Lithium ion battery formation method and lithium ion battery

A lithium-ion battery and a formation method technology, applied in the field of lithium-ion battery formation method and lithium-ion battery, can solve problems such as difficulty in infiltration of electrolyte, influence on battery cycle life, stability and self-discharge, safety, and difficulty in film formation. , to achieve the effect of improving low temperature discharge capacity and high temperature rate discharge performance, improving rate discharge performance and cycle performance, and flexible and controllable uniformity and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

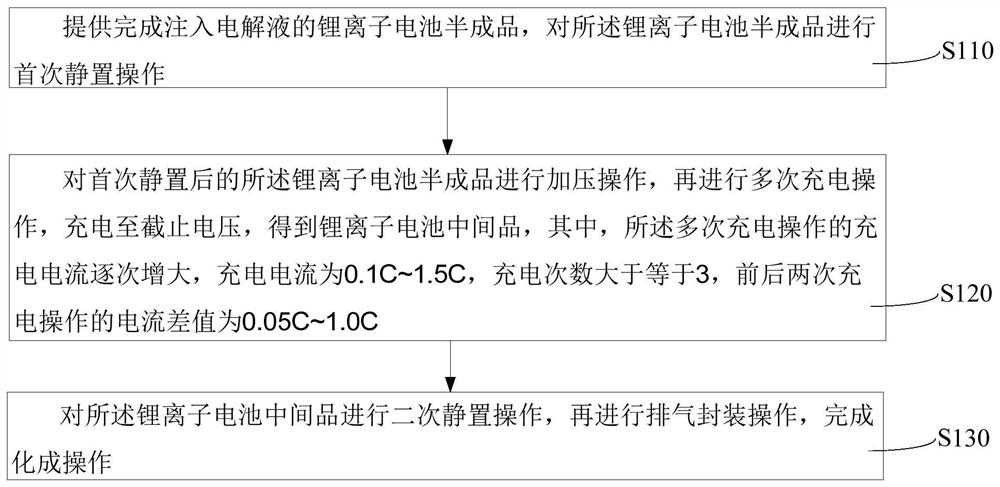

[0028] For an implementation, see figure 1 , a lithium-ion battery formation method, comprising the following steps:

[0029] S110. Provide a semi-finished lithium ion battery that has been injected with electrolyte, and perform a first static operation on the semi-finished lithium ion battery.

[0030] It should be noted that the preparation process of lithium-ion batteries is generally to obtain the positive electrode sheet and the negative electrode sheet by coating the positive electrode slurry and the negative electrode slurry respectively, and then assemble the obtained positive electrode sheet, negative electrode sheet and separator to form a core. , put the pole core into the aluminum-plastic film, and inject the electrolyte to obtain a semi-finished lithium-ion battery. Due to the uneven infiltration of the electrolyte, it will affect the formation of the subsequent SEI film, resulting in difficulty in film formation, and the forming effect of the SEI film will be dir...

Embodiment 1

[0051] S111. Provide a lithium-ion battery semi-finished product that has been injected with electrolyte, perform a pre-sealing operation on the lithium-ion battery semi-finished product, seal the opening of the air bag of the lithium-ion battery semi-finished product, and then conduct a first static test on the lithium-ion battery semi-finished product. Set aside operation, stand still for 10h, and control the temperature of the first standstill to be 43°C.

[0052] S121. Place the semi-finished lithium-ion battery after the first rest in the splint, pressurize the semi-finished lithium-ion battery after the first rest, and control the pressure to 1.15Mpa, and then perform the first charging operation, 0.4C constant current charging for 5 minutes, the charging state of charge is 3.5% SOC, the temperature of the first charging operation is controlled to 55°C, and the second charging operation is performed on the semi-finished lithium-ion battery after the first charging, 0.45C ...

Embodiment 2

[0055] S112. Provide a lithium-ion battery semi-finished product that has been injected with electrolyte, perform a pre-sealing operation on the lithium-ion battery semi-finished product, seal the opening of the air bag of the lithium-ion battery semi-finished product, and then conduct a first static test on the lithium-ion battery semi-finished product. Set aside operation, stand still for 12 hours, and control the temperature of the first standstill to be 45°C.

[0056] S122. Place the semi-finished lithium-ion battery after the first rest in the splint, pressurize the semi-finished lithium-ion battery after the first rest, control the pressurized pressure to 1.2Mpa, and then perform the first charging operation, 0.4C constant current charging for 5 minutes, the charging state of charge is 3.5% SOC, the temperature of the first charging operation is controlled at 60°C, and the second charging operation is performed on the semi-finished lithium-ion battery after the first char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com