Material washing machine

A cleaning machine and material technology, applied in the field of cleaning machines, can solve problems such as high labor intensity, low production efficiency, and poor sanitary conditions, and achieve the effects of high automation, large cleaning volume, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

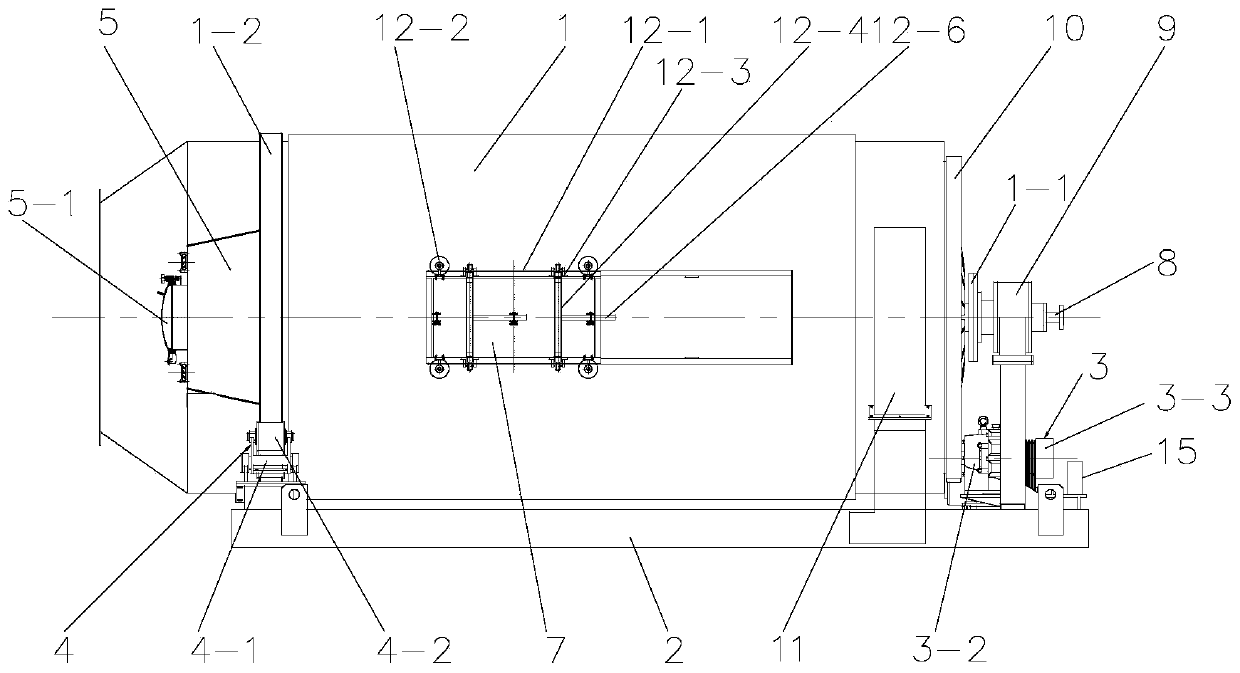

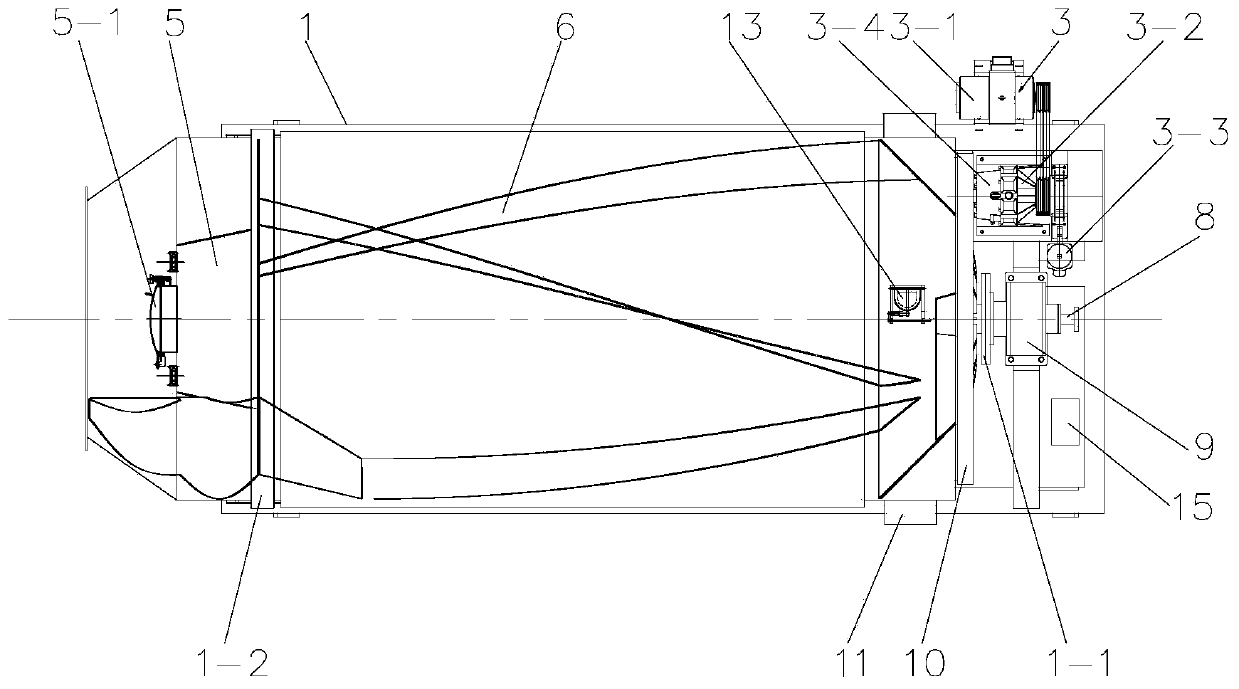

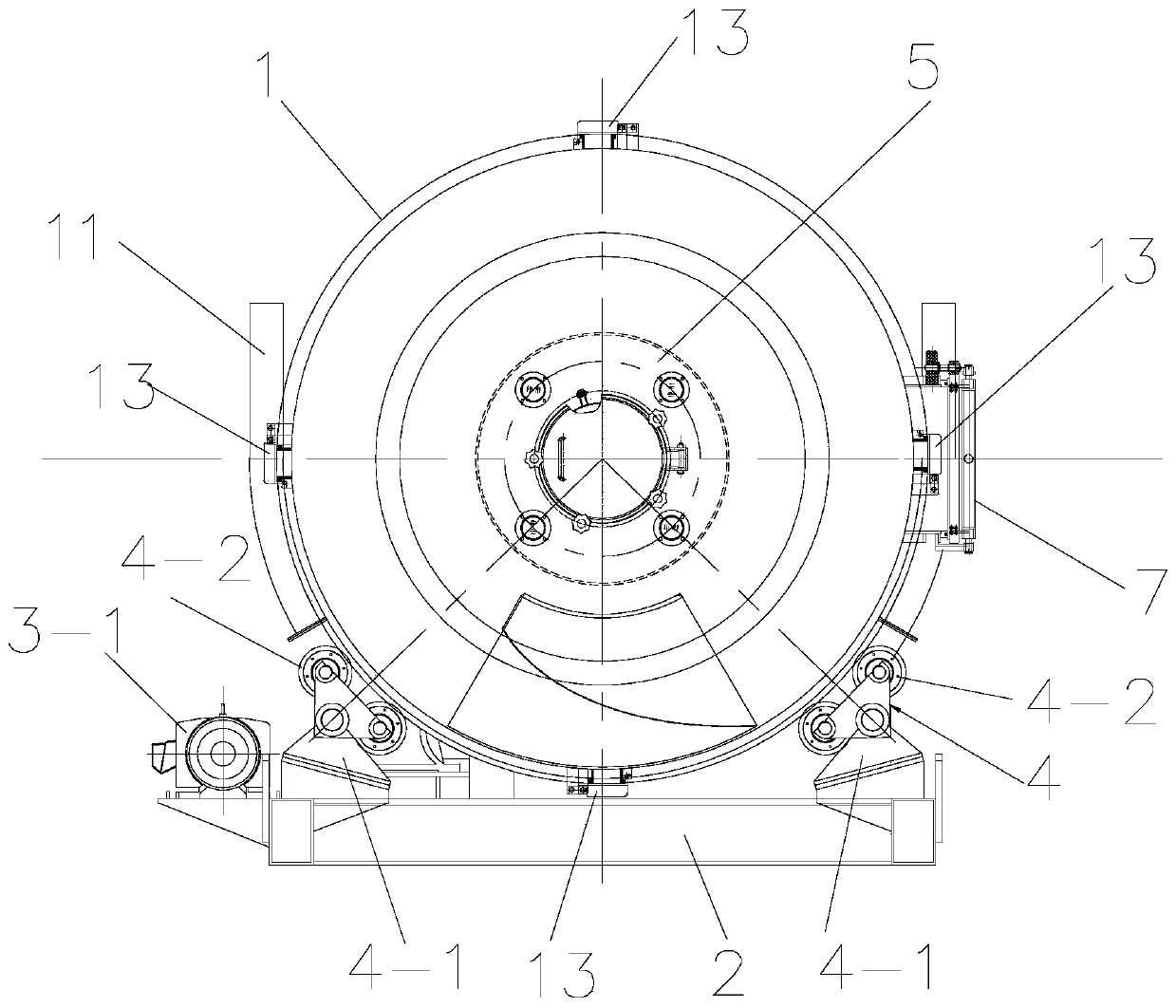

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10, a material cleaning machine includes a cylinder 1, a base 2, a cylinder rotating mechanism 3, a supporting wheel assembly 4, a water seal compartment 5, Spiral belt 6, feed gate 7, hollow shaft 8, bearing seat 9, ring gear 10, drain gate 13 and PLC controller 15;

[0026] One end of the cylinder 1 is provided with an end plate 1-1 and a ring gear 10, and the other end is provided with a rolling ring 1-2. The cylinder 1 has a feed port and a discharge port, and the spiral belt 6 is fixed on the cylinder On the inner wall of the body 1, a water-sealed compartment 5 is set at one end of the cylinder 1 and is fixedly connected with one end of the spiral belt 6, and the water-sealed compartment 5 has a discharge port 5-1 and communicates with one end of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com