Bottle body transferring device and method

A technology of transfer device and bottle body, applied in the fields of medicine packaging and food, can solve the problem that the filling machine cannot meet the requirements, etc., and achieve the effects of reliable transfer, simple steps and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

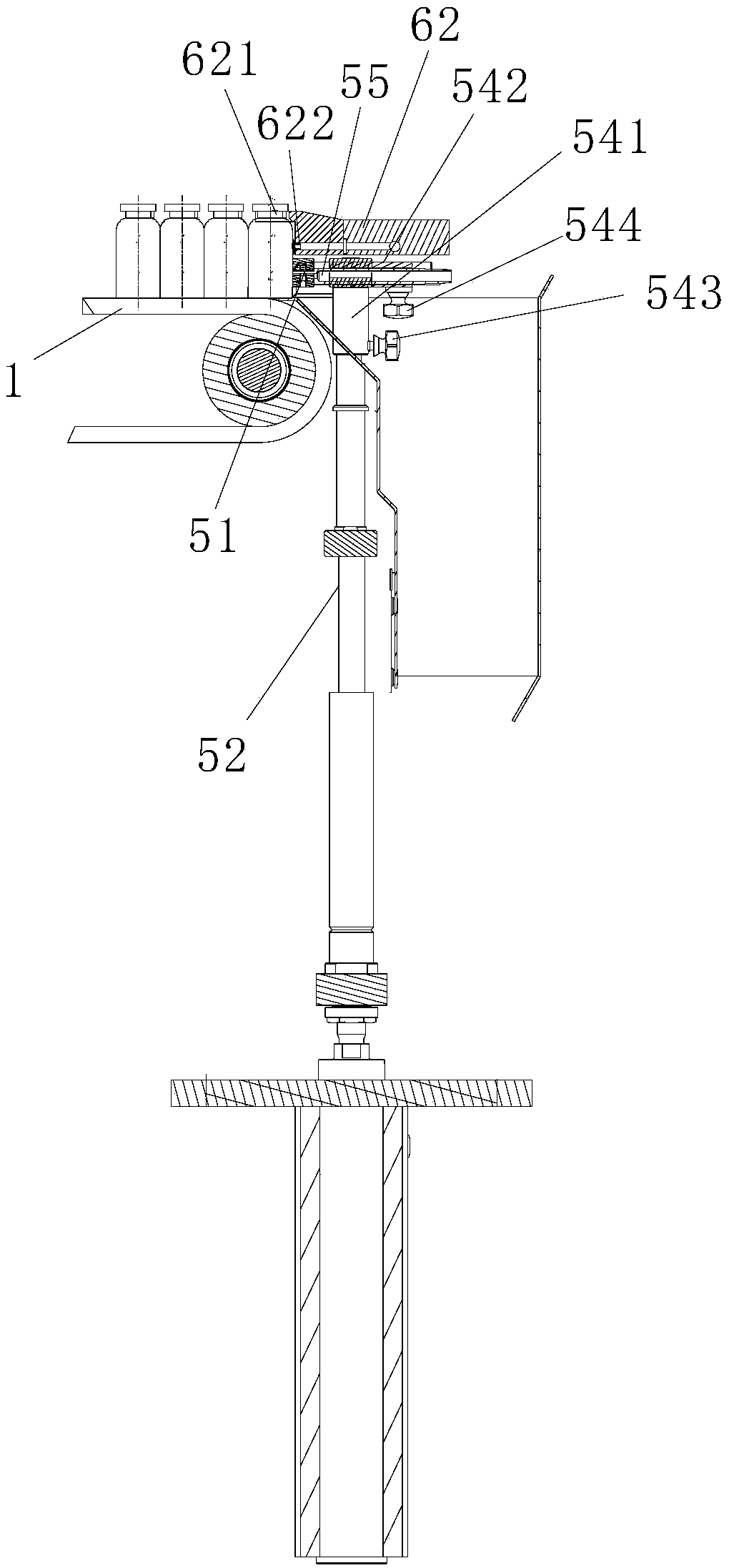

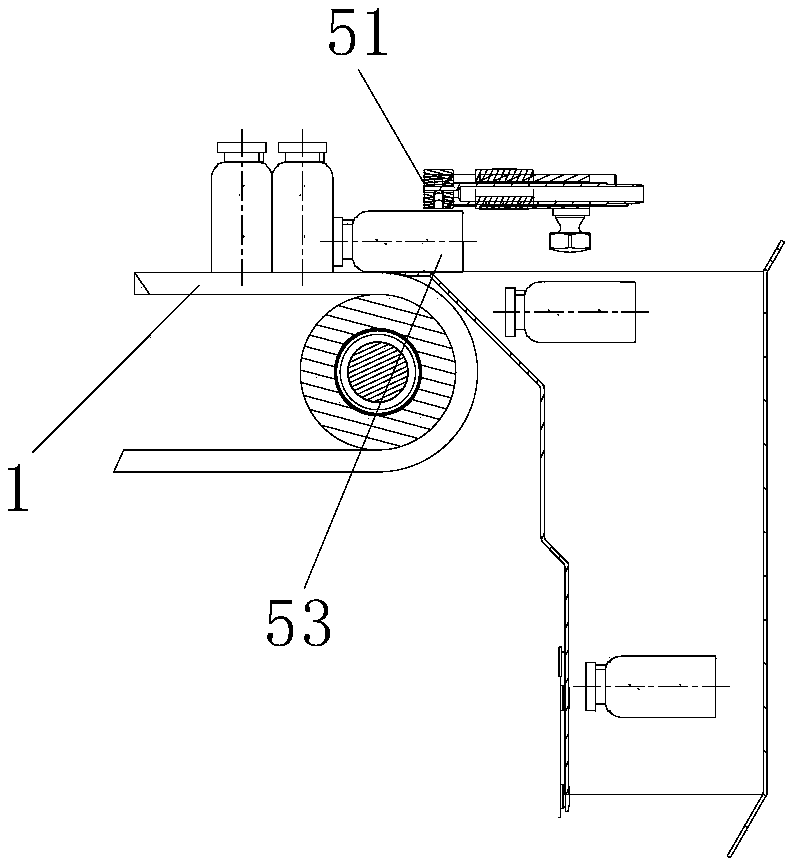

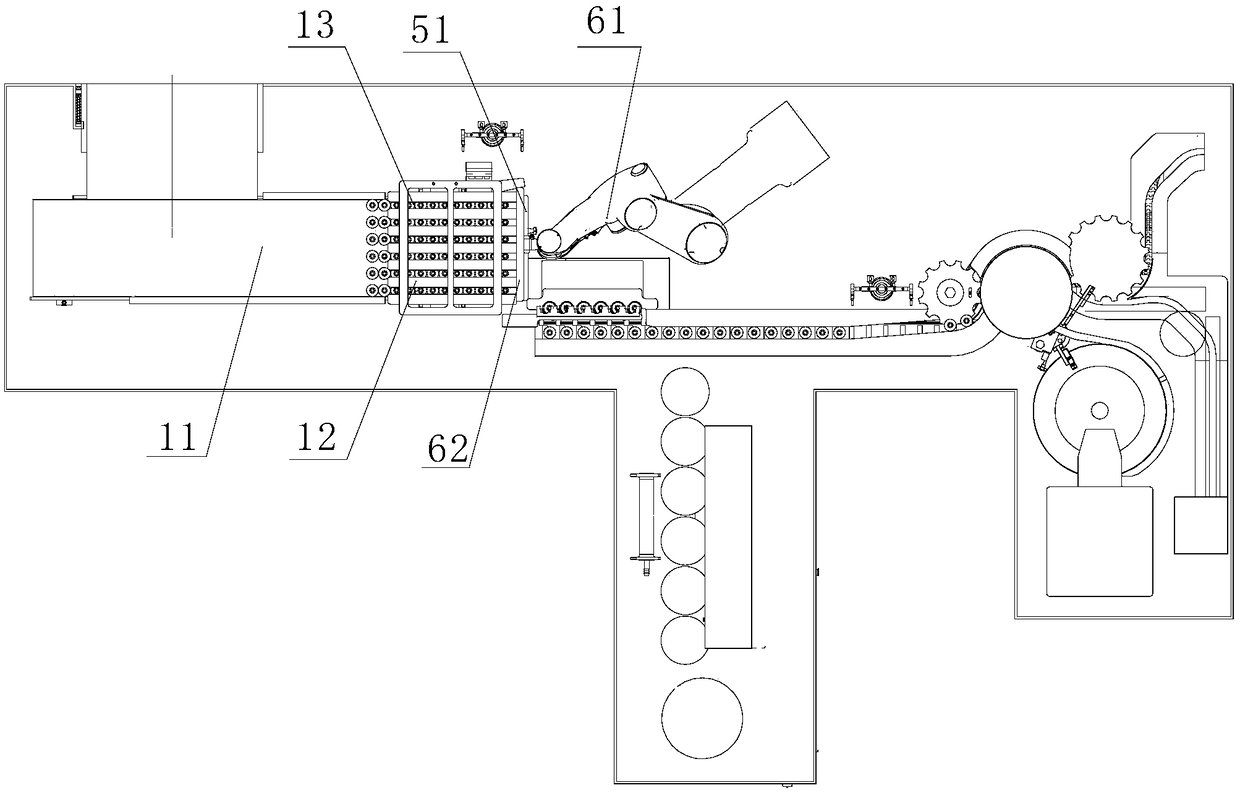

[0028] Figure 1 to Figure 4 An embodiment of the bottle body transfer device of the present invention is shown. The bottle body transfer device of the present embodiment includes a bottle conveying mechanism 1, and also includes a bottle stopper 51 for blocking the bottle conveyed by the bottle conveying mechanism 1. Detect the bottle body detection part 55 with or without bottle body at the bottle stop part 51, and the transfer mechanism 6 for taking out the bottle body blocked by the bottle stop part 51 from above and transferring it to the target position. The bottle stop part 51 is located at On a reciprocating motion mechanism. Wherein, the bottle retainer 51 can be, for example, a bottle retainer or a bottle retainer bar, etc., the bottle detection member 55 can be, for example, an optical fiber detection component, etc. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com