Negative pressure cleaning machine and method for cleaning and disinfecting thereof

A negative pressure cleaning, cleaning and disinfection technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, disinfection, etc., and can solve the problem of single application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

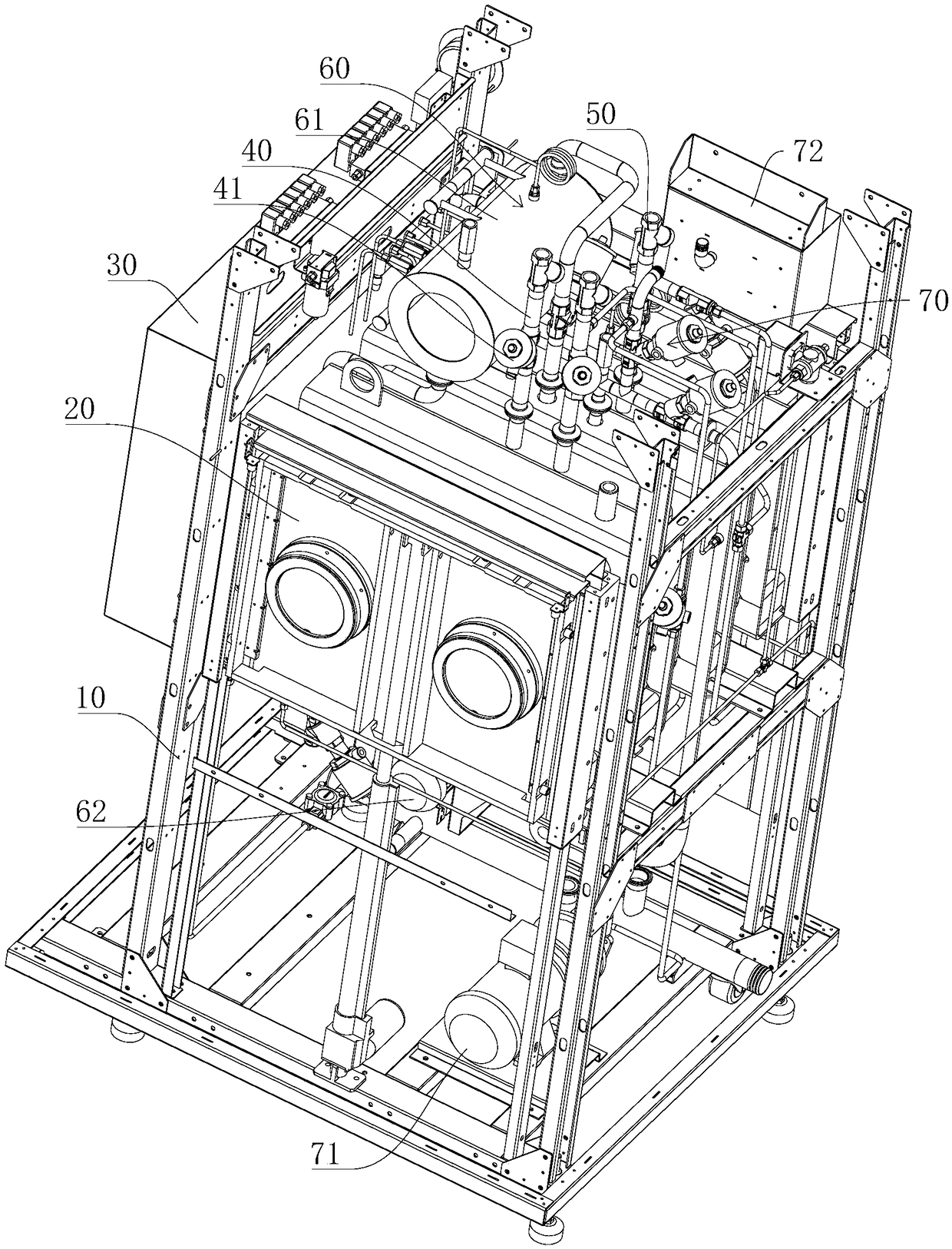

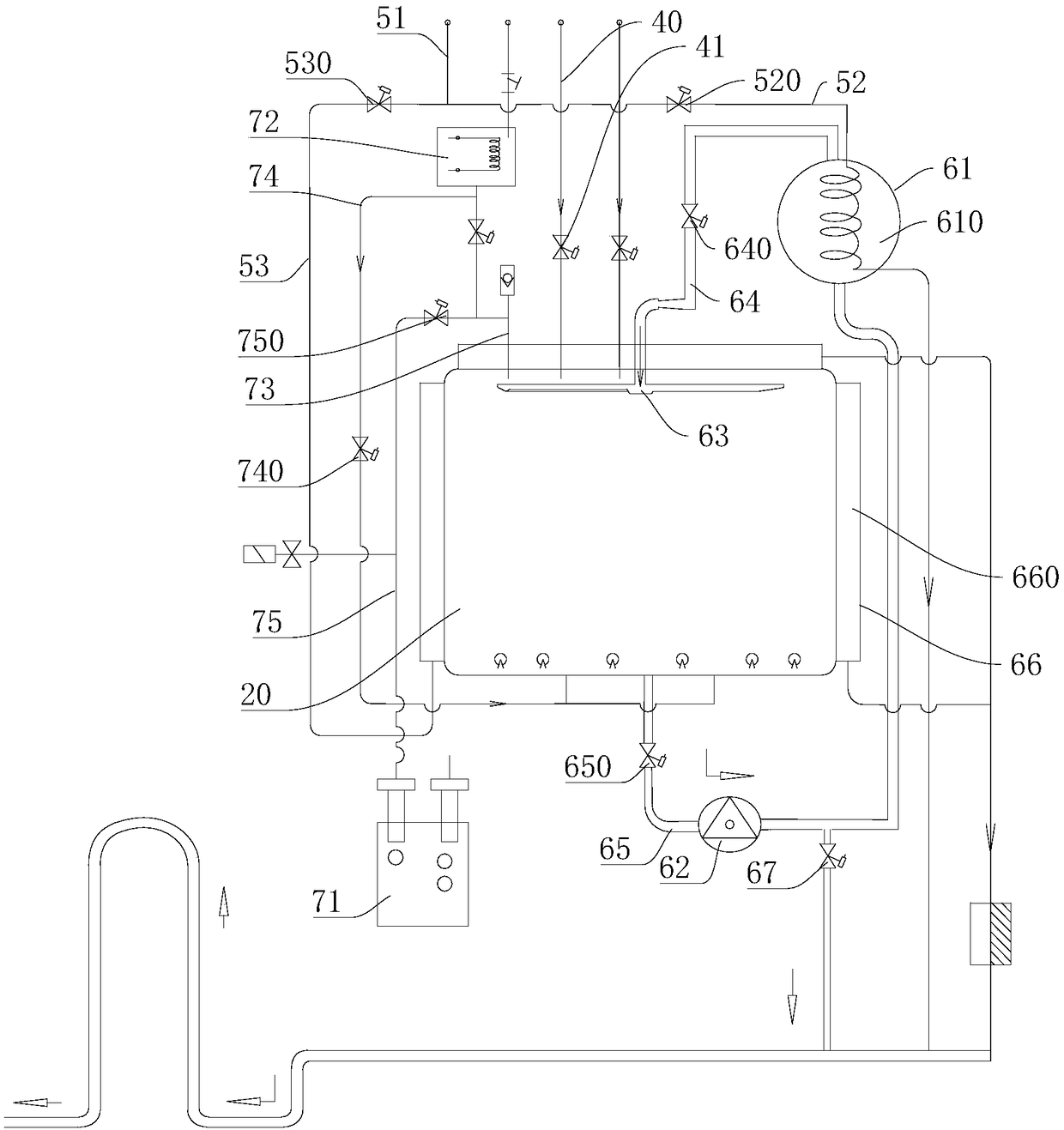

[0034] Please refer to figure 1 and figure 2 As shown, Embodiment 1 of the present invention provides a negative pressure cleaning machine, including a frame 10 and a cleaning cabin 20 installed on the frame 10, and the negative pressure cleaning machine also includes a control system 30 and controls the operation through the control system 30. Liquid supply mechanism 40, steam heating system 50, circulation heating system 