Seed guide device on the hole-on-membrane flat seeding machine

A straight and diversion trough technology, which is applied to planter parts, interval quantitative sowing machinery, sustainable manufacturing/processing, etc., can solve the problem of not being able to observe the working status of the equipment, not being able to realize it, and not being able to detect the quality of the sowing in time, etc. Problems, to achieve the effect of convenient equipment maintenance and parts replacement, prevent the phenomenon of missed broadcasting, and save running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

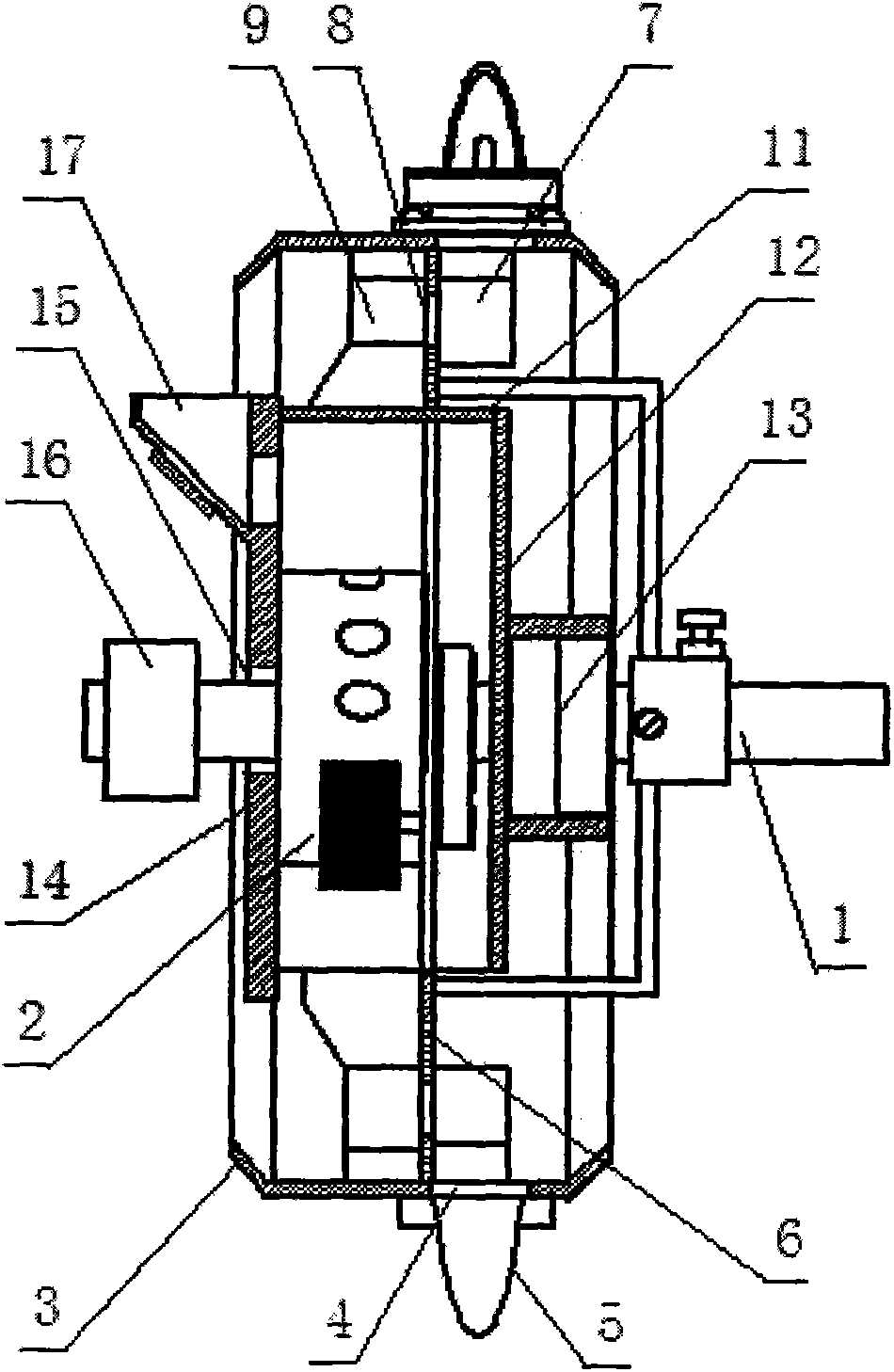

[0023] Such as figure 1 As shown, the seed guide device on the hole-on-membrane direct seeding machine is a wheel structure, including a quantitative seed meter 2 fixed on the rotating shaft 1 and a drum 3 on the outer periphery of the equipment, and seed holes 4 uniformly arranged on the drum 3 The seeder 5 of duckbill formula is housed.

