Method for measuring mineralization of shale pore water

A technology of pore water and salinity, which is applied in the direction of measuring devices, by removing certain components, weighing, instruments, etc., can solve the problem of difficulty in detecting the salinity of shale pore water, and achieve convenience, efficiency and accuracy The effect obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

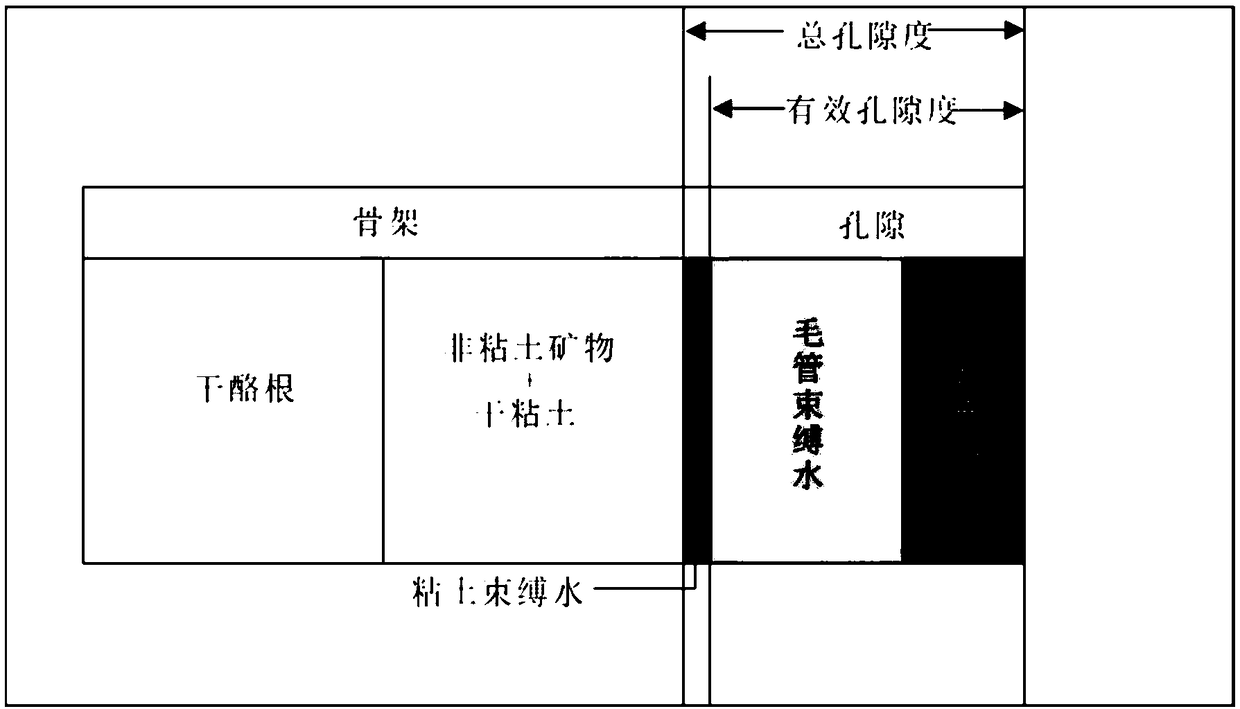

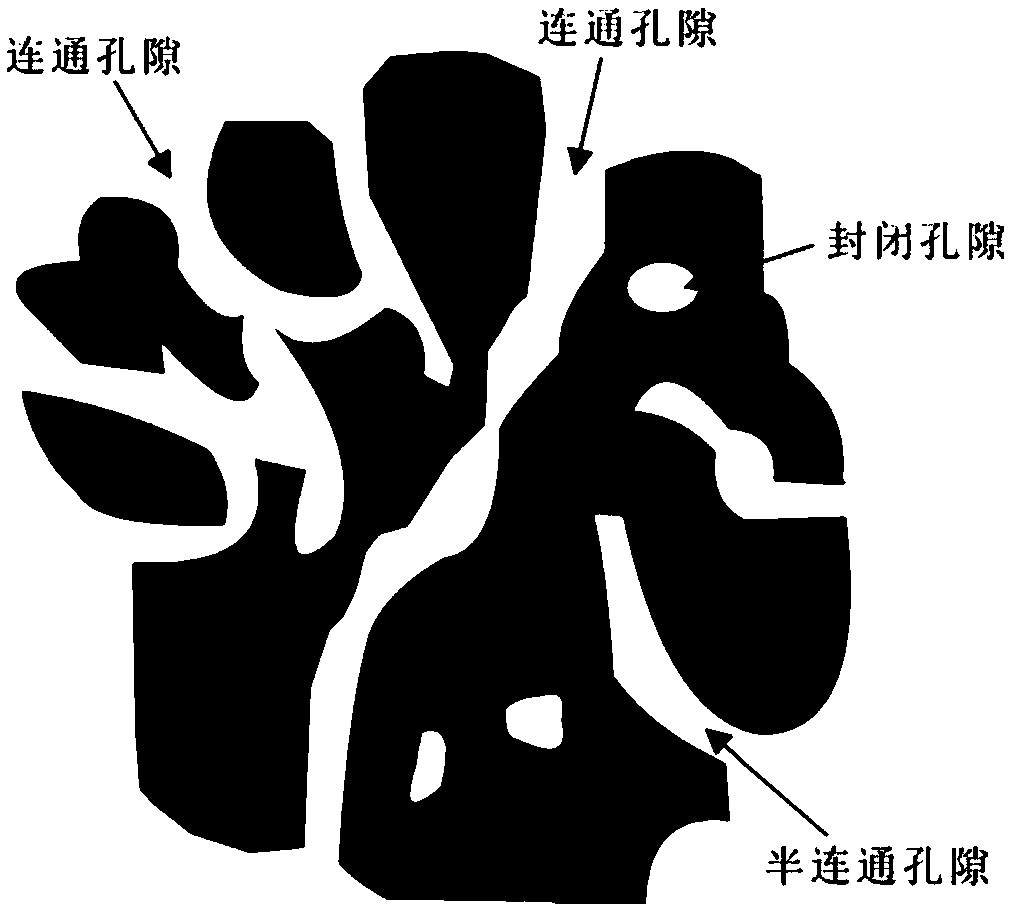

[0046] The present embodiment is a method for measuring the salinity of shale pore water in a corresponding area during shale gas exploitation, and the quality of the pore water of the rock sample is measured by the method of crushing-weighing-drying-weighing; Then, the method of drying-crystallization-redissolving is used to extract the inorganic salts of the shale pore water and test the salinity, so that the salinity of the formation water in the shale pores can be calculated. Since there is no need to measure parameters such as porosity and skeletal density of shale, the calculation accuracy is improved and the test cost is reduced.

[0047] Specific steps are as follows:

[0048] Firstly, shale samples are prepared, the shale samples are fresh shale cores, and 3-5 plug-shaped core samples are prepared for testing.

[0049] The pore water content in the prepared shale sample is then determined, the prepared shale sample is pulverized, and its mass is weighed and recorded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com