Manufacturing method for five-in-one adjustable spanner

The technology of an adjustable wrench and its manufacturing method, which is applied in the field of wrenches, can solve the problems of narrow practical use and single function of the adjustable wrench, and achieve the effects of easy portability, simple operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

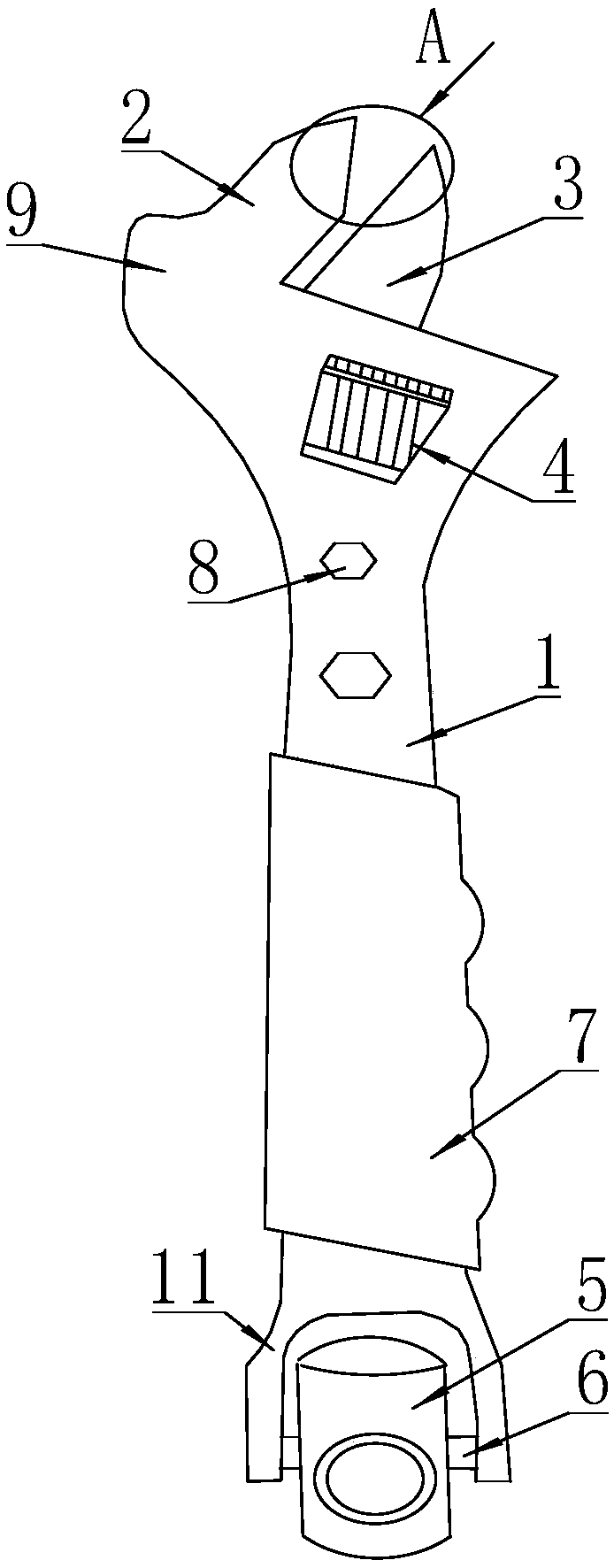

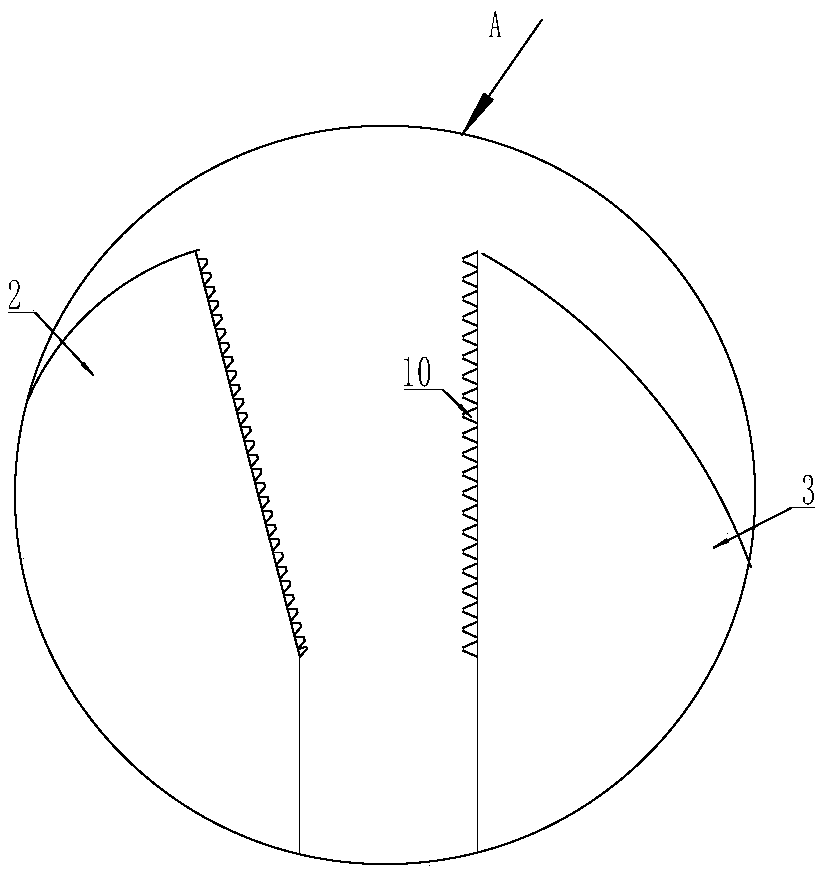

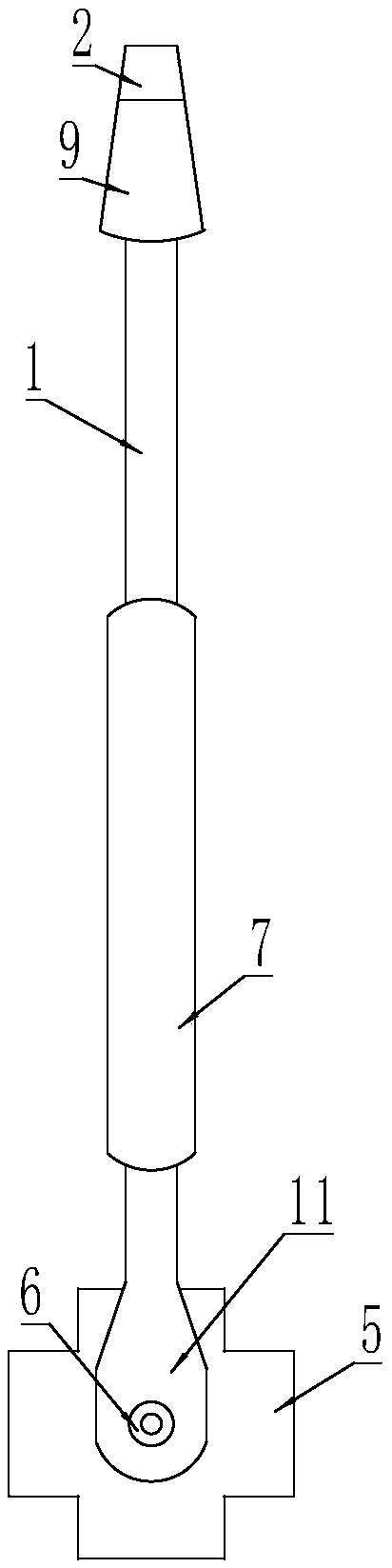

Embodiment 1

[0020] The upper end of one side of the handle 1 is provided with a fixed jaw 2, the lower end of the outer side of the fixed jaw 2 is provided with a hammer head 9, the top end of the handle 1 is provided with a sliding groove, the movable jaw 3 is arranged in the sliding groove, and the upper end of the handle 1 is provided with a dial groove, and the dial groove The upper end of the sliding groove communicates with the lower end of the sliding groove, and the screw dial 4 is arranged in the dial groove, and the rack at the lower end of the movable jaw 3 is engaged with the spiral dial 4 correspondingly, and the upper part of the fixed jaw 2 is provided with an inclined surface, and the fixed jaw 2 The inclined surface of the movable jaw 3 and the inner upper part of the movable jaw 3 are provided with a tooth surface 10, the lower end of the tooth surface 10 on the movable jaw 3 is aligned with the lower end of the tooth surface 10 on the fixed jaw 2, and the lower vertical s...

Embodiment 2

[0024] The size of the inner hexagon hole 8 is 8-36mm.

Embodiment 3

[0026] The sleeve 5 is a cross-shaped sleeve, one or two holes of the sleeve 5 are hexagonal holes, and the remaining holes are twelve-angle holes. The specification of the sleeve 5 is 10-32mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com