Lock cylinder installing structure

A technology of installation structure and lock cylinder, which is used in architectural locks, building structures, and non-mechanical transmission-operated locks, etc., which can solve the problems of easy wear, waste of resources, and inability to use the device normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

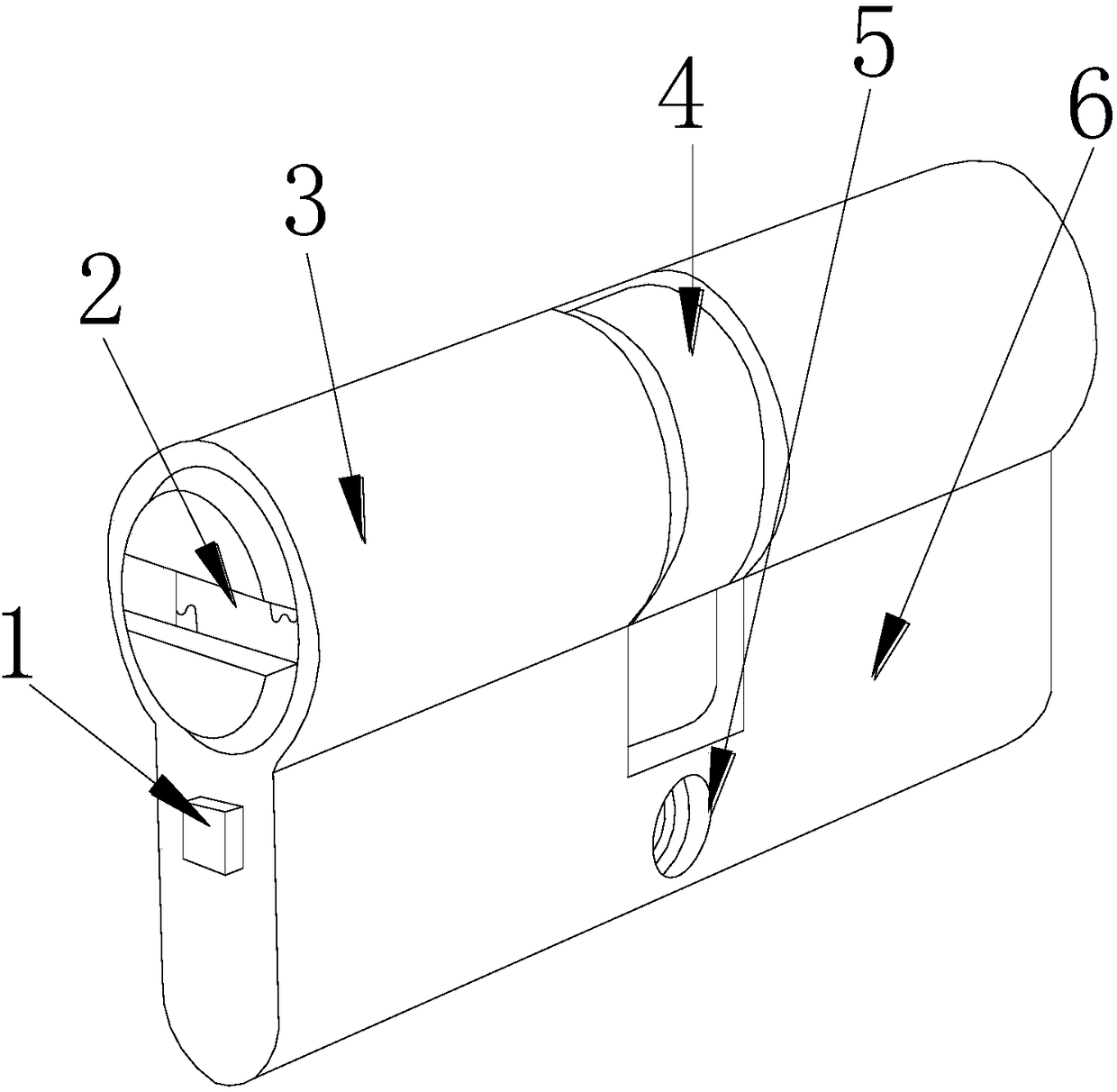

[0028] see Figure 1-Figure 5 , the present invention provides the installation structure of lock core, and its structure comprises lubricating mechanism 1, key socket 2, lock cylinder 3, lock cylinder 4, installation hole 5, fixed base 6, and described key socket 2 is arranged on lock cylinder 3 At the front end, the lock cylinder 3 and the key socket 2 are an integrated structure;