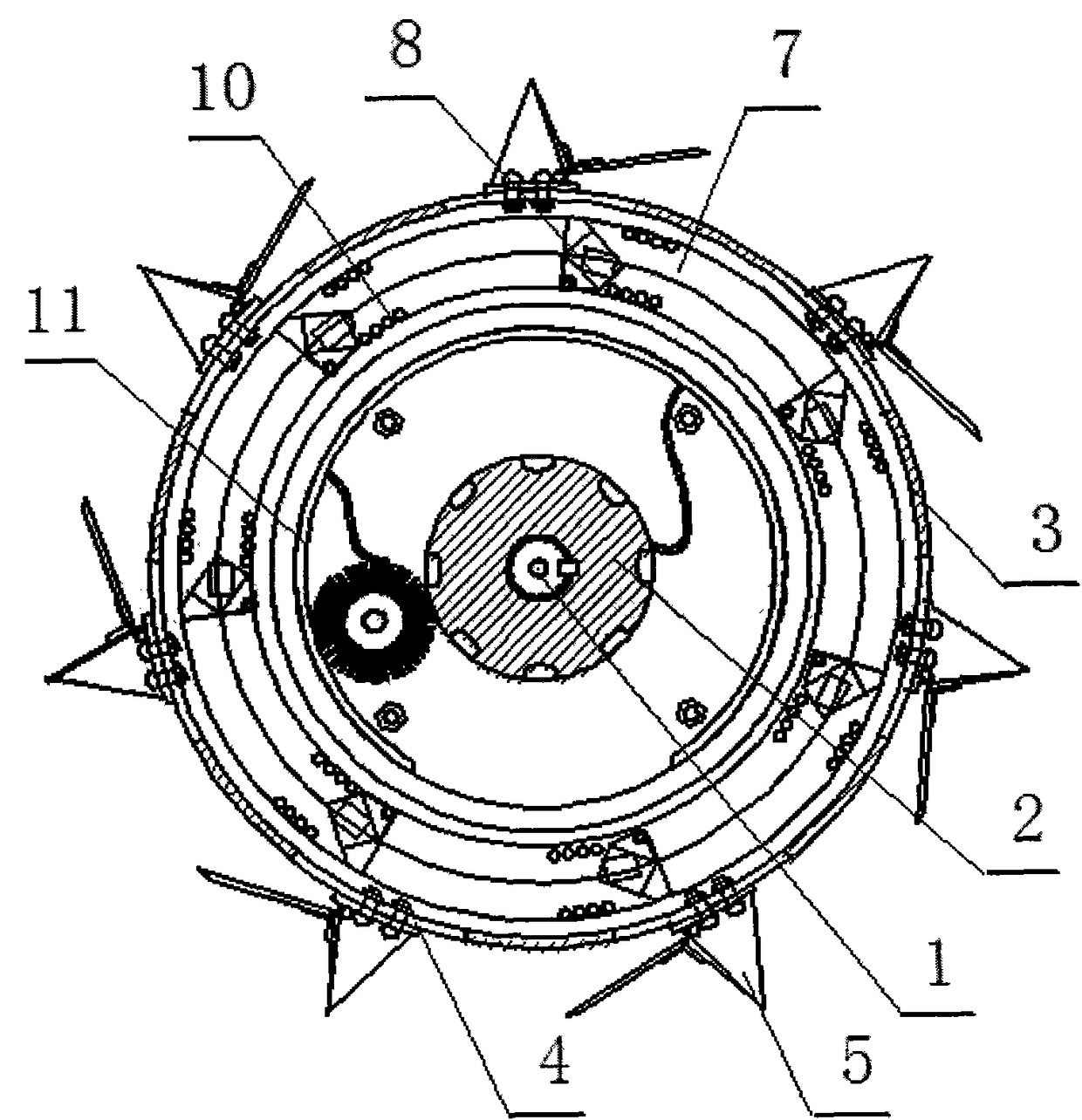

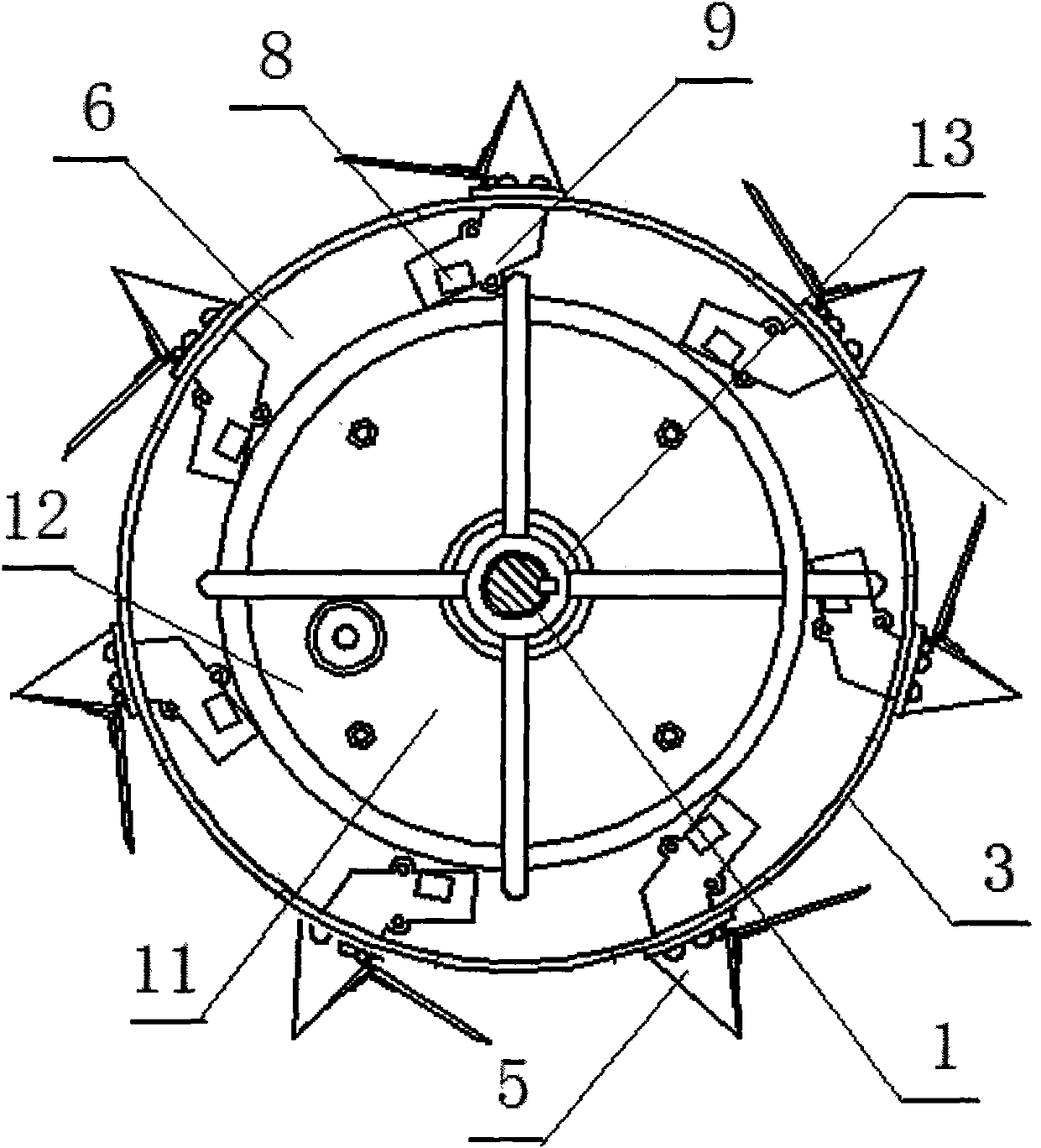

[0024] The inner side of the drum 3 is equipped with annularly distributed seed diversion grooves, and the seed diversion grooves are divided into left and right sections, see figure 2 with image 3 , The two sections of seed diversion grooves are separated by an annular partition 6 vertically fixed on the drum 3 . The left section of the seed diversion groove is formed by inserting and lapping end to end of several arc-shaped split diversion grooves 7 . The head end of every split flow diversion groove 7 is an opening, and the tail end of the adjacent next split diversion groove 7 is inserted therefrom. The seeds enter the seed divers...

example 2

[0029] Such as Figure 4 Shown, the fixed frame 18 of this device comprises the horizontal U-shaped frame 19 of rear opening, and the bearing seat 20 of rotating shaft 1 is equipped with in the left and right crossbeam inner side of U-shaped frame 19 rear ends, and horizontal adjustment bar 21 is equipped with at the head end, The horizontal adjustment rod 21 is provided with a height adjustment four-bar mechanism. The top of U-shaped frame 19 is equipped with U-shaped vertical beam 22. A seed box 24 is housed on the U-shaped vertical beam 22, and the conveying pipe 25 at the bottom of the seed box 24 is connected with the feeding funnel 17. The locking pin 26 of the quantitative seed meter 2 is equipped with on the top of the U-shaped frame 19 middle sections, and the afterbody is equipped with a seed hole sealing pressure roller 23 by an assembly rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com