An automatic turning tool for generator collector ring

A slip ring and automatic lathe technology, applied in the direction of tool clamps, manufacturing tools, turning equipment, etc., can solve the problems of low machining accuracy and poor safety, save the time of welding, improve the precision of lathes, and improve the lathes quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

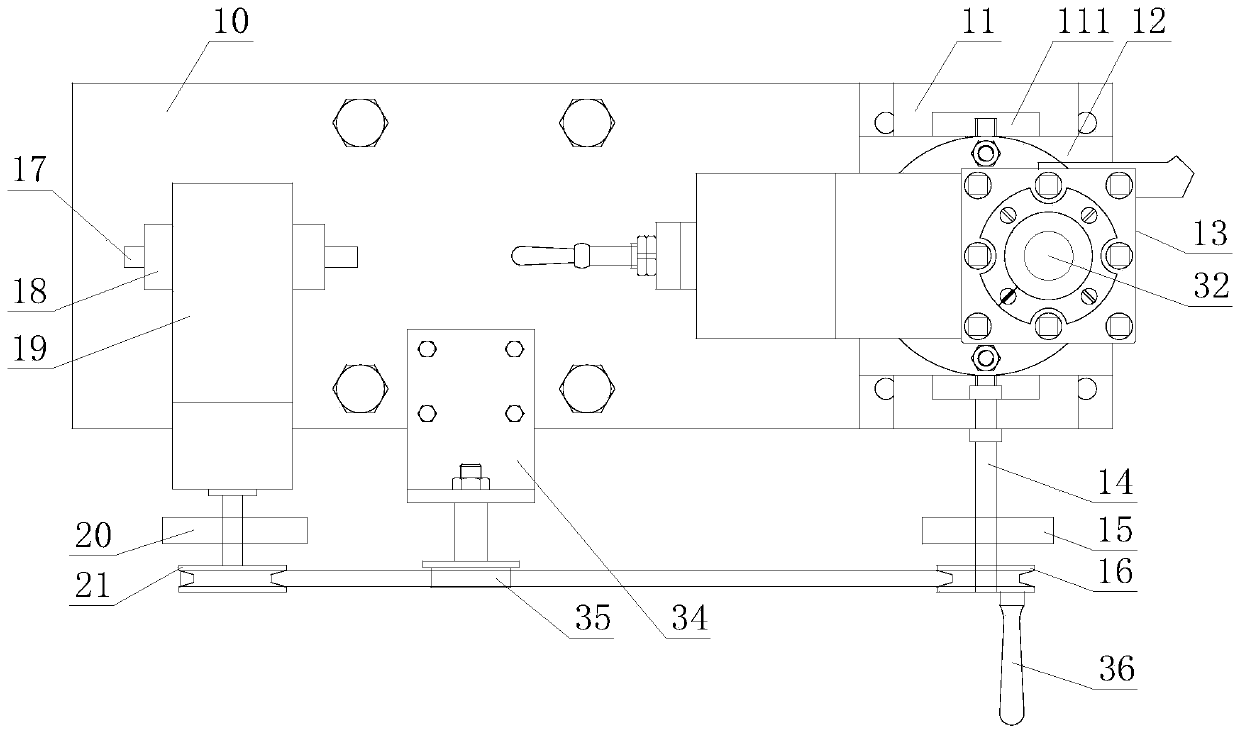

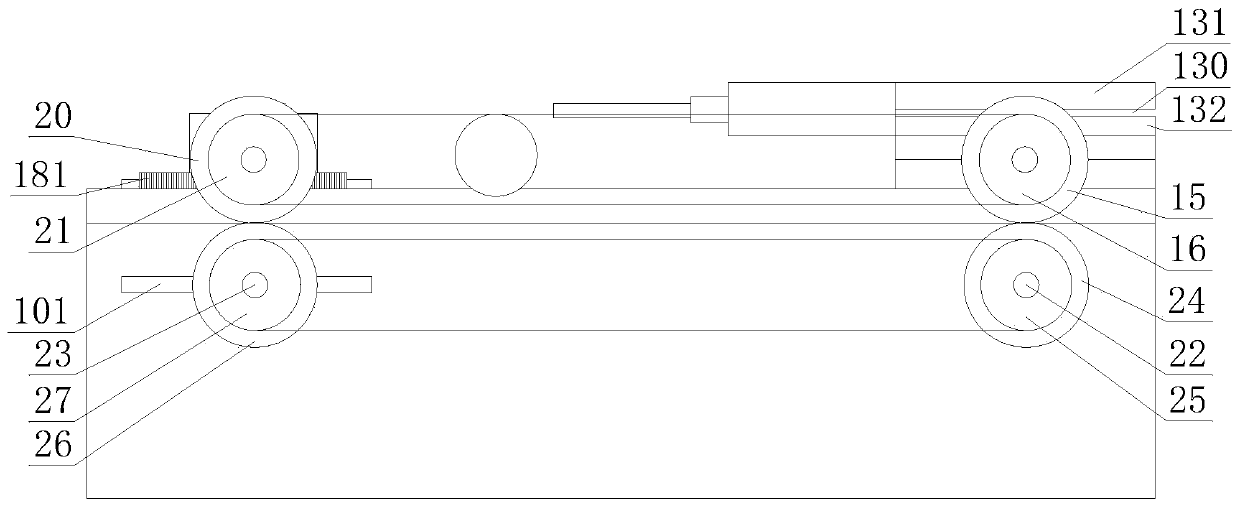

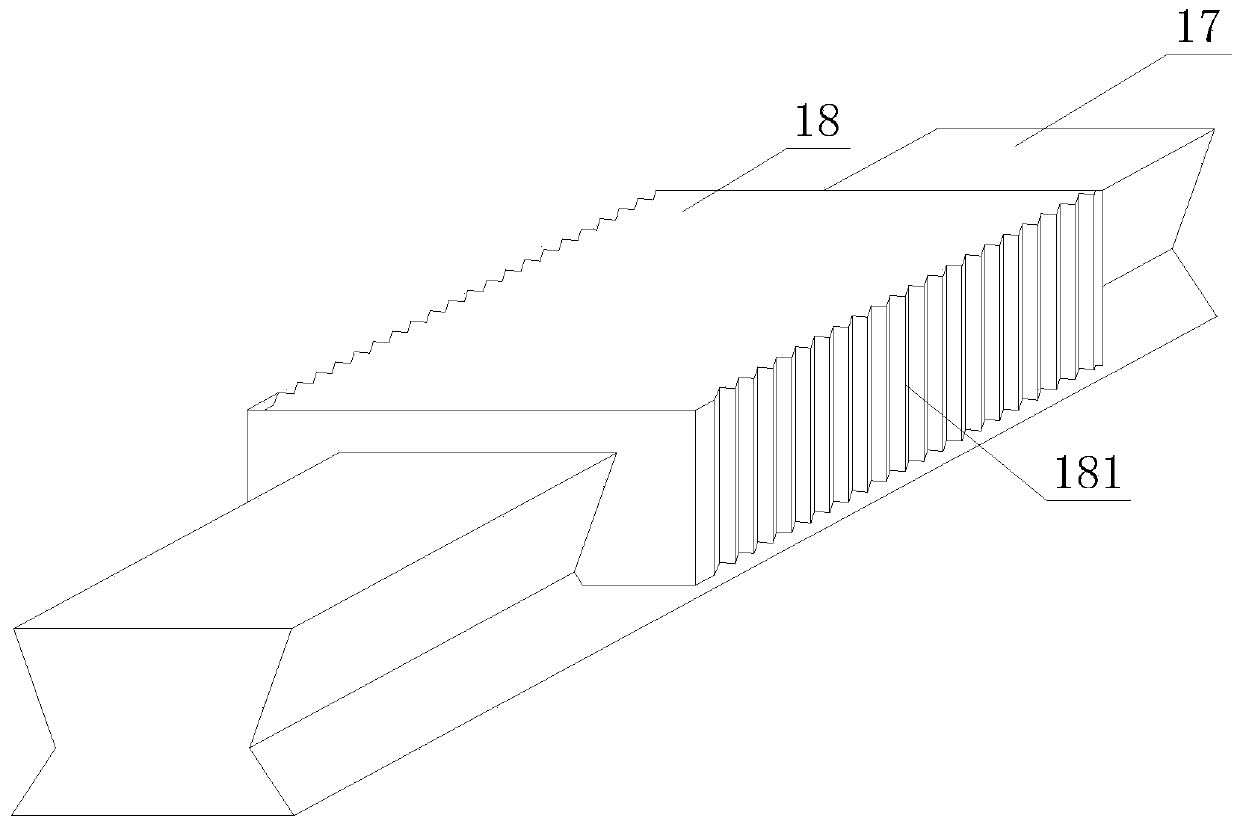

[0022] An automatic turning tool for generator slip rings, such as Figure 1-4As shown, it includes a workbench 10, the first guide rail 11 arranged longitudinally is installed on the workbench 10, the first slide block 12 is slid on the first guide rail 11, and guide grooves are provided on both sides of the first guide rail 11, the first slide Block 12 is provided with guide projection, and the first slide block 12 is installed in the guide groove of the first guide rail 11 by guide projection, prevents that the first slide block 12 breaks away from the first track 11 when moving, installs on the first slide block 12 There is a knife rest 13, the knife rest 13 is fixed on the first slide block 12 by bolts, and also includes a screw mandrel 14, the first guide rail 11 is provided with a strip-shaped groove 111, and the bottom surface of the first slide block 12 is fixed with a convex In this embodiment, the bump and the first slider 12 are integrated, the bump extends into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com