Visual experimental system for fragmentation behaviors of reactor core melts in severe accidents of sodium cooled fast reactors

A serious accident, sodium-cooled fast reactor technology, applied in the field of nuclear energy, can solve the problems of unable to control the diameter and shape of the liquid column released by the melt, missing key information of the melt and coolant, and dead angles in the camera, so as to avoid the problems of equipment and operation Become overly complex, guarantee reference value, and study the effect of parameters comprehensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

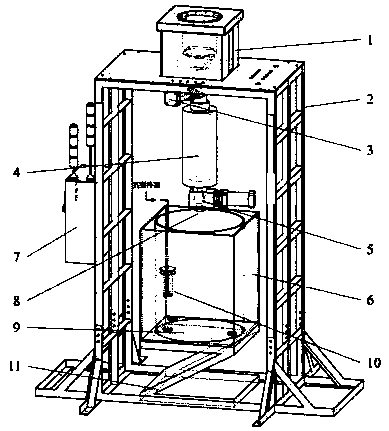

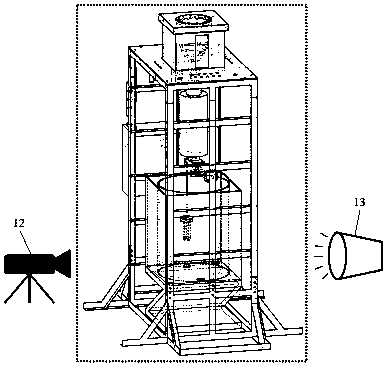

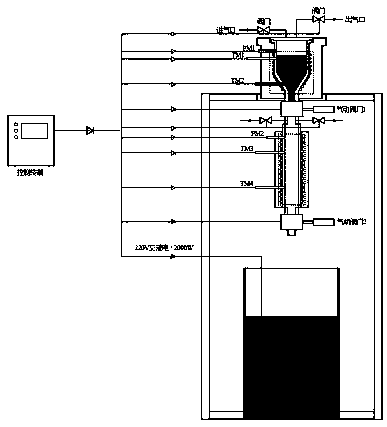

[0031] Such as figure 1 , 2 , 3, the visualized experimental system for the fragmentation behavior of the core melt when the sodium-cooled fast reactor serious accident provided by the present invention includes a support 2, a temperature-controllable annular resistance wire heating furnace 1 arranged on the support 2, a top The first high-temperature melt pneumatic valve 3 connected to the bottom of the temperature-controllable annular resistance wire heating furnace 1, the top and the bottom of the first high-temperature melt pneumatic valve 3 are connected to the pressurized heating pipe 4, the top is connected to the bottom of the pressurized heat supply pipe 4 The connected second high-temperature melt pneumatic valve 5, the visualization experiment container 6 arranged below the second high-temperature melt pneumatic valve 5 and the crushed product collector 9 arranged in the visualization experiment container 6, the visualization experiment container 6 adopts Made of t...

Embodiment 2

[0034] In this embodiment, the stent 2 of Embodiment 1 is specifically defined, as figure 1 As shown, the bracket 2 provided in this embodiment is a stainless steel structure, and a climbable ladder structure is designed on both sides, and the bracket 2 is designed to be detachable.

Embodiment 3

[0036] This embodiment limits the optimization scheme of the visualization experiment system of embodiment 1 and embodiment 2, such as figure 1 , 3 As shown, on the basis of Embodiment 1 and Embodiment 2, the experimental system provided by this embodiment also includes a control terminal 7, the control terminal 7 and the temperature-controllable annular resistance wire heating furnace 1, the first high-temperature melt pneumatic The valve 3, the pressurized heat supplement pipe 4, the second high-temperature melt pneumatic valve 5 are electrically connected to the heating module of the visualization experiment vessel. Through the control terminal 7, the opening and closing of the temperature-controllable annular resistance wire heating furnace 1, the first high-temperature melt pneumatic valve 3, the pressurized heating pipe 4, the second high-temperature melt pneumatic valve 5, and the heating function of the visualization experiment container can be realized. No, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com