A variable-volume superimposed vacuum drying incubator

A technology of vacuum drying and constant temperature box, which is applied in the direction of drying solid materials without heating, drying solid materials, drying, etc., can solve the problems of slow temperature control balance, large floor space, and many equipment, etc., and achieves easy maintenance and occupancy. The effect of small floor area and large effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

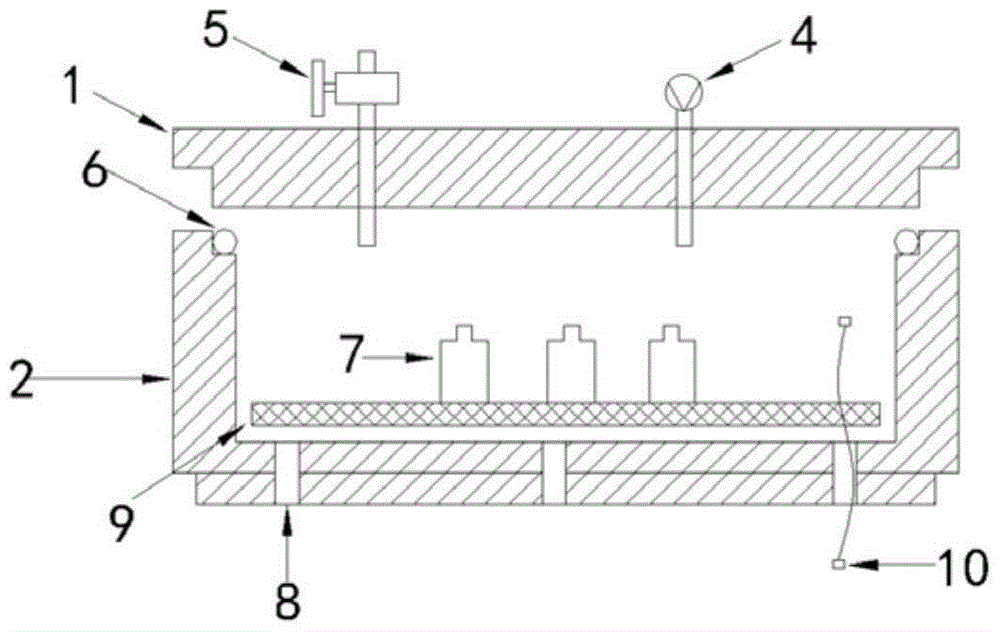

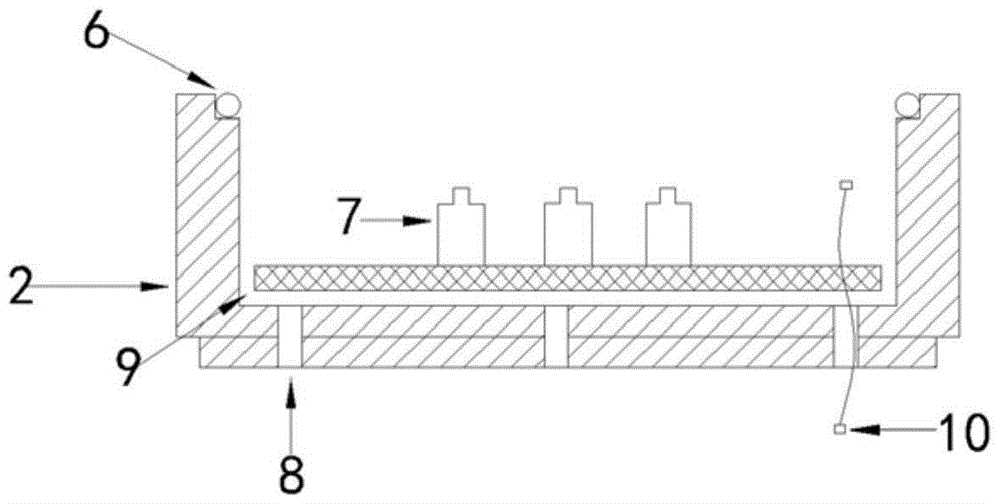

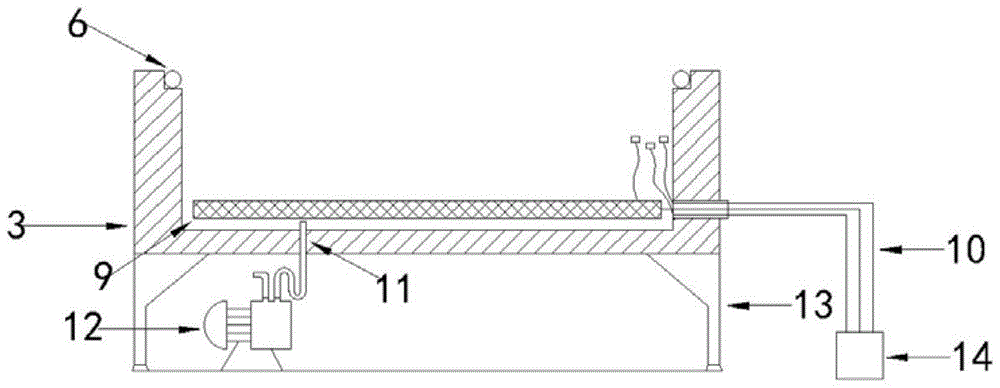

[0023] Such as Figure 1-3 As shown, a variable-volume superimposed vacuum drying incubator includes: an upper cover 1 sealed and connected sequentially from top to bottom, a plurality of stackable boxes 2 and a bottom box 3, and the upper cover 1 is equipped with There is an air release valve 5 for controlling the air flow in the box, and a vacuum gauge 4 for observing the air pressure in the box. Each stackable box body 2 adopts a vertical square inner wall, and its top side wall is provided with a concave step and a sealing strip 6 is provided in the concave part, and the bottom of the stackable box body 2 or the bottom of the upper cover 1 above it Matching, the bottom box body 3 also adopts a vertical square inner wall, and its top side wall is also provided with a concave step and a sealing strip 6 is provided at the concave part to match the bottom of the stackable box body 2 above it; Gravity and negative pressure are used to seal the gap between the upper cover and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com