Fourth-axis rotary indexing processing device for special processing center of valve body

A processing center and processing device technology, applied in positioning devices, feeding devices, metal processing, etc., can solve problems such as lack of valve body clamping, and achieve the effects of reducing manpower, precise loading and locking, and avoiding processing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

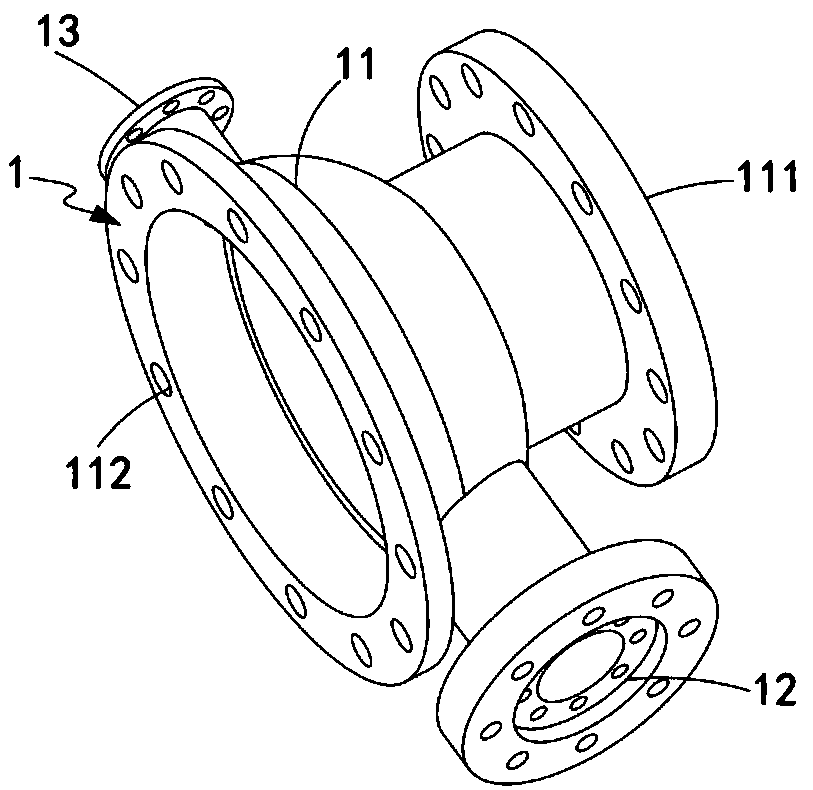

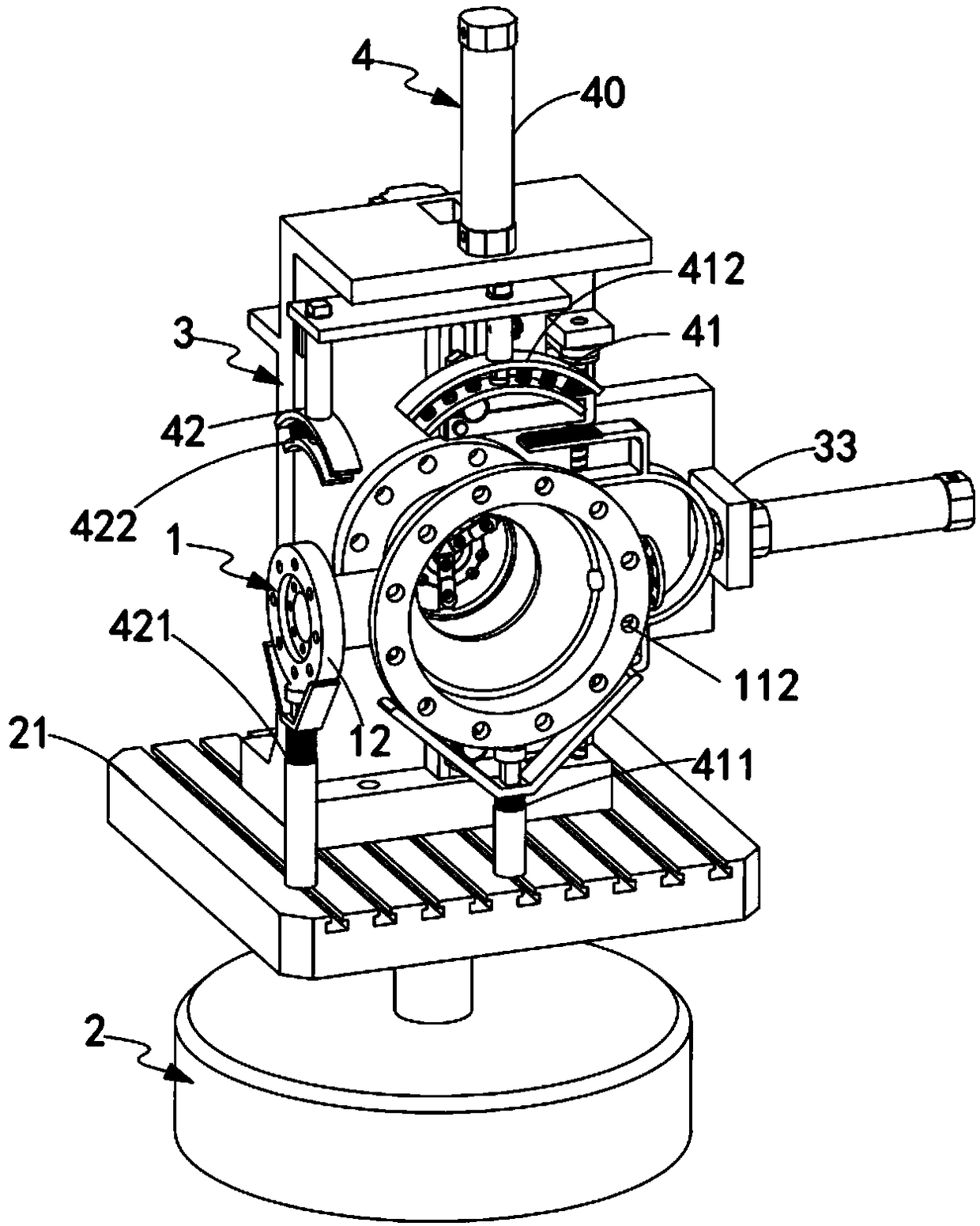

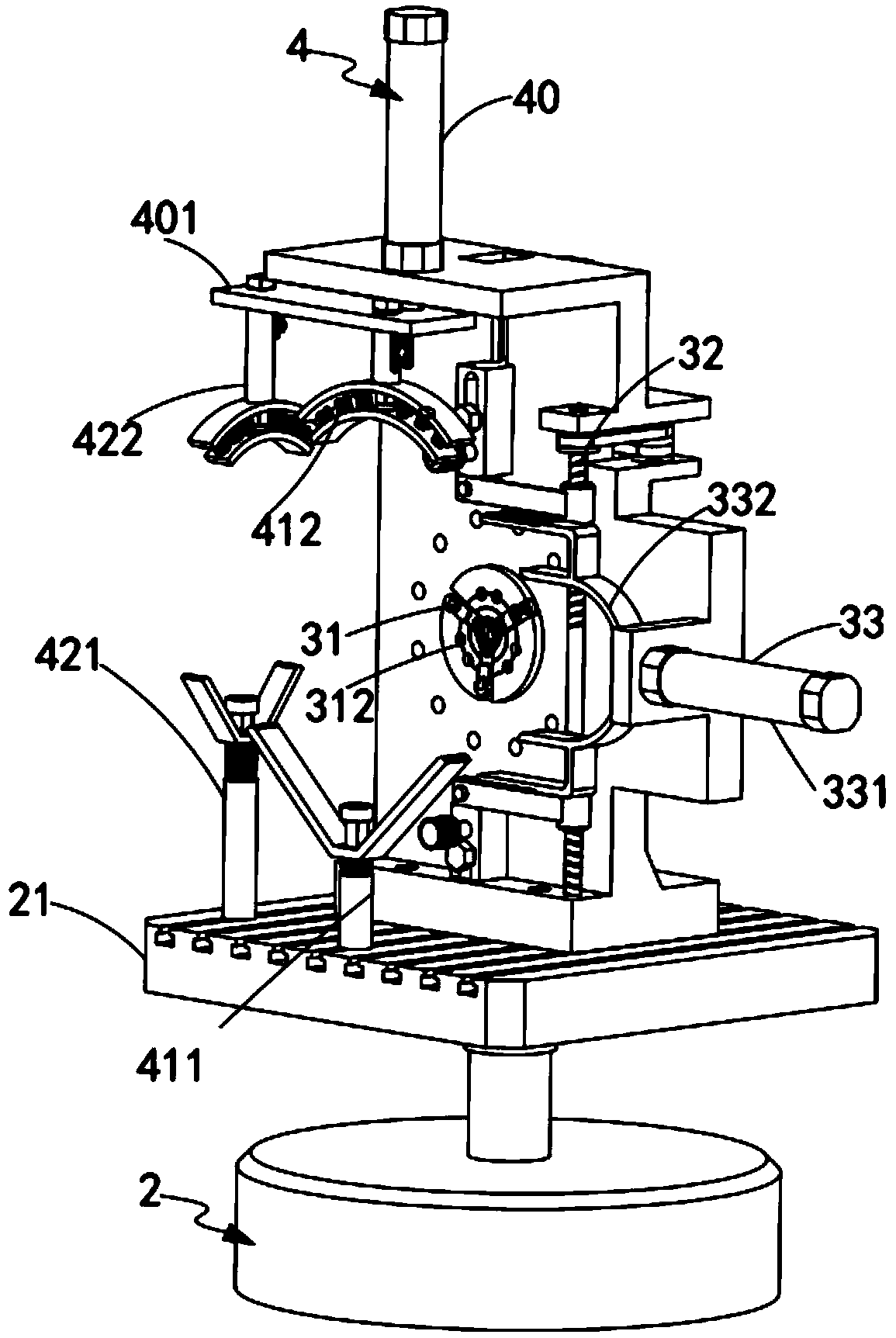

[0072] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a fourth-axis rotary indexing processing device of a valve body special machining center is used for processing a valve body 1. The valve body 1 includes a main body 11 and a first interface end 12 and a second interface arranged perpendicularly