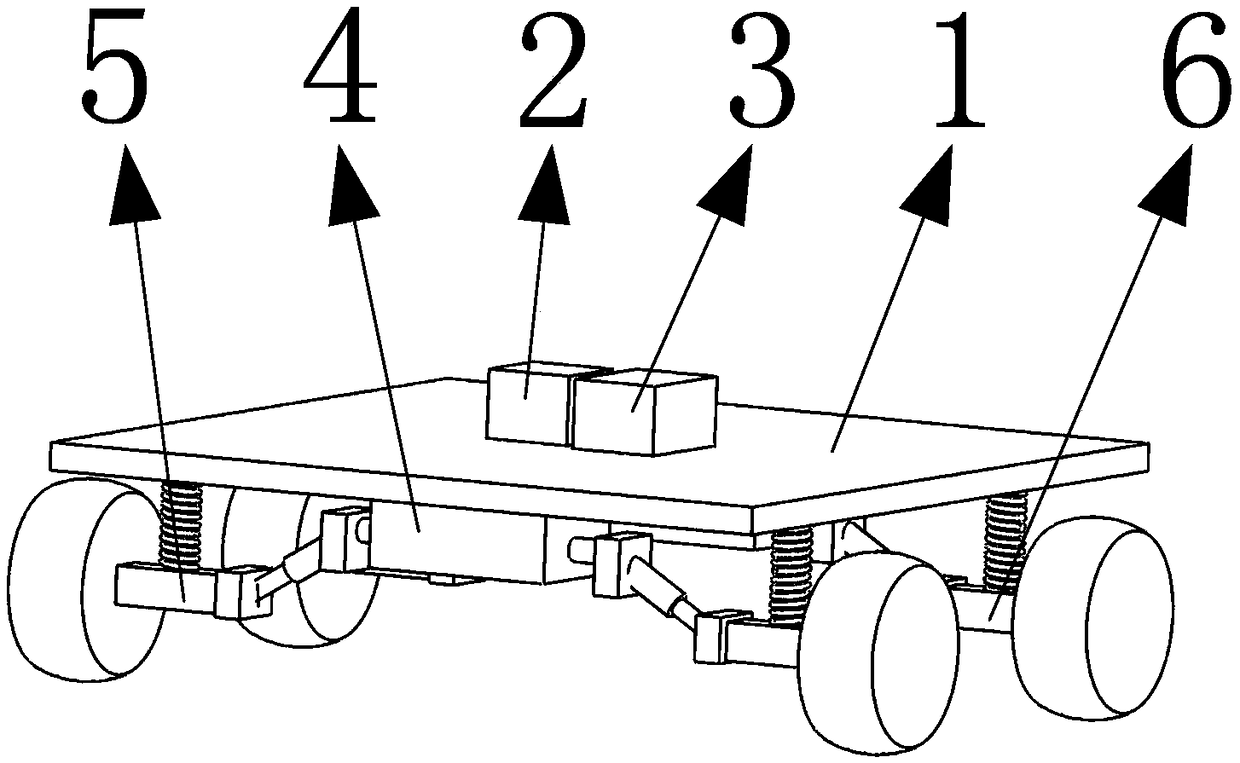

A wheel type four-wheel-drive walking platform for robots

A walking platform and robot technology, applied in the field of robots, can solve the problems of single steering control and the inability of the robot to pass the curve, and achieve the effect of good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

