Electrothermal film and heating structure

An electric heating film and heating layer technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve problems such as short circuits and safety hazards, and achieve the effect of reducing the risk of current leakage and large contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

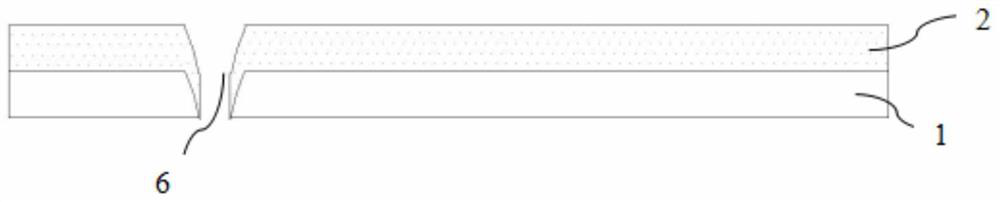

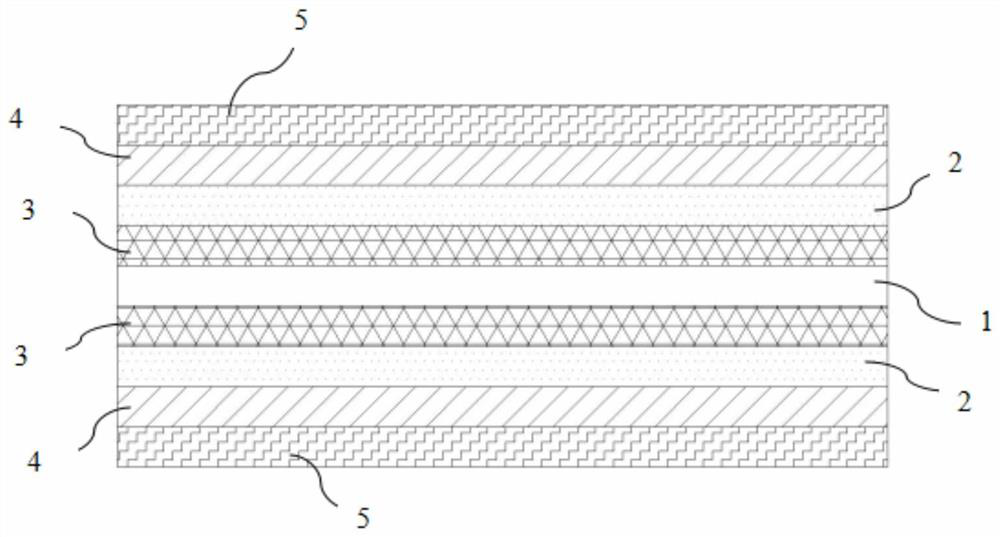

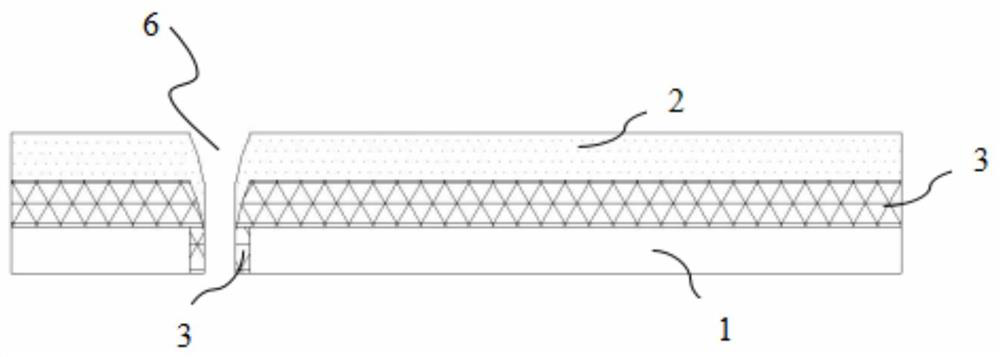

[0062] The process of laying the electric heating film by the electric heating film wet method includes:

[0063] Provides a power density of 230W / m 2 The carbon nanotube heating film is used as the heating film;

[0064] Lay glass fiber cloth layers with a thickness of 0.2mm on the opposite sides of the heating film as a fireproof insulation layer;

[0065] Lay aluminum foil with a thickness of 7 μm on the side of the glass fiber cloth away from the heating film as a shielding layer (the square resistance is 0.02Ω / sq), and the area ratio of the heating film to the shielding layer is 1:0.83;

[0066] Lay a polyester film with a thickness of 0.025mm on the side of the shielding layer away from the fireproof insulation layer as the insulating layer;

[0067] A polyvinyl chloride film bag with a thickness of 0.6mm is packaged on the outer surface of the insulating layer as a protective layer, and the final electric heating film structure is as follows: figure 2 shown.

[006...

Embodiment 2

[0070] The process of laying the electric heating film by the electric heating film wet method includes:

[0071] The power density is 230W / m 2 The carbon nanotube heating film is used as the heating film;

[0072] Lay basalt fiber cloth with a thickness of 0.2mm on the opposite sides of the heating film as a fireproof insulation layer;

[0073] Lay aluminum foil with a thickness of 7 μm on the side of the glass fiber cloth away from the heating film as a shielding layer (the square resistance is 0.02Ω / sq), and the area ratio of the heating film to the shielding layer is 1:0.83;

[0074] Lay a polyester film with a thickness of 0.025mm on the side of the shielding layer away from the fireproof insulation layer as the insulating layer;

[0075] A polyvinyl chloride film bag with a thickness of 0.6mm is packaged on the outer surface of the insulating layer away from the shielding layer as a protective layer, and the formed electric heating film structure is as follows: figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com