[0029] The lock cylinder 3 is provided with a lock cylinder 4, the lock cylinder 4 and the lock cylinder 3 adopt a clearance fit, the bottom of the lock cylinder 3 is provided with a fixed base 6, and the fixed base 6 and the lock cylinder 3 As an integrated structure, the fixed base 6 is provided with a mounting hole 5, and the described mounting hole 5 and the fixed base 6 are an integrated structure

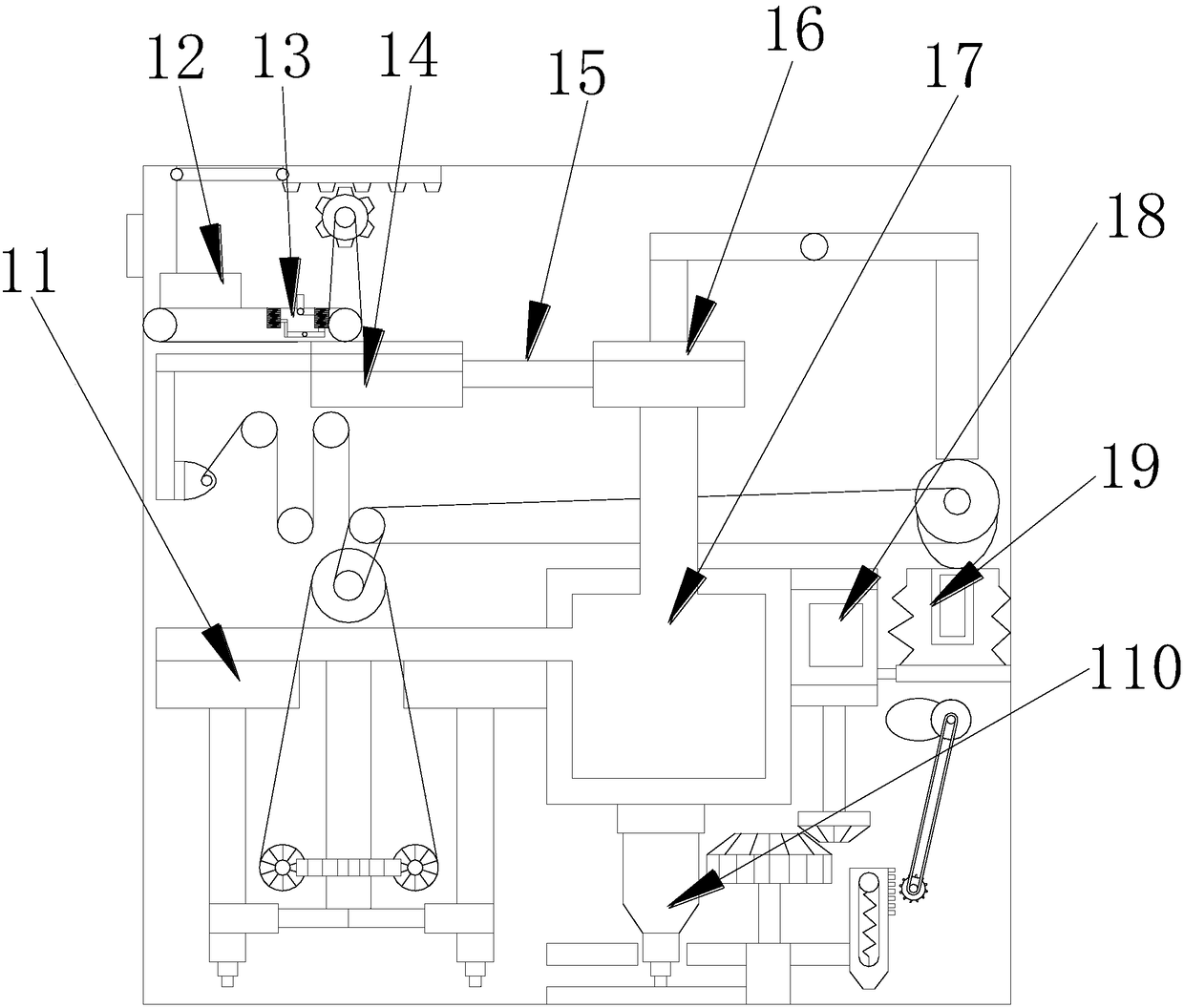

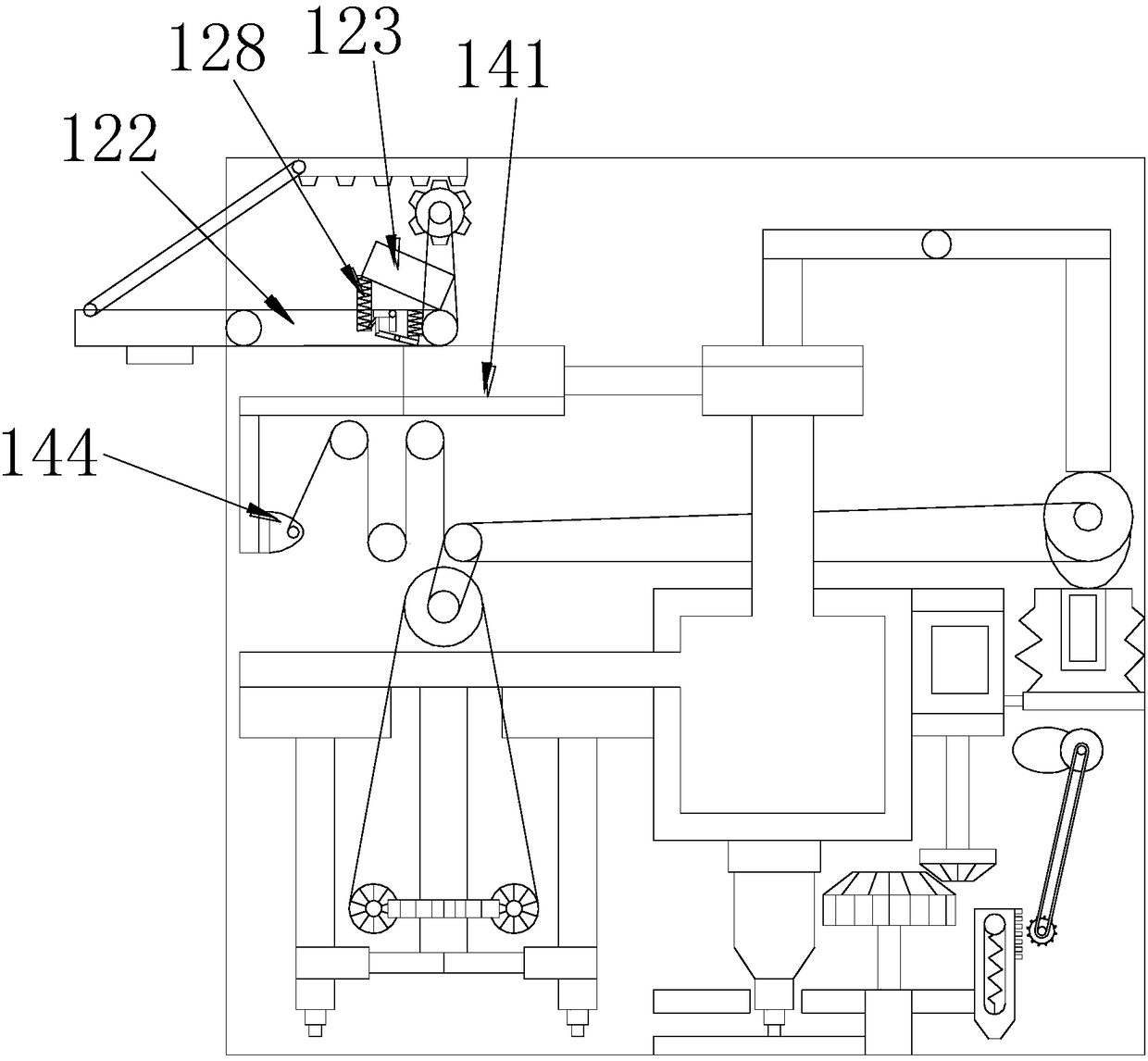

[0030] The lubricating mechanism 1 is arranged at the bottom of the front end of the lock cylinder 3, and the lock cylinder 3 and the lubricating mechanism 1 adopt clearance fit. , a pulley dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com