A SBR partial nitrosation process matching anaerobic ammonium oxidation

A technology of anaerobic ammonium oxidation and nitrosation, which is applied in the field of SBR partial nitrosation matching with anaerobic ammonium oxidation, and can solve problems such as increased operating costs and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

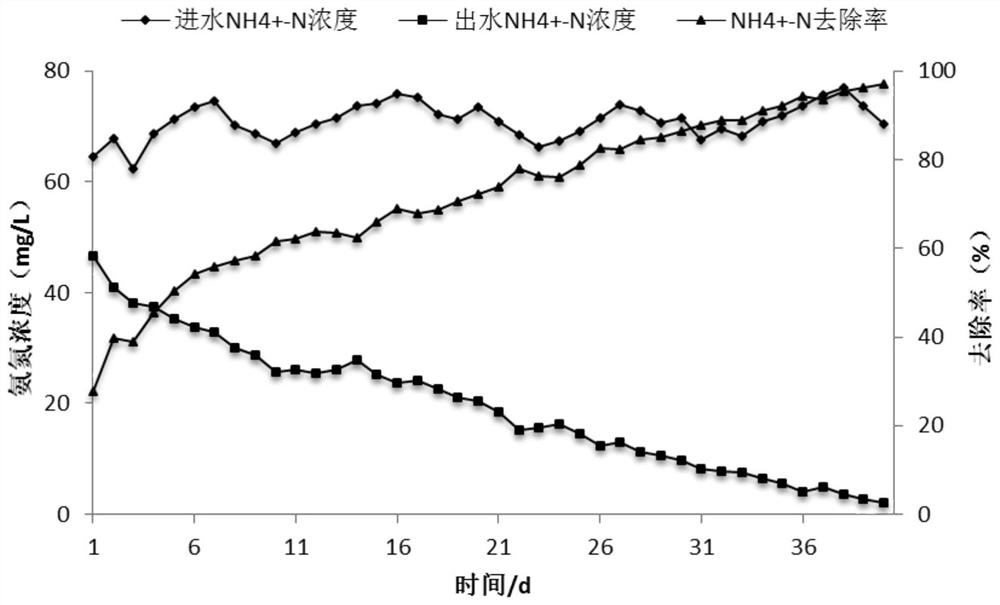

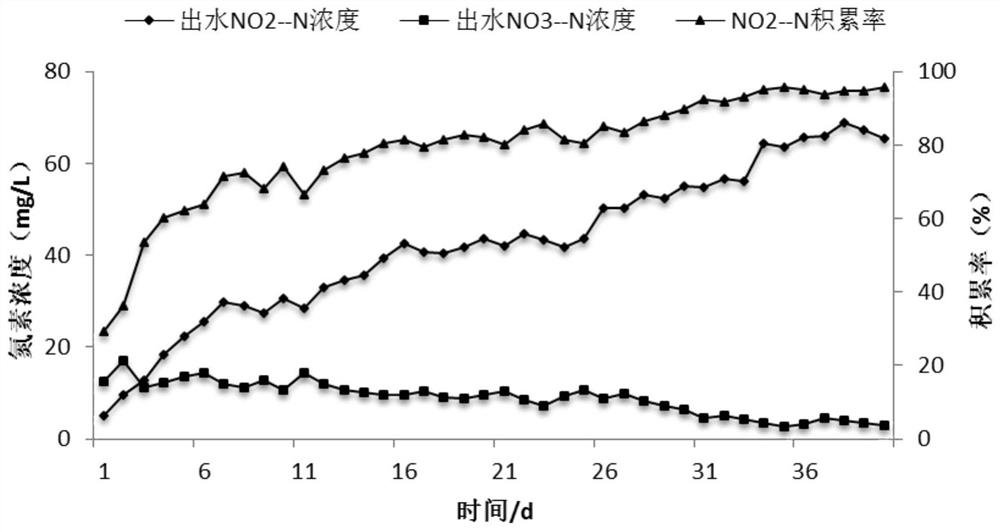

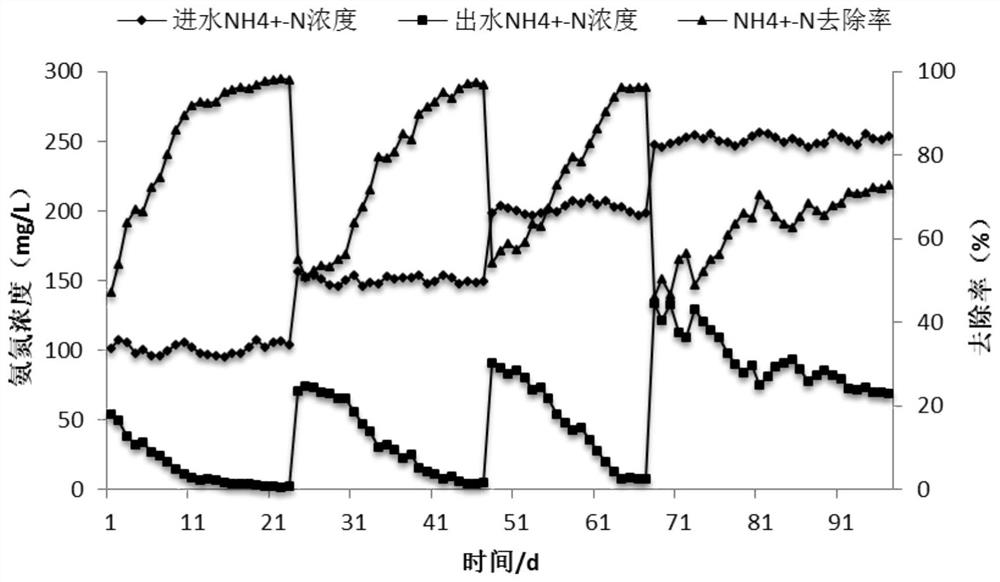

[0024] refer to Figure 1-3 , a kind of SBR partial nitrosation process matching anaerobic ammonia oxidation that the present invention proposes, comprises the following steps,

[0025] S1, Sludge domestication pretreatment: First, let the inoculated sludge settle for 24 hours, and there will be a large amount of floating matter on the upper layer. After removing it, add a certain amount of test water, and then expose it for 48 hours. The main purpose is to use the endogenous respiration of the microorganism itself It can be used to remove the remaining organic matter in the sludge, and finally stand for 24 hours; after standing, it is found that the color of the sludge turns brown, the measured SV value is 32%, and the sludge concentration MLSS is 3800mg / L, which shows that after being stuffed The activity of the sludge treated by exposure and static treatment has been restored to some extent, which meets the requirements for inoculation; the composition of the test water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com