Curved profile pultrusion production traction device and method

A technology of pulling equipment and profiles, which is used in the field of pulling equipment for pultrusion production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

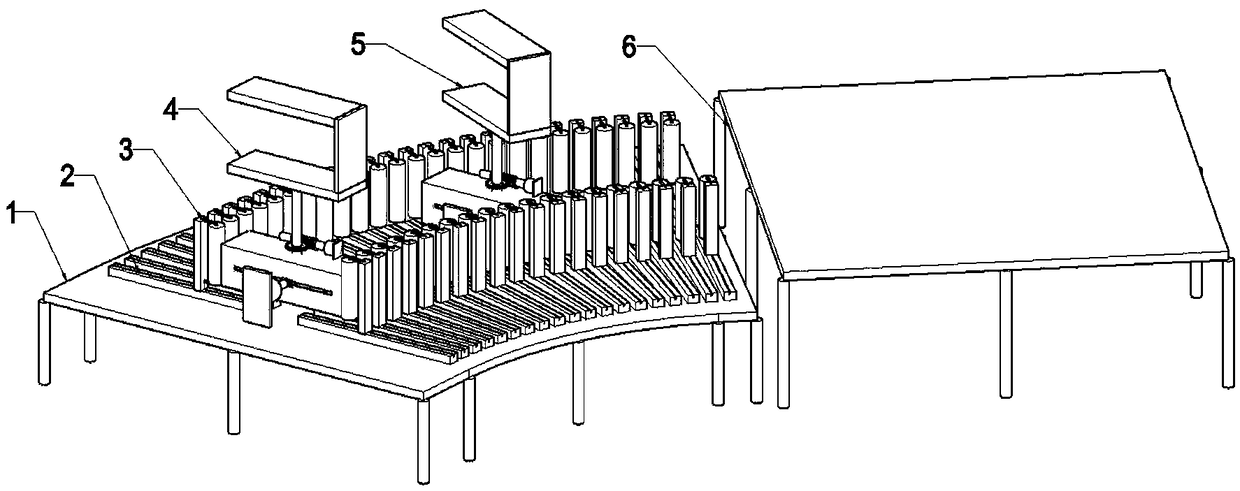

[0022] A kind of pulling equipment for curved profile pultrusion production, such as figure 1 As shown, the traction equipment is composed of a rack platform 1, a slide rail 2, a roller 3, a first traction part 4, a second traction part 5 and a placement platform 6, and the slide rail 2 is installed on the rack platform 1 in a fan-shaped distribution. The rollers 3 are installed on the slide rail 2, arranged along a circular curve to form a track, and limit the movement direction of the traction part. The roller 3 can reciprocate and linearly move along the slide rail 2 to adjust the radius of the circular curve track. The first traction part 4 is located in the curing At the exit of the mold, both the first traction part 4 and the second traction part 5 move along the track formed by the rollers 3, and a placement platform 6 is provided at the end of the movement for placing the completed profiles.