60 and vacuum mechanism 70; The control system 30 here is a PLC controller, also can be other controllers, can implant control software by programming, to control the automatic operation of equipment run. The steam heating system 50 is used to heat the sidewall of the cleaning cabin 20; the liquid circulation system is used to exchange heat between the cleaning cabin 20 and the liquid outside the cleaning cabin 20; the vacuum mechanism 70 is used to pump the cleaning cabin 20 Vacuum and pressure relief operations; Circulation heaters are devices that heat...

Embodiment 2

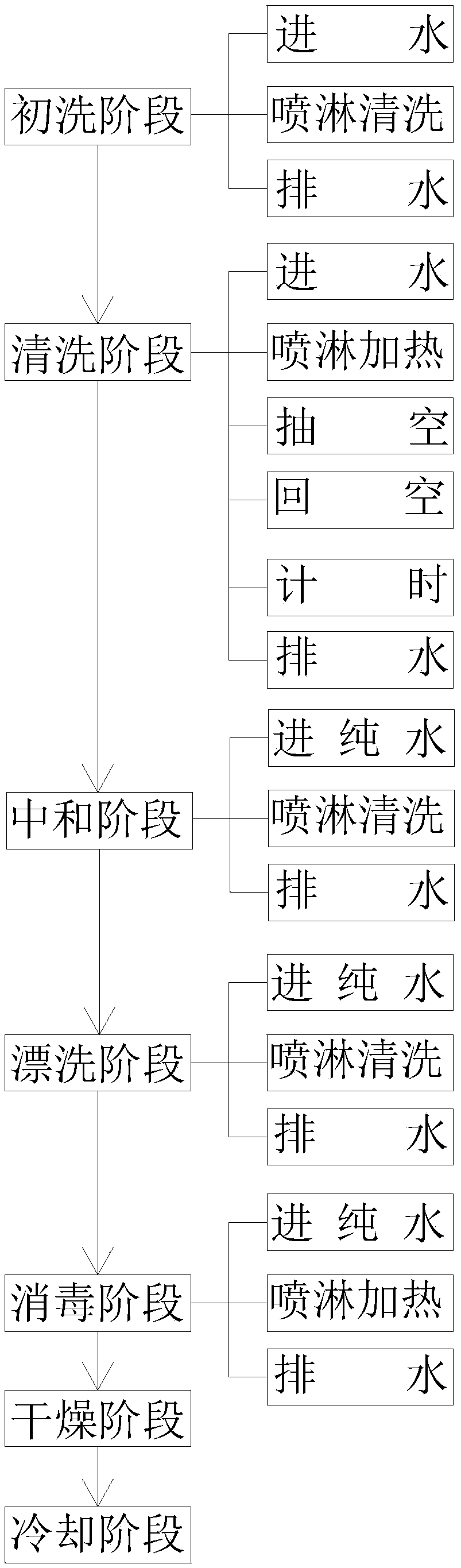

[0041] Please refer to image 3 As shown, embodiment 2 of the present invention provides a kind of method that utilizes negative pressure cleaning machine to carry out cleaning and disinfection, comprises following work stage:

[0042] Initial washing, washing, neutralizing, rinsing, sanitizing, drying and cooling stages. Its detailed procedure is as follows:

[0043] The preliminary washing stage includes the steps of water intake, spray cleaning and drainage.

[0044] The water inlet process is: open the air return valve, open the circulating water inlet valve, and open the circulating water outlet valve, open the pure water valve for two seconds to enter the water, the system detects that the water level reaches the spray water level, close the pure water valve, and stop water injection; When the time exceeds the set time, the system will give an alarm and control the closure of the pure water valve.

[0045] The spray cleaning process is: start the water pump, start tim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap