Screw detection method and device

A detection method and screw technology, which is applied in the field of industrial manufacturing, can solve the problems of low screw detection efficiency and the inability of non-indexing disc screw detection machines to accurately control screw detection, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

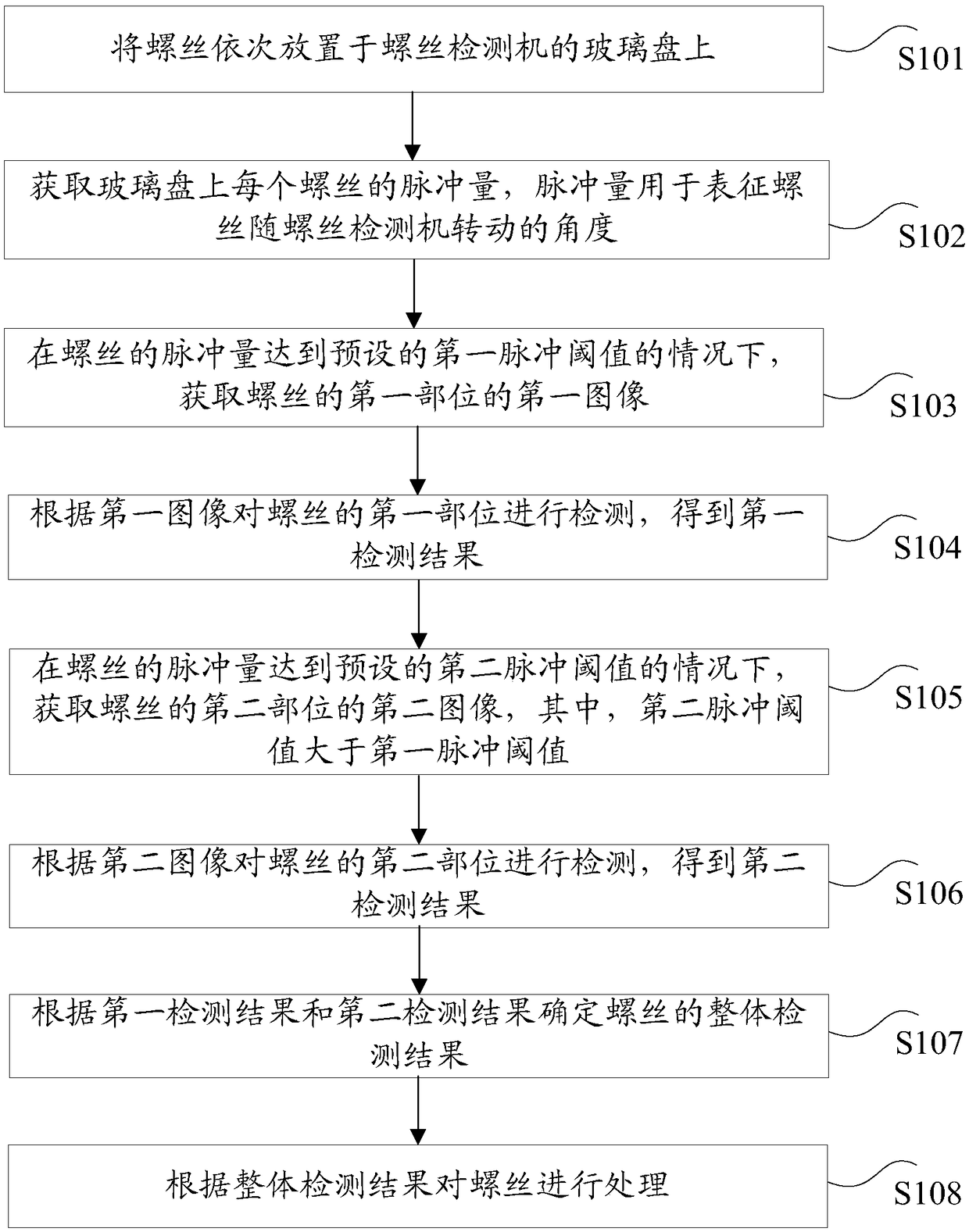

[0025] According to an embodiment of the present invention, a screw detection method is provided, which is applied to a screw detection machine, such as figure 1 As shown, the method includes:

[0026] S101, placing the screws on the glass plate of the screw detection machine in sequence;

