A method for optimal design of perforation cluster position in staged multi-cluster fracturing of horizontal well

A technique for optimal design, perforation clusters, used in calculations, earthmoving, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is described further below:

[0059] This optimal design method for multi-cluster fracturing perforation cluster positions in horizontal wells:

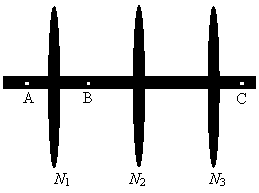

[0060] Step 1. Determine the position of each perforation cluster in the first fracturing stage according to the wellbore characteristics and development requirements.

[0061] Step 2, calculating the induced stress generated by the fracture at the last perforation cluster of the first fracturing stage.

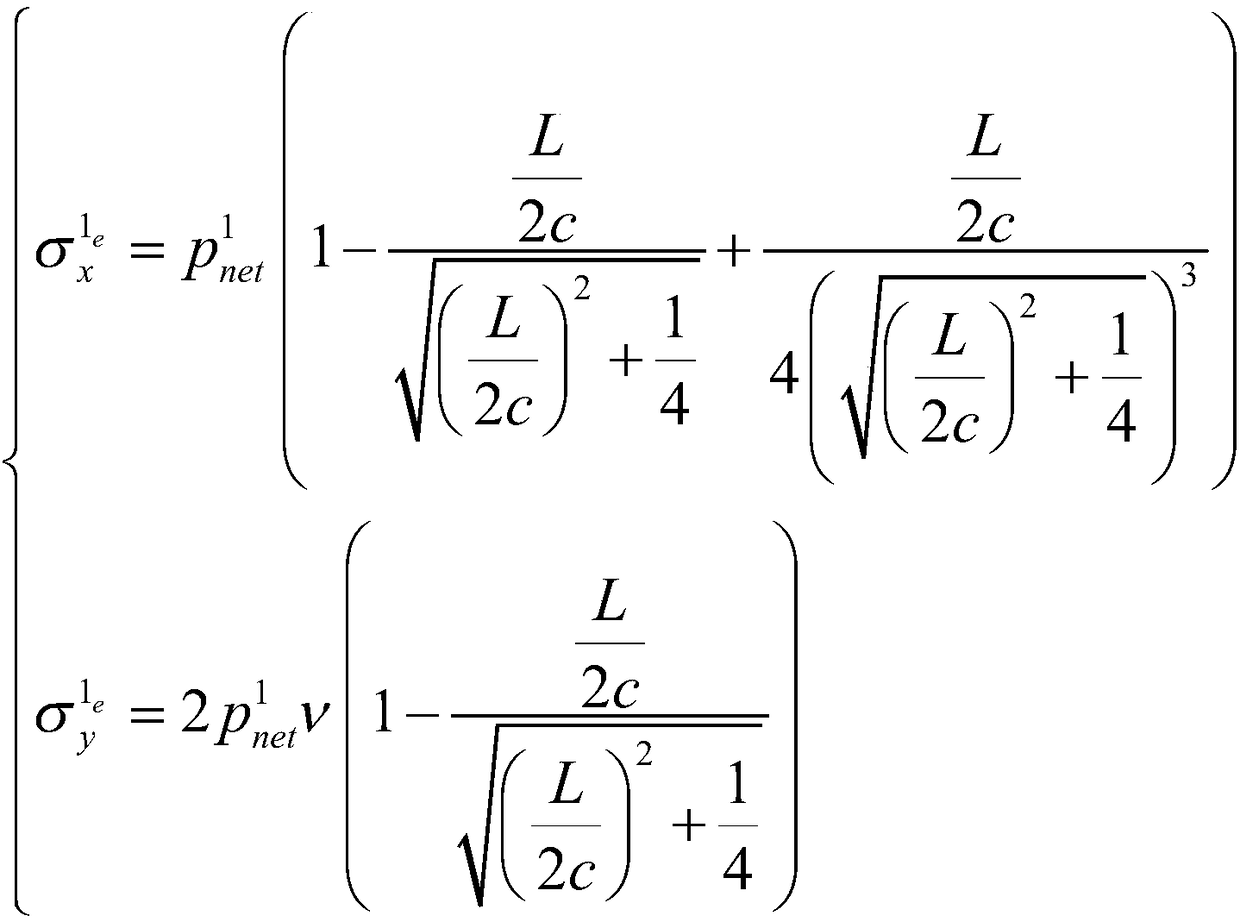

[0062]

[0063] In the formula: are the induced stresses produced by fractures at the last perforation cluster of the first fracturing stage in the direction of the minimum horizontal in-situ stress and the maximum horizontal in-situ stress, MPa; is the original net pressure of the fracture in the first fracturing stage, MPa; L is the horizontal distance from the center of the fracture to this point, m; c is the half-height of the fracture, m; v is the Poisson's ratio of the rock.

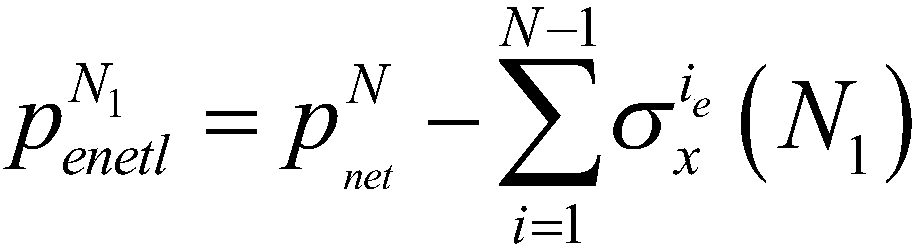

[0064] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com