A Space Bicomponent Orbit Control Engine Based on Two-way Single-Nozzle Centrifugal Injector

A technology of injectors and engines, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of limited working pressure, high temperature of the combustion chamber, discounted engine performance, etc., achieve good consistency and uniformity, and improve Swirl influence, effect of increasing tangential component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

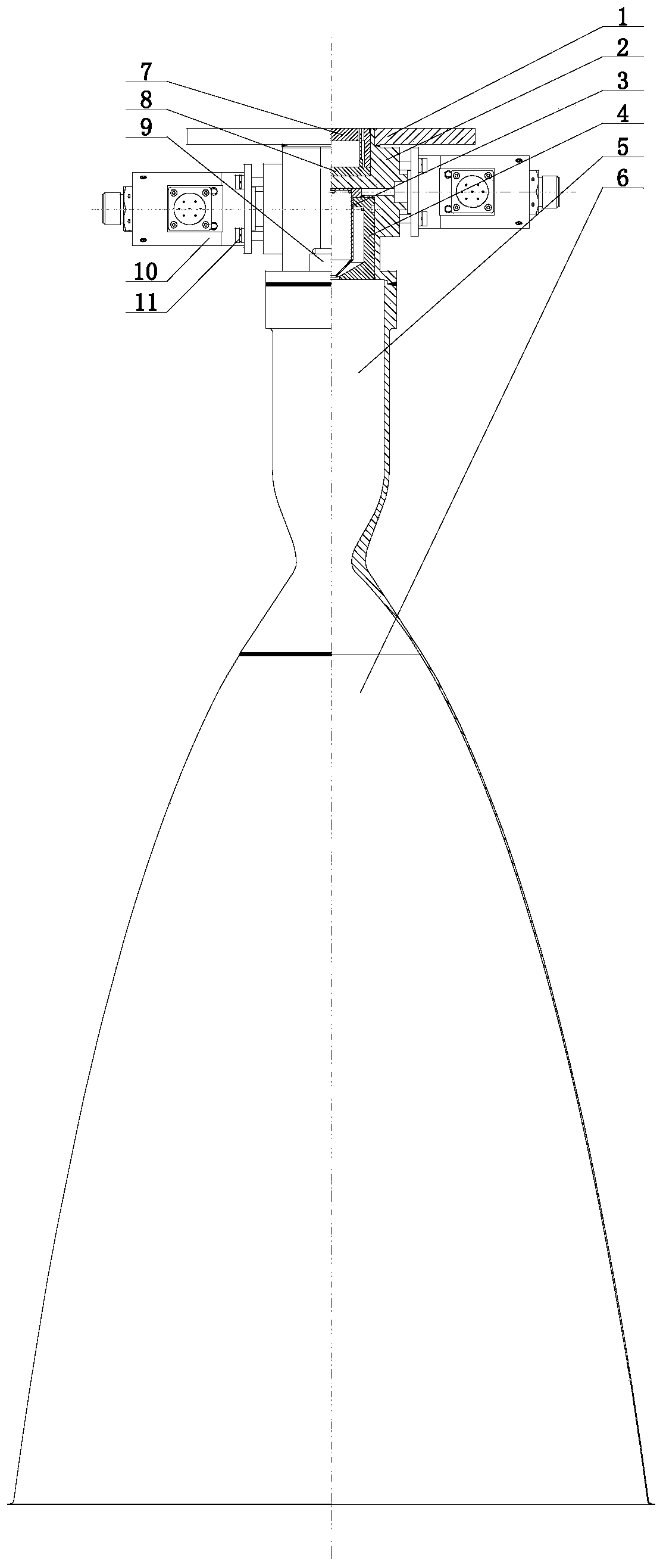

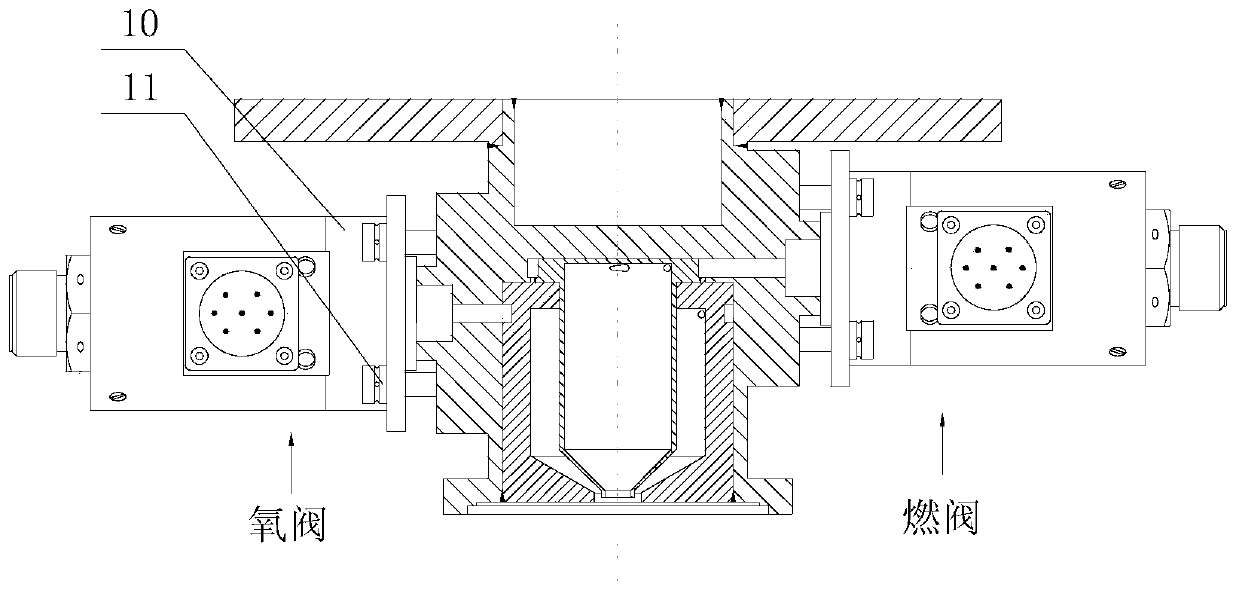

[0038] Such as figure 1 As shown, the present invention provides a space dual-component rail control engine based on a dual-channel single-nozzle centrifugal injector and a molybdenum silicide