Microalgae medium and method for culturing microalgae to produce hydrogen

A technology for producing hydrogen and culture medium, which is applied in the fields of bioengineering and medicine, can solve the problems of low hydrogen production and hydrogen production rate, and achieve the goal of increasing hydrogen production and hydrogen production rate, increasing hydrogenase activity, and enhancing cellular respiration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

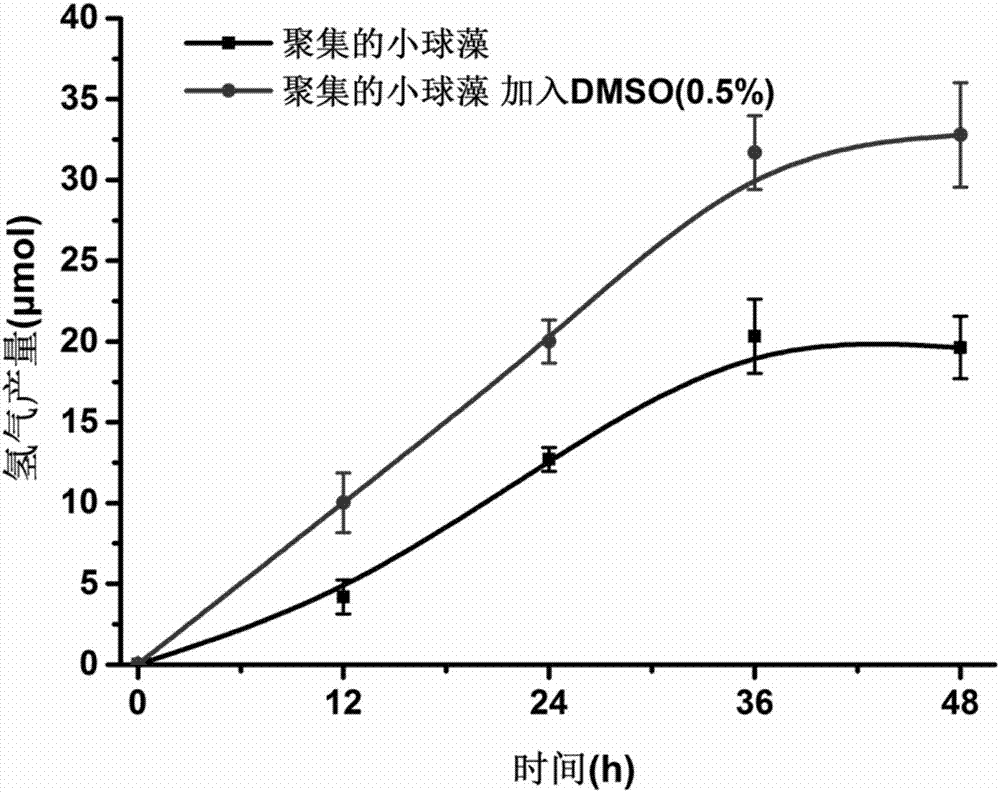

Embodiment 1

[0045] Chlorella cells were cultured to logarithmic phase (cell density 1×10 8cells / mL), adding 1 g / L cationic polyelectrolyte polydimethyldiallylammonium chloride (PDADMAC) to modify the surface of algal cells, so that the algal cells whose surface was originally negatively charged were positively charged. Then, the algal liquid collected by centrifugal washing was evenly mixed with 5 mM sodium silicate solution, and stirred for 30 min to form microalgae aggregates. Then wash and resuspend with TAP medium, and divide into 60mL sealed tubes with 30mL algae solution in each tube, and the above is used as the control group. Add DMSO to the above 30mL algae liquid to make the final concentration 0.5% (volume ratio), as the experimental group. The two groups were at 100μE m -2 the s -1 Exposure to light for 48 hours.