to the main body 11. Terminal 13, the first interface terminal 12 and the second interface terminal 13 are respectively arranged on both sides of the main body 11, and the two ends of the main body 11 are respectively the first port 111 and the second port 112, and the device includes:

[0073] A rotating electrical machine 2, a mounting base 21 is installed on the rotating shaft of the rotating electrical machine 2;

[0074] Install the vertical board 3, the installation vertical board 3 is vertically installed on the installation base 21, the first port 111 of the valve body 1 is attached to the installation vertical board 3, and the valve body 1 is fixed on th...

Embodiment approach

[0105] Such as Figure 10 As shown, as a preferred implementation manner, the second support unit 421 includes:

[0106] The second support rod 4211, the second support rod 4211 is arranged at the lower end of the first interface end 12 in the vertical direction, which supports the first interface end 12;

[0107] The second V-shaped clamping plate 4212, the second V-shaped clamping plate 4212 is slidably disposed on the second supporting push rod 4211, and is set in conflict with the edge of the first interface end 12; and

[0108] The second elastic member 4213 , the second elastic member 4213 is sheathed on the second support rod 4211 , and is disposed between the second support rod 4211 and the second V-shaped clamping plate 4212 in conflict.

[0109] Such as Figure 11 , Figure 12 , Figure 16 and Figure 17 As shown, further, the correction unit 421 includes:

[0110] The second arc-shaped top fork 4221, the second arc-shaped top fork 4221 is vertically fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com