Visual experimental system for shake features of molten fuel tank during severe accidents of sodium-cooled fast reactor

A severe accident, sodium-cooled fast reactor technology, applied in the field of nuclear energy, can solve problems such as dense fuel distribution and recritical danger, and achieve the effects of simple operation, comprehensive research parameters, and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

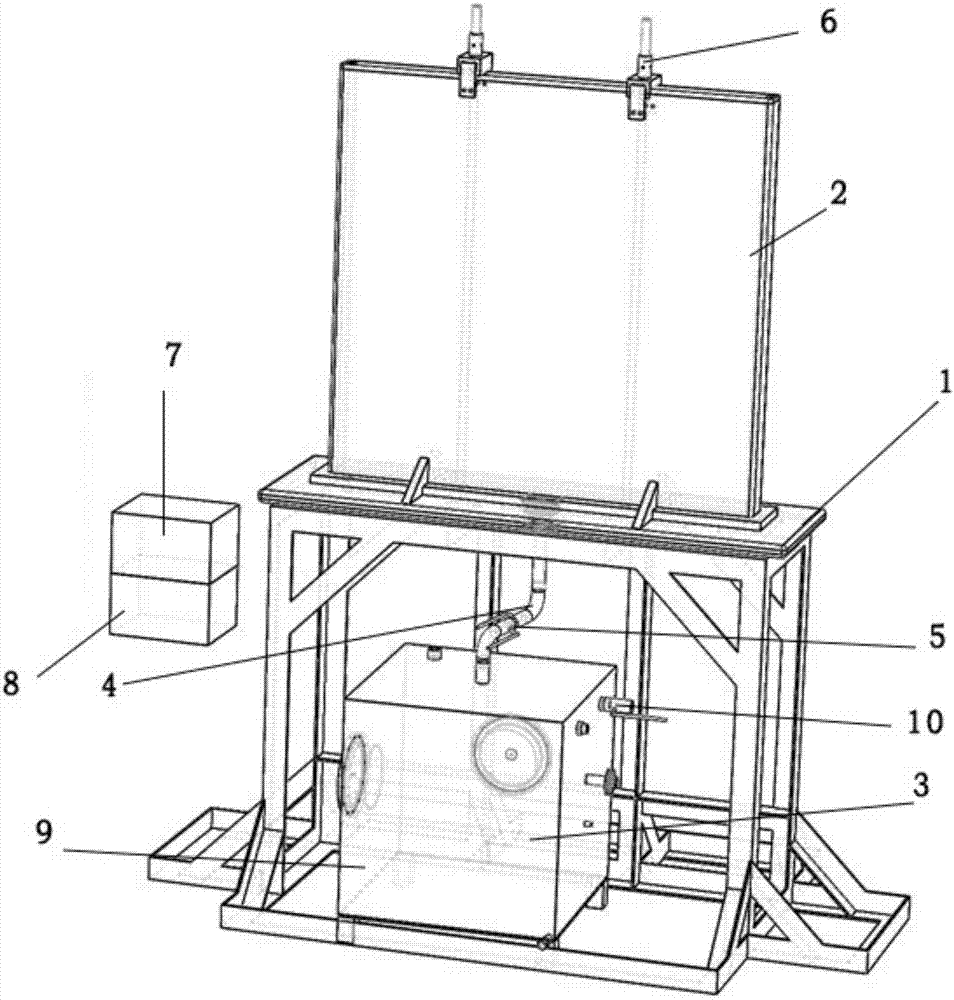

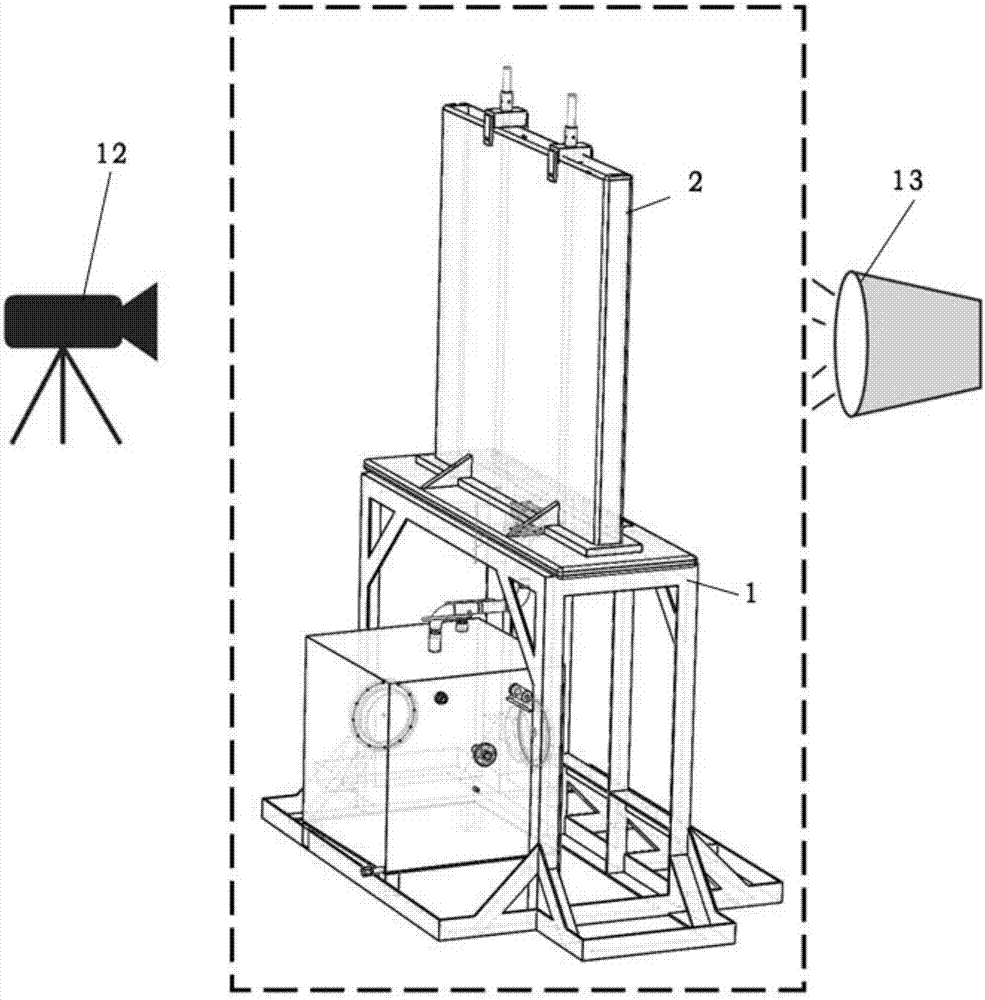

[0028] like figure 1 , 2 As shown in the figure, the visualized experimental system for the sloshing characteristics of the molten fuel pool during a severe accident of the sodium-cooled fast reactor provided by the present invention includes a support 1, a visualized experimental container 2 arranged on the support 1, a gas supply device 3, a gas conduit 4, and a jet valve. 5. Rod bundle structure 6, control module 7 and experimental environment monitoring module 8;

[0029] The bottom of the visual experiment container 2 is provided with a gas spout, and the gas spout of the visual experiment container 2 is connected to the gas supply device 3 through a gas conduit 4, and the gas jet valve 5 is installed on the gas conduit 4; the rod bundle structure 6 It is arranged on the top of the visual experimental container 2, and one end of it is inserted into the visual experimental container 2; the experimental environment monitoring module 8 is set in the visual experimental cont...

Embodiment 2

[0032] On the basis of Embodiment 1, the present invention further limits the specific structure of the visual experiment container 2 . like figure 1 , 2 shown:

