Environment-friendly waste gas treatment device

An exhaust gas treatment device and an environmentally friendly technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve problems such as troublesome maintenance and replacement, time-consuming and labor-intensive delays, and delays in the normal operation of exhaust gas treatment. It achieves convenient operation and improved The effect of installation stability, automatic and quick installation and locking work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

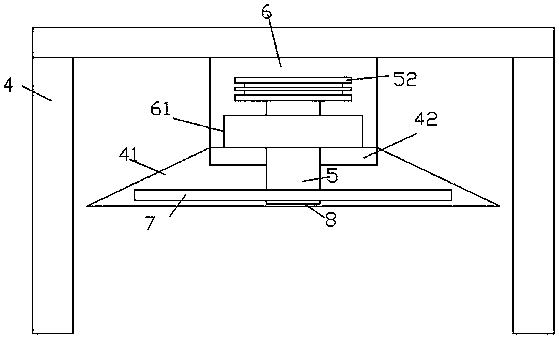

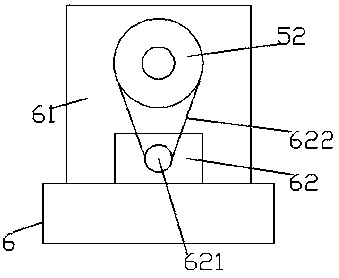

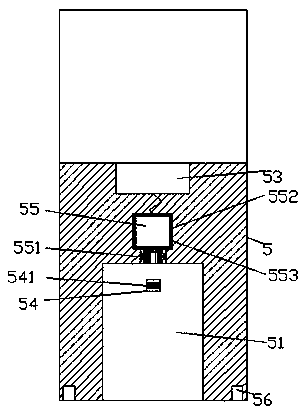

[0027] Such as Figure 1-Figure 9 As shown, an environmentally friendly exhaust gas treatment device of the present invention includes a frame body 4 and a cavity 6 arranged on the upper bottom surface of the frame body 4, a gas collection cover 41 is arranged below the cavity 6, and the gas collection A processor 42 is arranged on the inner top surface of the cover 41, and a square column 61 is fixedly arranged at the bottom of the cavity 6, and a transfer locking shaft 5 extending forward and backward is connected to the inside of the square column 61. A sliding connection cavity 51 is provided in the elongated tail tip on the front side of the locking shaft 5, and an inner connecting shaft 551 is fitted in the rear side wall of the sliding connecting cavity 51, and the rear end of the internal connecting shaft 551 is connected with the locking drive device. 55 to connect with each other, the transfer lock shaft 5 on the rear side of the lock drive device 55 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com