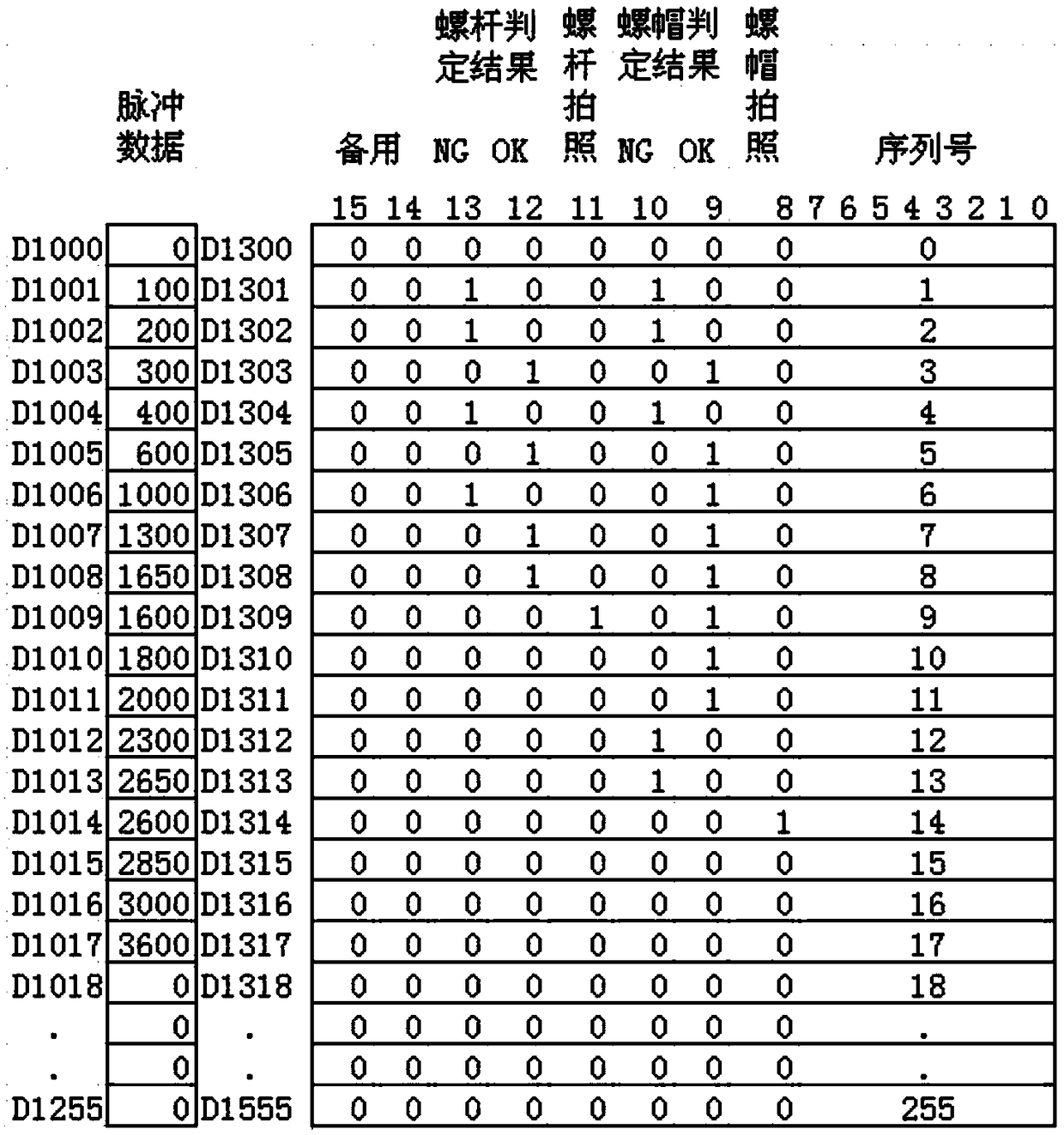

[0027] S102, acquiring the pulse amount of each screw on the glass plate, the pulse amount is used to represent the angle at which the screw rotates with the screw detector;

