Rubber brick module

A technology for connecting plates and substrates, which is applied to building components, buildings, building structures, etc., can solve the problems of high cost, complicated installation, and long production time, and save time, improve installation efficiency, and save installation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the examples.

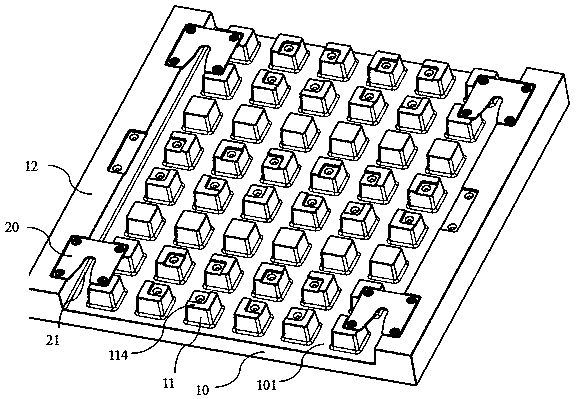

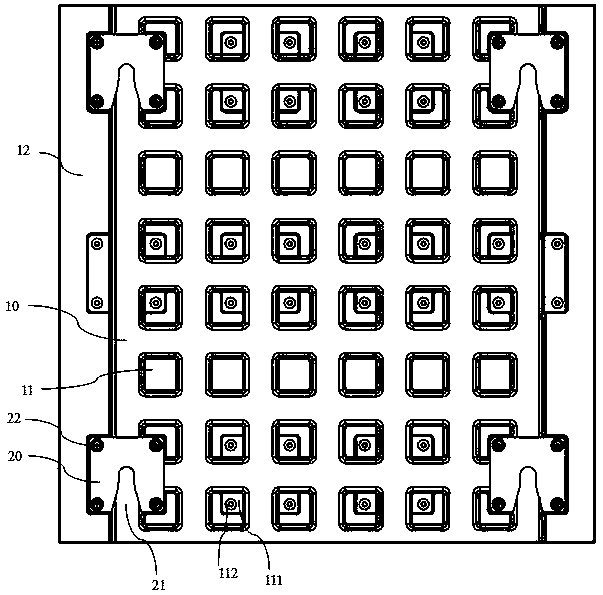

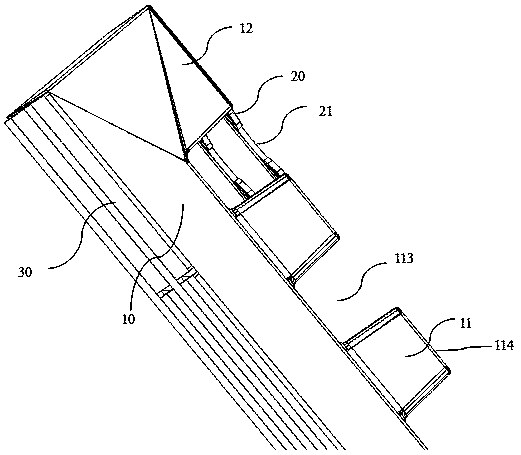

[0034] Please refer to Figure 1 to Figure 4 , the embodiment of the present invention provides a glue brick module for laying on the fixed surface 40, the fixed surface 40 refers to the surface of the building ground, wall or ceiling, especially the ground, wall or ceiling laid on the shooting range surface, so that the built shooting range has good sound insulation, shock absorption and bulletproof effects.

[0035] The adhesive brick module includes a base body 10, the base body 10 is roughly in the shape of a square plate, including a first surface and a second surface 101 opposite to the first surface, wherein the second surface 101 faces the fixing surface 40. The first surface faces the direction of the user.

[0036] Preferably, the base 10 is an elastic body. Preferably, the base 10 is made of rubber or plastic materials. In order to further improve the strength of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com