A method for gasification dephosphorization and recycling of semi-steel smelting converter final slag

A steel smelting and final slag furnace technology, applied in the field of steelmaking waste reuse, can solve the problems of converter slag reuse rate less than 30%, treatment cost limitation, affecting the application range of converter slag, and achieve less investment and popularization threshold Low, high return effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

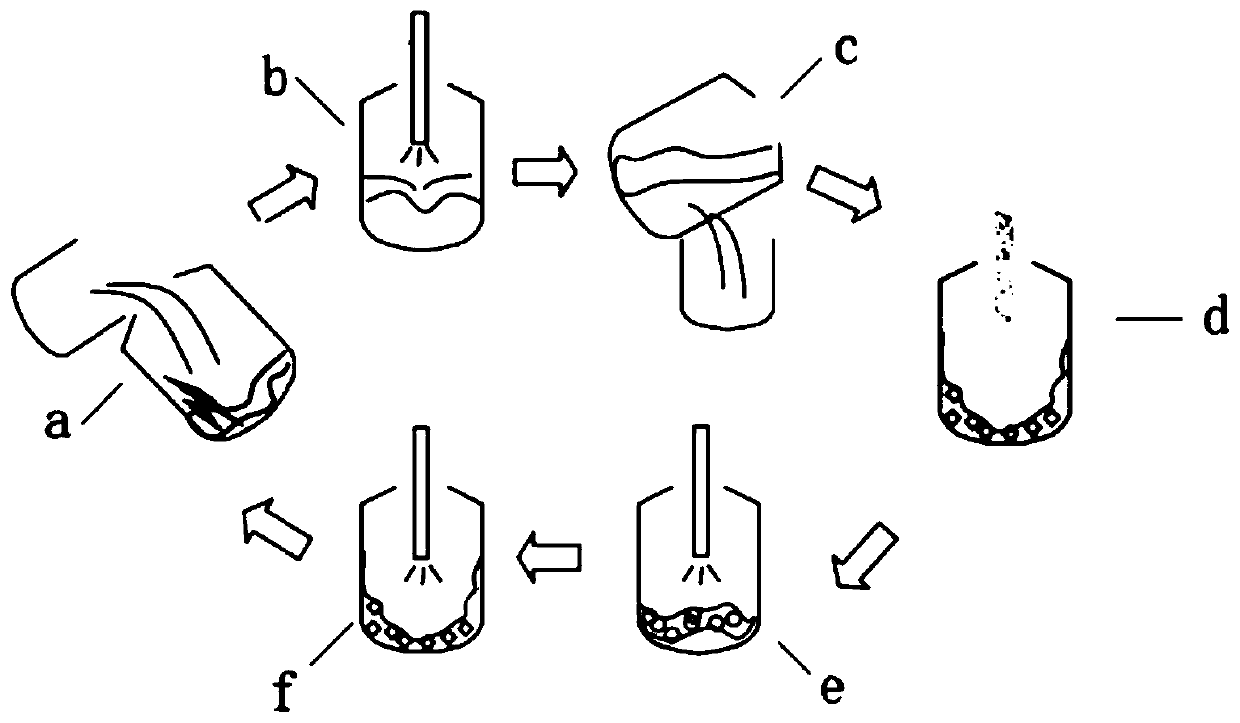

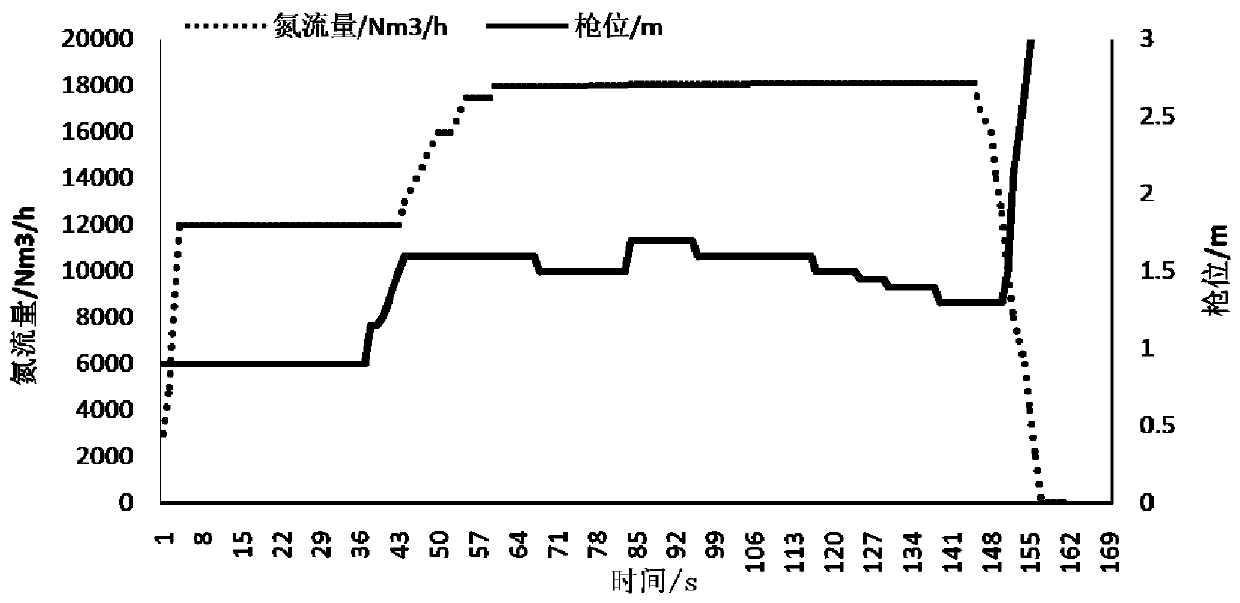

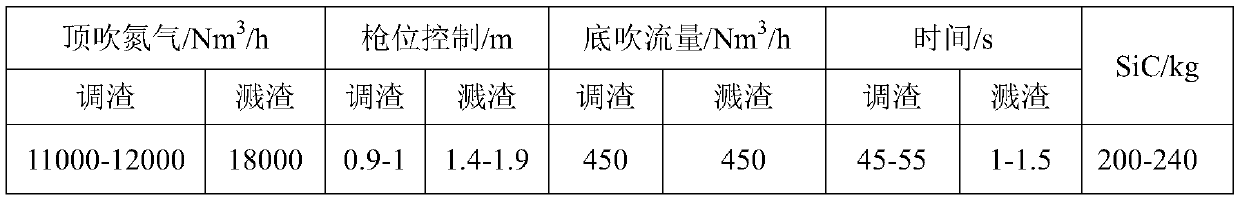

[0034] Specific embodiments of the present invention will be specifically described below with reference to the accompanying drawings, which are part of the patent application for the present invention, and together with the examples of the present invention, illustrate the implementation of the present invention.

[0035] An enterprise adopts the dual combination of "vanadium extraction converter + semi-steel smelting converter" for smelting, and the smelted steel type is

[0036] For HRB400E, the composition of semi-steel after vanadium extraction finishes is shown in Table 1 (mass percentage):

[0037] Table 1 Semi-steel composition

[0038] T / ℃ C / % Si / % Mn / % P / % S / % 1390-1410 3.6-3.9 0.025-0.035 0.03-0.05 0.09-0.1 0.03-0.052

[0039] s1, add semi-steel into the converter with primary slag, such as figure 1Shown in a. In this embodiment, the intermediate converter adopts a 100-ton top-bottom combined blown semi-steel smelting converter.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com