Direct drive radar turntable

A turntable and radar technology, applied to antennas, electrical components, antenna supports/installation devices, etc., can solve the problems of reduced accuracy, high maintenance costs, shortened life, etc., to avoid unreliable factors, reduce maintenance costs, and the number of spare parts. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

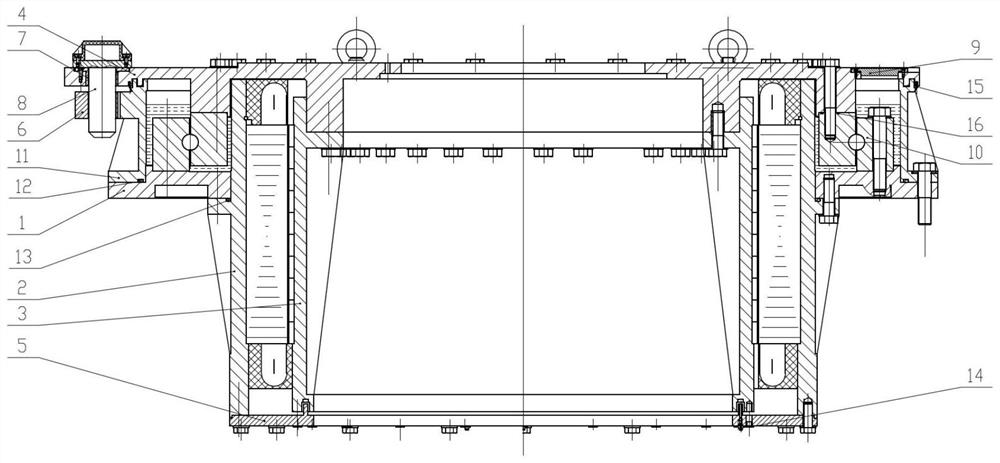

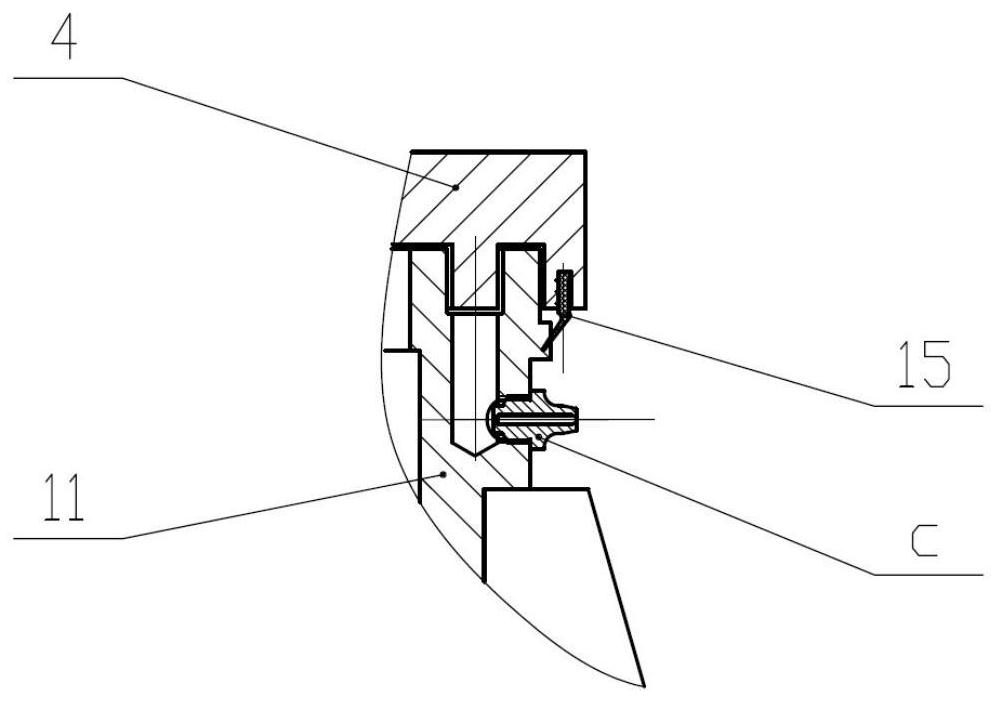

[0015] The direct-drive radar turntable of the present invention includes a base 1, an upper bracket 11, an upper connecting plate 4, a slewing support 10, the slewing support 10 adopts four-point contact ball bearings, a motor stator 2, a motor rotor 3, A lower end cap 5. The parts are combined in turn to form a concentric rotary motion. The motor stator 2, the outer ring of the slewing bearing 10, and the upper bracket 11 are fixed to the base 1, the motor rotor 3 is fixed to the upper connecting plate 4, the upper connecting plate 4 is fixed to the inner ring of the slewing bearing 10, and the lower end cover 5 is fixed to the motor stator 2 on.

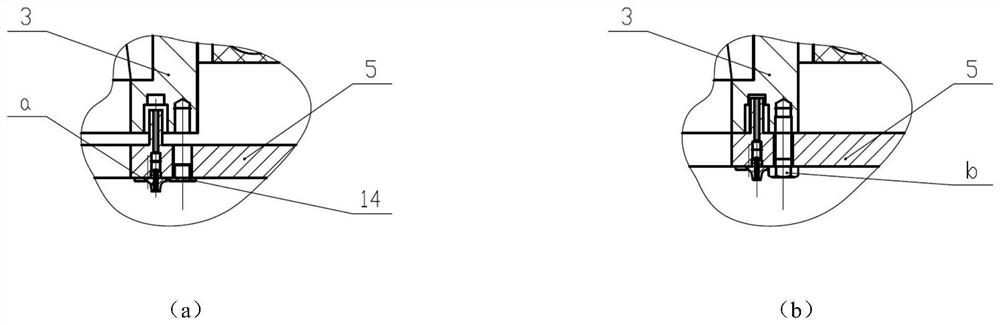

[0016] The base 1 has a positioning step, the lower surface of the upper bracket 11 has grooves, and the axial positioning surface of the motor housing also has grooves, and the first O-ring 12 realizes the sealing cavity of the slewing bearing 10 oil bath lubrication (base 1, upper bracket 11 , The motor stator 2 jointly consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com