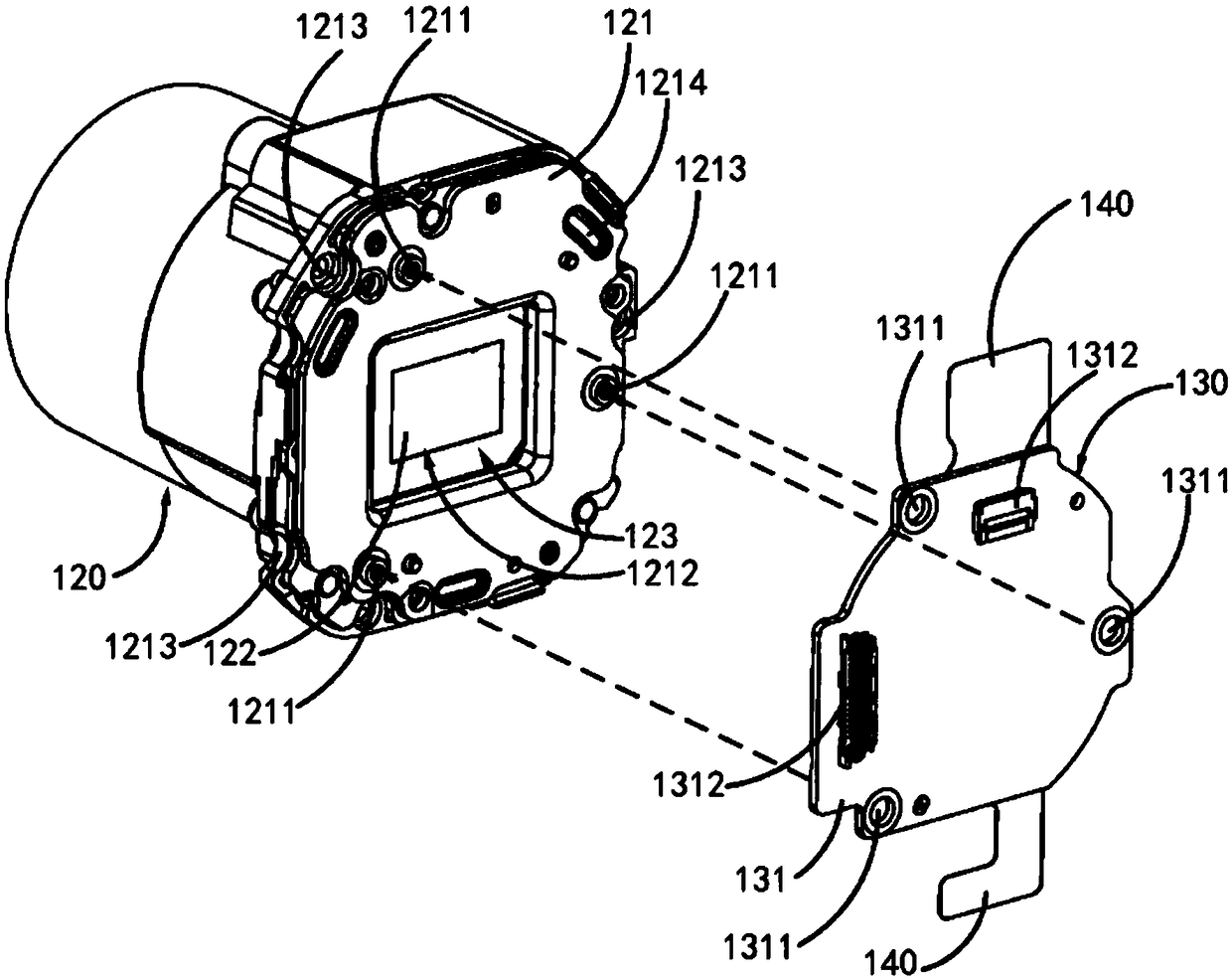

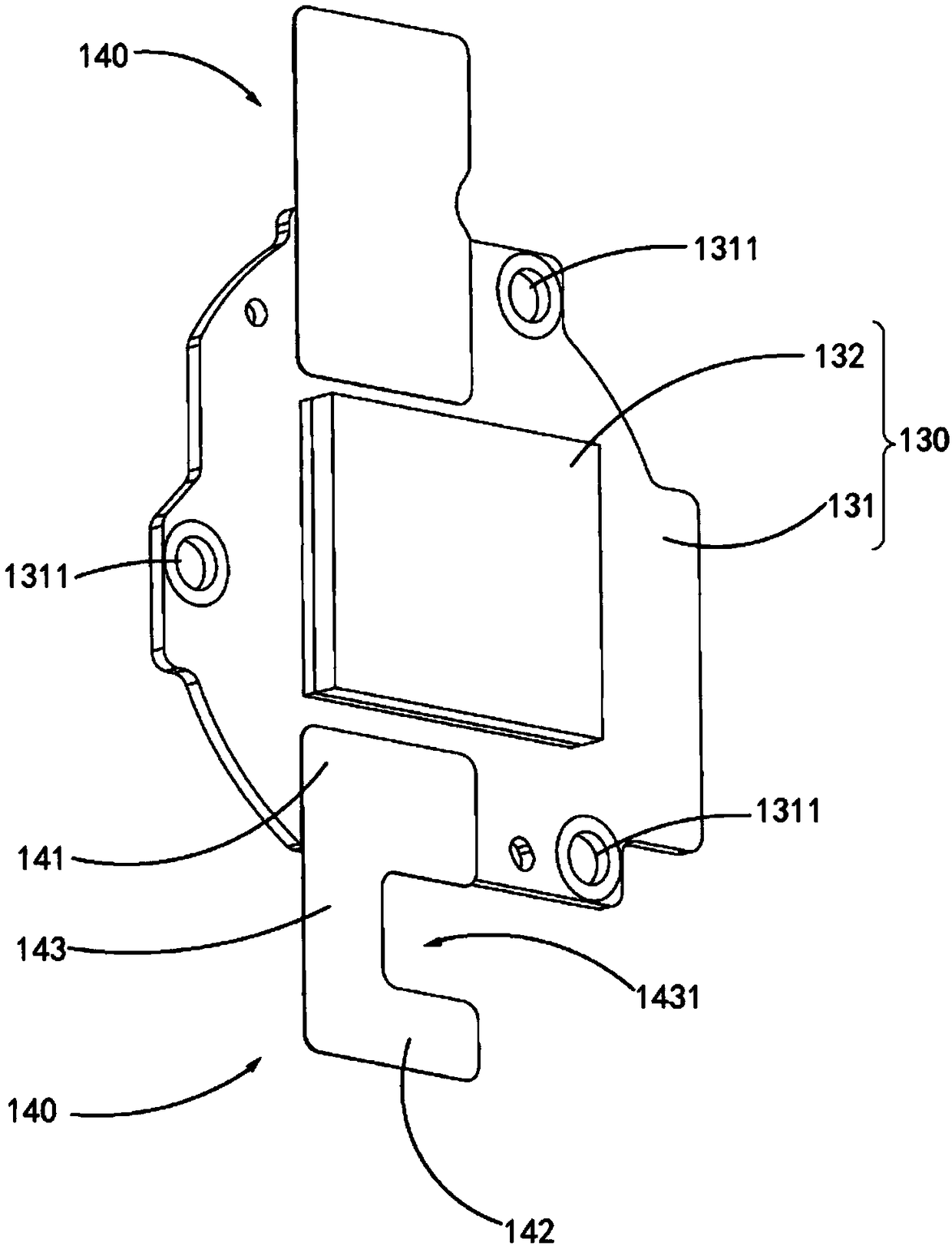

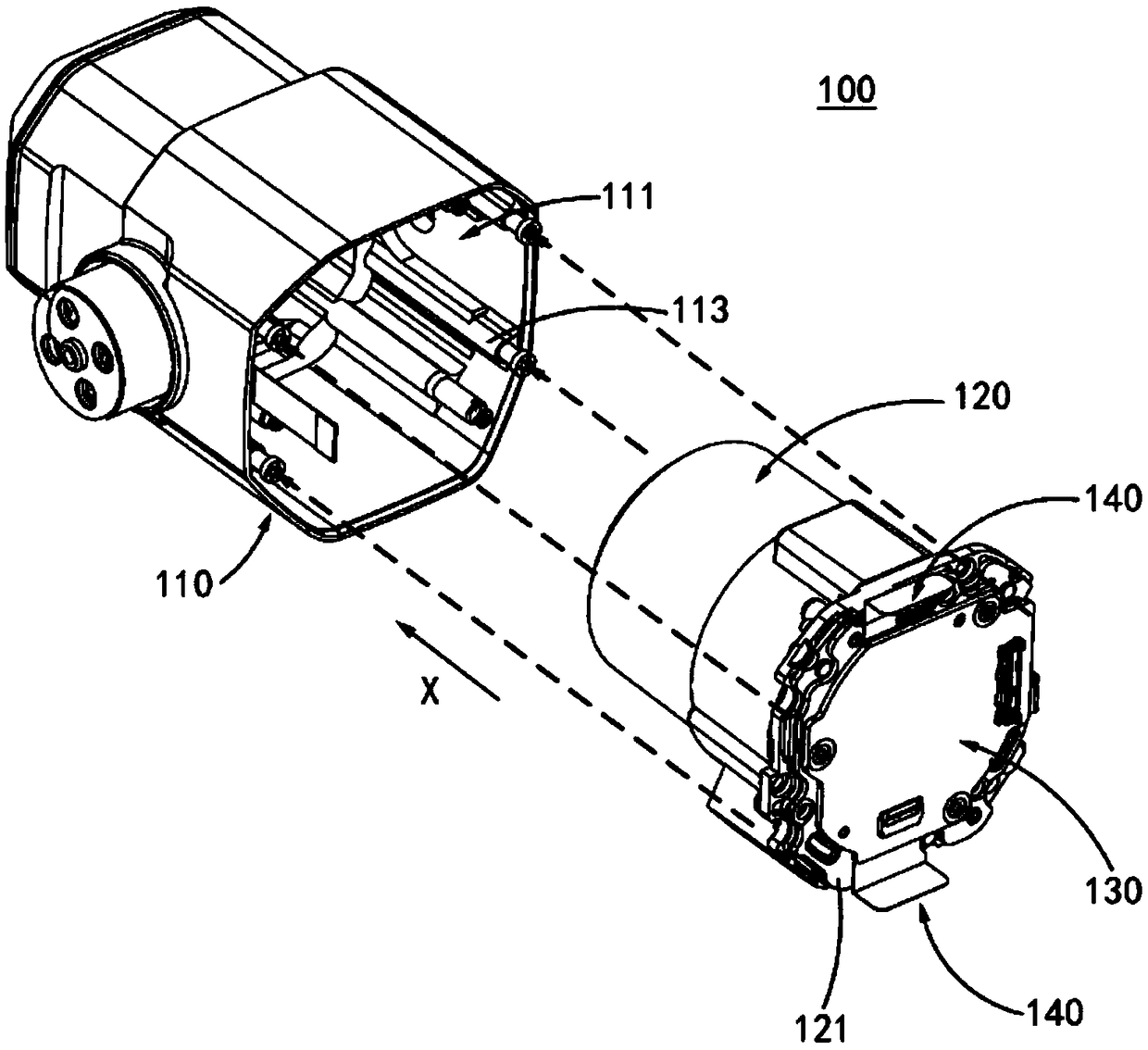

[0058] refer to figure 1 , figure 1 Fig. 1 shows a representative schematic diagram of a partial structure of a camera capable of embodying the principle of the present invention, and specifically shows a schematic diagram of an assembly of a lens assembly and a sensor module of the camera. In this exemplary embodiment, the camera proposed by the present invention is applied to a camera device with a pan-tilt or an unmanned aerial vehicle with a pan-tilt axis as an example for illustration. Those skilled in the art can easily understand that, in order to apply the relevant design of the camera to other types of camera devices or drones, various modifications, additions, substitutions, deletions or other modifications are made to the following specific embodiments variations, which are still within the scope of the principles of the camera proposed by the present invention.

[0059] Such as figure 1 shown, and refer to figure 2 with image 3 , in this embodiment, the came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com