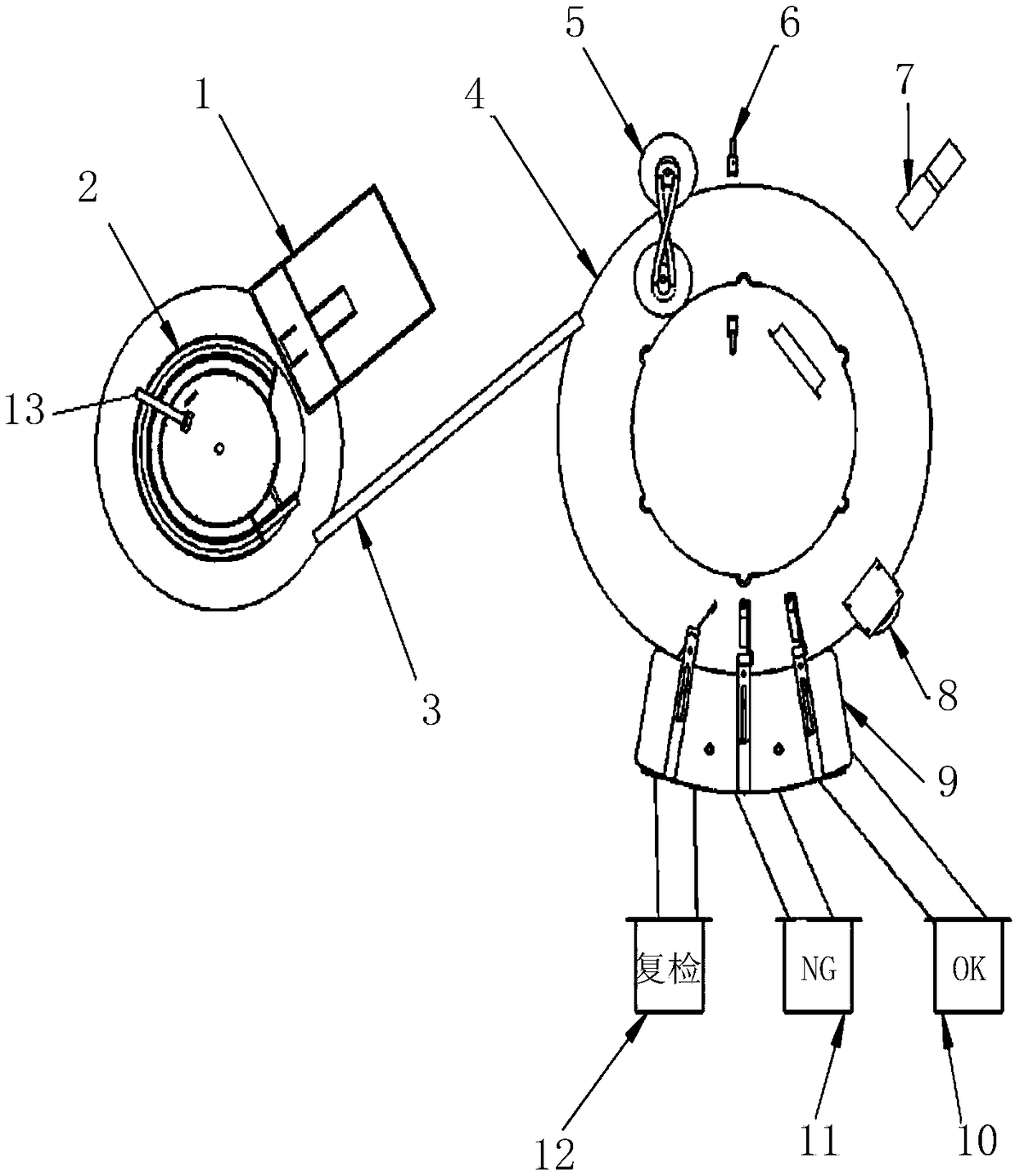

[0028] In the related art, the precise control of the screw cannot be realized for the non-dividing disc screw detection machine. Therefore, in the embodiment of the present invention, a screw detection method is proposed to realize the non-dividing disc screw detection. The screw can be precisely controlled in the machine. For example, if figure 2 As shown in the non-indexing disk detector, there is a sensor 6 in the non-indexing disk detector, and the screw is fed into the optical glass disk of the non-grading d...

Embodiment 2

[0073] According to an embodiment of the present invention, a screw detection device for implementing the above screw detection method is also provided, such as Figure 4 As shown, the device includes:

[0074] 1) The distributing unit 401 is used to place the screws sequentially on the glass plate of the screw inspection machine;

[0075] 2) The first acquisition unit 402 is used to acquire the pulse amount of each screw on the glass plate, and the pulse amount is used to represent the angle at which the screw rotates with the screw detector;

[0076] 3) A second acquisition unit 403, configured to acquire a first image of a first part of the screw when the pulse amount of the screw reaches a preset first pulse threshold;

[0077] 4) a first detection unit 404, configured to detect the first part of the screw according to the first image, and obtain a first detection result;

[0078] 5) A third acquisition unit 405, configured to acquire a second image of a second part of t...

Embodiment 3

[0088] According to an embodiment of the present invention, a storage medium is further provided, and the storage medium includes a stored program, wherein the above screw detection method is executed when the program is running.

[0089] Optionally, in this embodiment, the storage medium is configured to store program codes for performing the following steps:

[0090] S1, place the screws on the glass plate of the screw detector in sequence;

[0091] S2. Obtain the pulse amount of each screw on the glass plate, the pulse amount is used to represent the angle at which the screw rotates with the screw detector;

[0092] S3. Acquire a first image of a first part of the screw when the pulse amount of the screw reaches a preset first pulse threshold;

[0093] S4. Detect the first part of the screw according to the first image, and obtain a first detection result;

[0094] S5. Acquire a second image of a second part of the screw when the pulse amount of the screw reaches a preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com