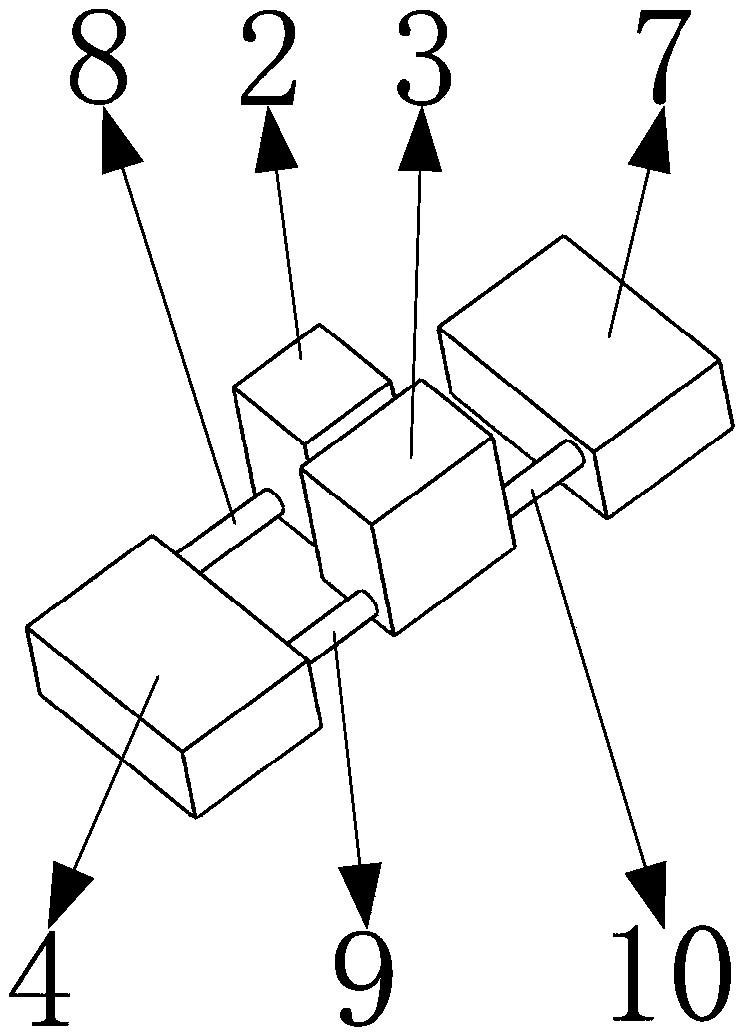

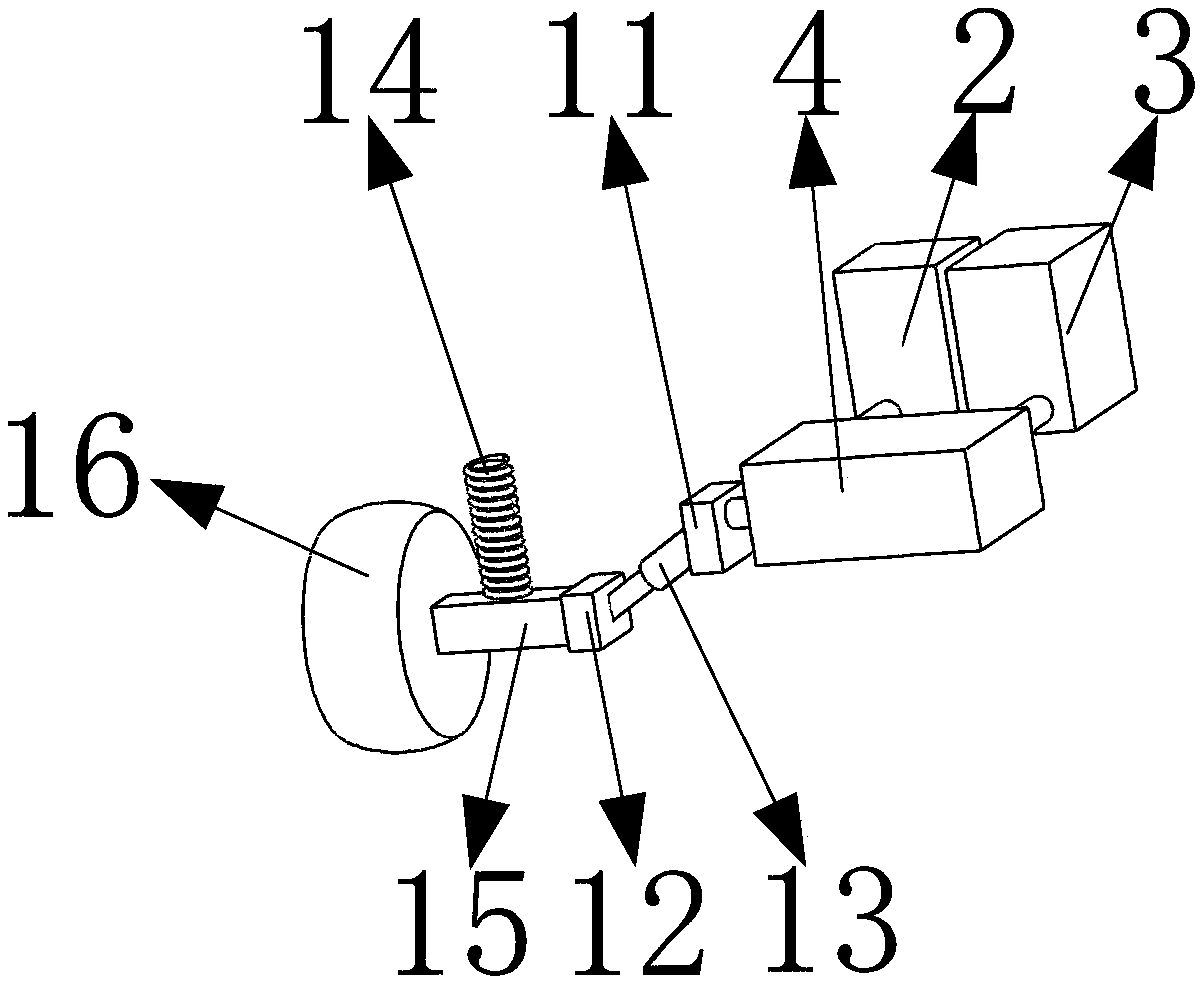

specific Embodiment approach

[0057] The specific embodiment: the input shaft of the robot controls the adjustment motor 2 to rotate; the input shaft on the adjustment motor 2 rotates to drive the adjustment transmission shaft 8 to rotate; the rotation of the adjustment transmission shaft 8 will drive the first bevel gear 34 to rotate; the first bevel gear 34 to rotate It will drive the second bevel gear 35 to rotate; the second bevel gear 35 will drive and will drive the first axle sleeve 36; the first axle sleeve 36 will drive the third bevel gear 38 to rotate; because the fifth bevel gear 40 and the sixth bevel gear 41 are all meshed with the third bevel gear 38, so the rotation of the third bevel gear 38 will drive the fifth bevel gear 40 and the sixth bevel gear 41 to rotate, thereby driving the fourth bevel gear 39 to rotate; the fourth bevel gear The rotation of the gear 39 drives the second shaft sleeve 37 to rotate; the movement of the second shaft sleeve 37 will drive the rotation of the seventh b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com