composite coating thrust chamber, including a mounting plate 1, a main structure 2, an inner nozzle 3, an outer The nozzle 4, the thrust chamber part includes a combustion chamber 5, a nozzle 6, a heating device 7, a cover plate 8, a temperature sensor 9, a control valve 10 and a screw 11;

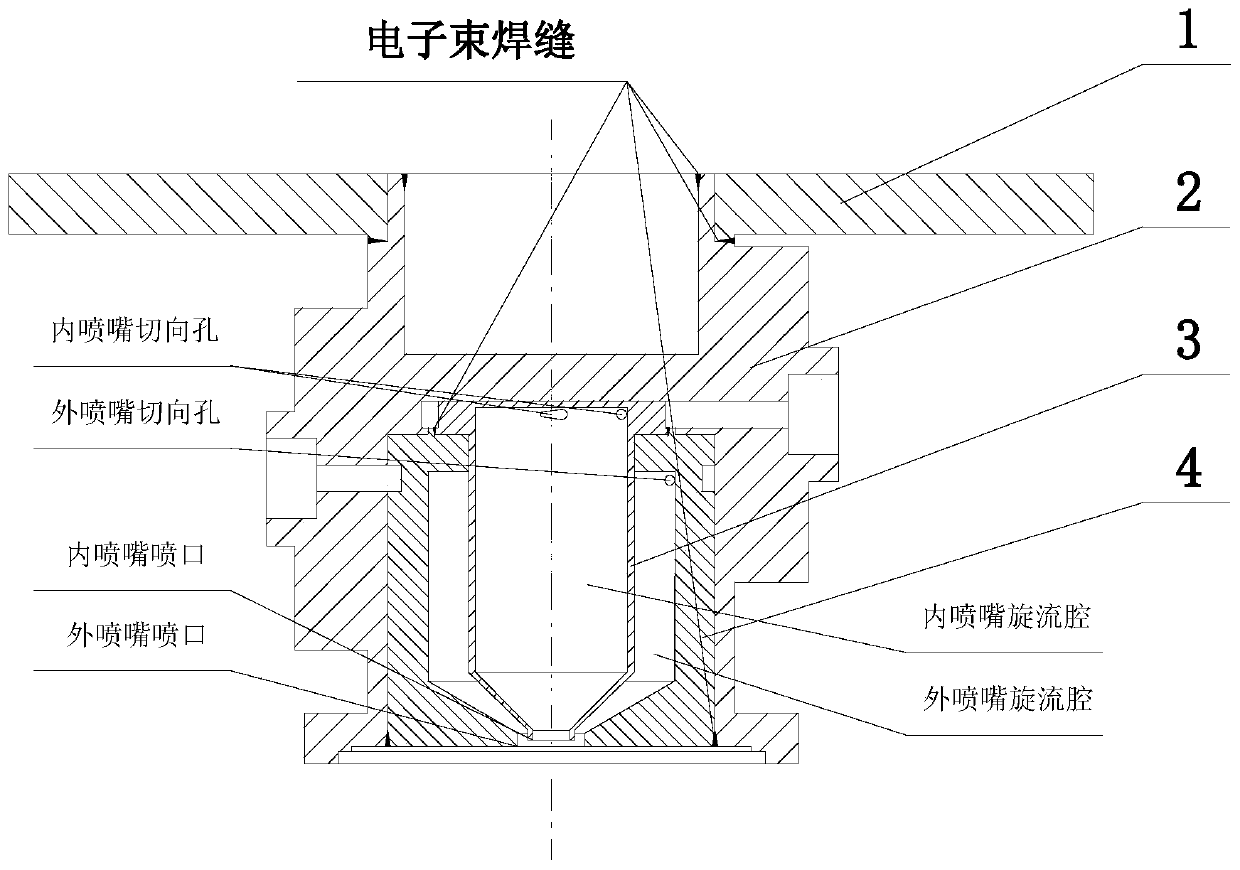

[0039] Such as figure 2As shown, the mounting plate 1 is a hollow circular plate with mounting holes, the top of the main structure 2 is inserted into the central hollow of the mounting plate 1, and is connected and fixed with the mounting plate 1 by electron beam welding; the main structure 2 is the top, There is a cylinder with a central hole at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com