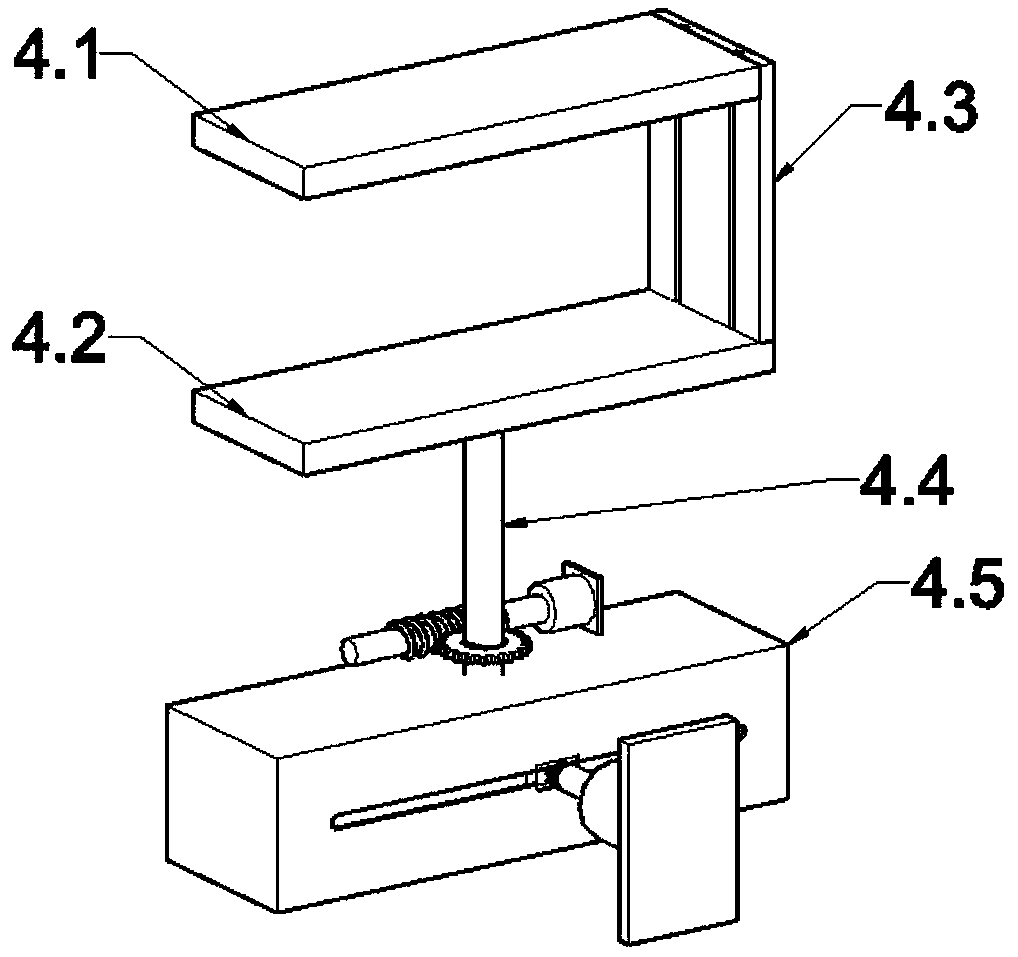

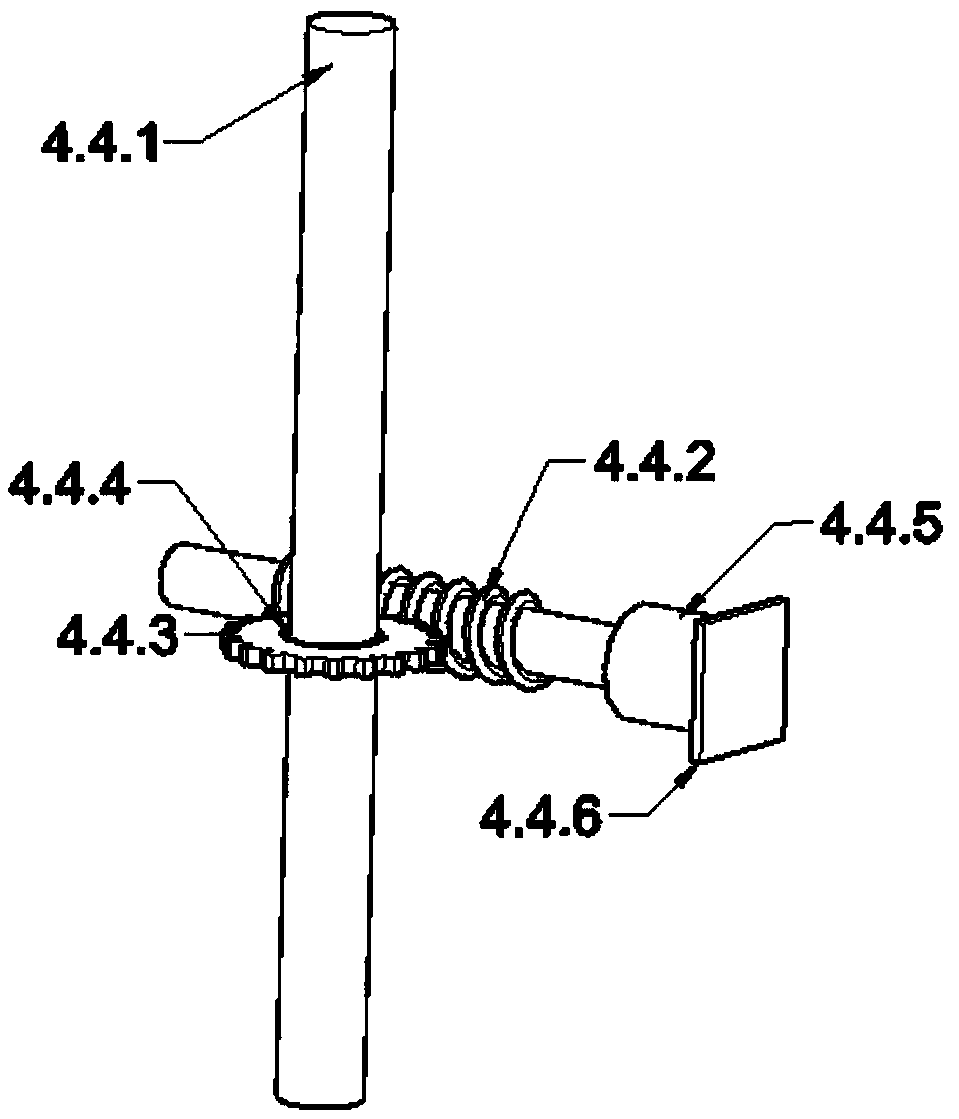

[0023] The first traction part 4 and the second traction part 5 are similar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com