Pouring gate valve needle control device for injection mold

An injection mold and control device technology, applied in the field of injection mold valve needle control device, can solve problems such as flow marks, weld marks, and poor molding, achieve flexible and controllable speed and pressure, improve quality, and avoid poor flow marks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

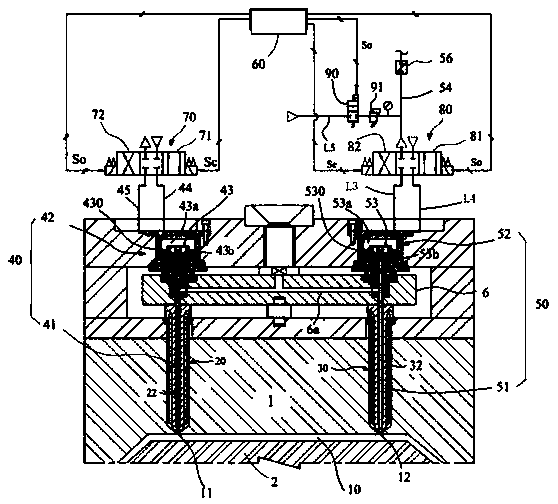

[0048] The second solenoid valve 80 is connected with the downstream side air discharge pipeline 54 corresponding to the third pipeline L3, and the throttle valve 56 is arranged on the downstream side air discharge pipeline 54 to discharge the second solenoid valve 80. Air flow control.

Embodiment 2

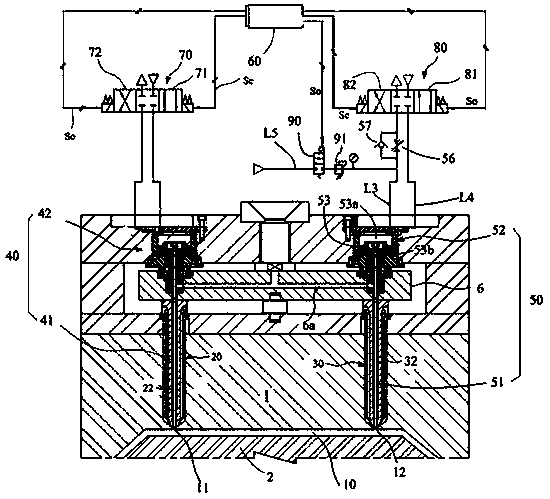

[0050] The throttle valve 56 is arranged on the third pipeline L3, and the third pipeline L3 is provided with a check valve 57 connected in parallel with the throttle valve 56, which passes through one way, so that the supply through the third pipeline L3 The compressed air in the upper cylinder chamber of the third cavity 53a can bypass the throttle valve 56 to ensure the closing speed of the second glue port 12 .

Embodiment 3

[0052] The throttle valve 56 is arranged on the discharge passage L32 of the second solenoid valve 80, and has a simple structure.

[0053] In addition, in order to have a stable back pressure on the pipeline where the throttle valve 56 is located, the auxiliary compressed air pipeline L5 can also be added, and the auxiliary compressed air pipeline L5 is connected to the third pipeline L3 or the downstream air discharge pipeline 54. connection, the compressed air auxiliary pipeline L5 is provided with an auxiliary solenoid valve 90 and a pressure reducing valve 91, the auxiliary solenoid valve 90 is linearly connected with the control part 60, and the control part 60 is used to control the auxiliary solenoid valve 90, by reducing The pressure valve 91 reduces the pressure of the supplementary compressed air to a certain value, maintains a certain pressure back pressure on the pipeline where the throttle valve 56 is located, and makes the action more stable;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com