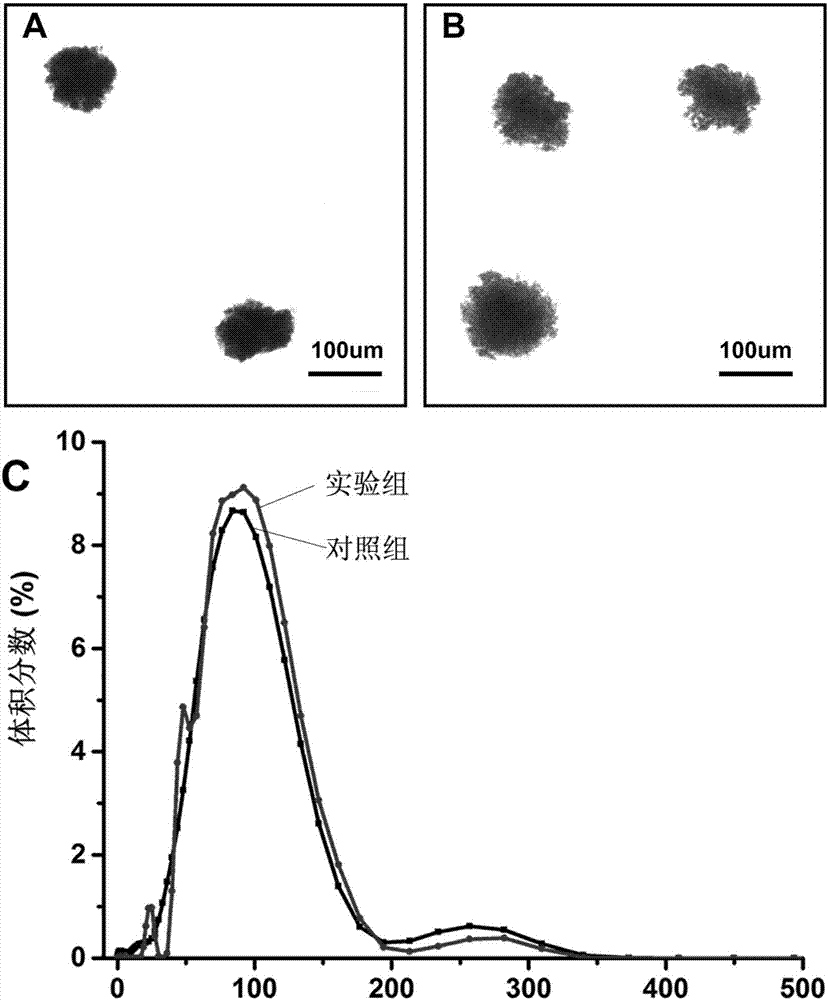

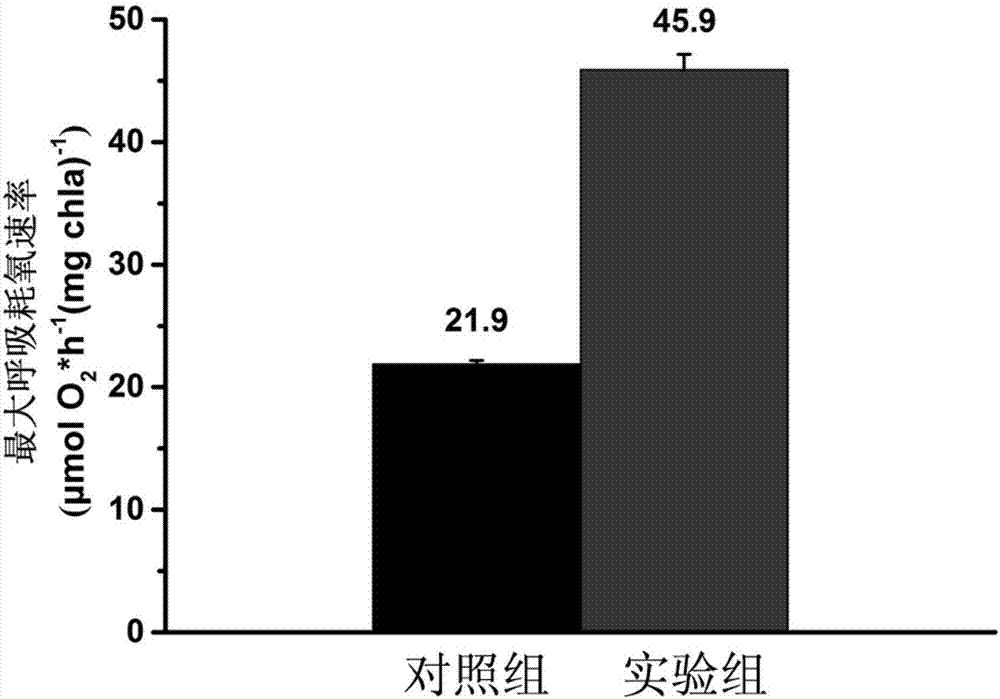

[0046] (1) The aggregated chlorella and the chlorella aggregates added with DMSO were observed under an optical microscope, and the particle size statistical an...

Embodiment 2

[0050] Chlorella cells were cultured to logarithmic phase (cell density 1×10 8 cells / mL), adding 1g / L cationic PDADMAC to modify the surface of the algal cells, so that the algal cells whose surface was originally negatively charged were positively charged. Then, the algal liquid collected by centrifugal washing was evenly mixed with 5 mM sodium silicate solution, and stirred for 30 min to form microalgae aggregates. Then wash and resuspend with TAP medium, and divide into 60mL sealed tubes with 30mL algae solution in each tube, and the above is used as the control group. Then add DMSO to the above 30mL algae liquid, so that the final concentrations are 0.1%, 0.3%, 0.5%, 1%, 2%, 3%, 5% (volume ratio), as the experimental group. respectively at 100μE m -2 the s -1 After irradiating under light for 48 hours, measure the hydrogen accumulation in the headspace of the sealed tube. Each concentration was repeated 5 times.

[0051] The result is as Figure 4 As shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com