[0033] The visual experiment container 2 provided in this embodiment can be one of a cuboid, a cube and a cylinder, and the top of the visual experiment container 2 of a cuboid, a cube and a cylinder is open. The specific shape of the visual experiment container 2 can be selected according to the needs of the experiment. For example, if two-dimensional experimental observation is to be performed, a thin-shaped visual experiment container 2 such as a rectangular parallelepiped-shaped visual experiment container 2 is selected, and its observation effect is better; For three-dimensional experimental observation, you can choose a cube or cylinder-shaped visual experiment container 2 . Among them, in order to facilitate the cleaning of the visual experiment container 2 after the experiment is completed, a discharge val...

Embodiment 3

[0037] In this embodiment, on the basis of Embodiment 1 and Embodiment 2, the gas supply device 3 is further described in detail. like figure 1 , 2As shown, the gas supply device 3 includes a main body 9, and a cavity for accommodating gas is opened in the main body 9. The top of the main body 9 is provided with an interface for connecting the gas conduit 4 and a pressure gauge, and the interface communicates with the cavity. The main body 9 is made of stainless steel, and its overall shape is a cube. One side of the main body 9 is provided with an intake valve 10 , which communicates with the cavity and is connected to the control module 7 . Under normal circumstances, there is gas stored in the main body 9, and its internal air pressure is relatively high, which meets the requirements of the experiment, but after many uses, the air pressure of the gas stored in the main body 9 is insufficient to support the next experiment. At this time, the main body 9 needs to be filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com