Controller for reducing energy consumption of negative pressure system and control method thereof

A controller and negative pressure technology, applied in the field of automobile negative pressure brake system and negative pressure system control, can solve the problems of large energy consumption of negative pressure system, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

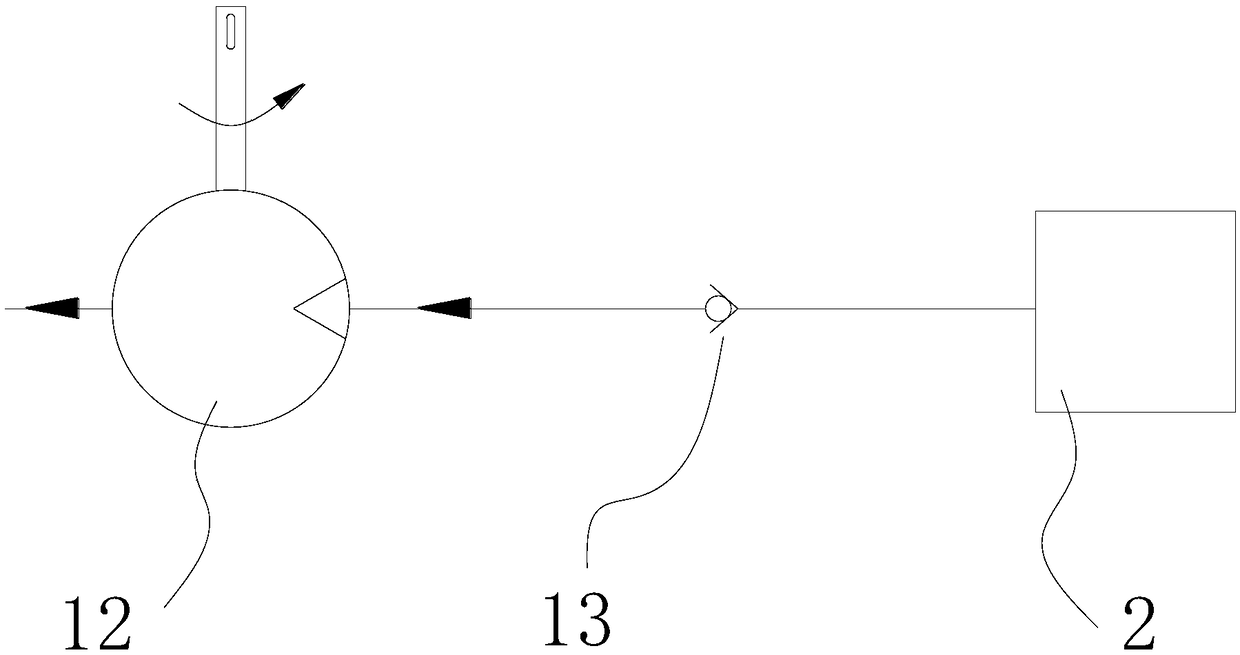

Embodiment 1

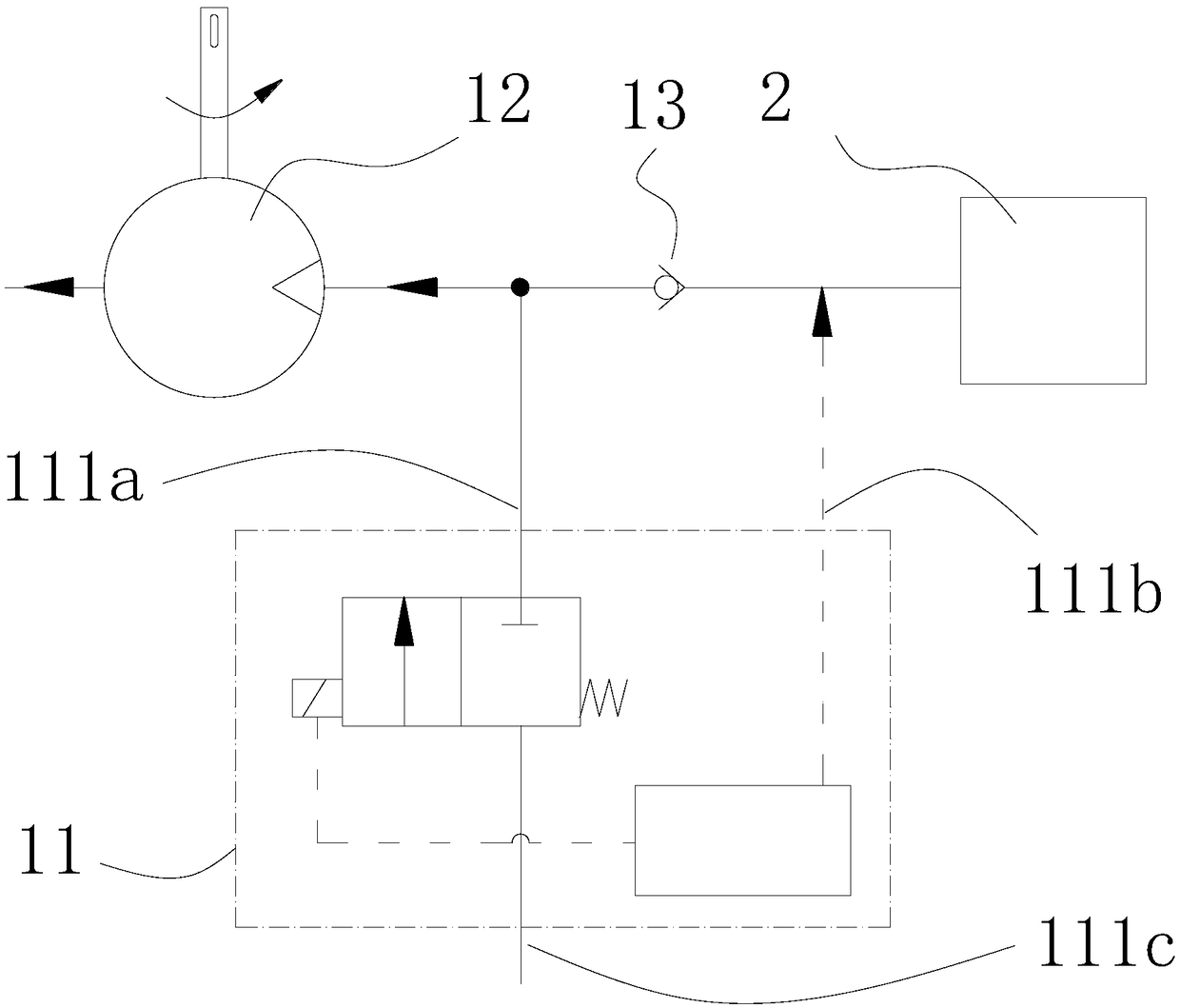

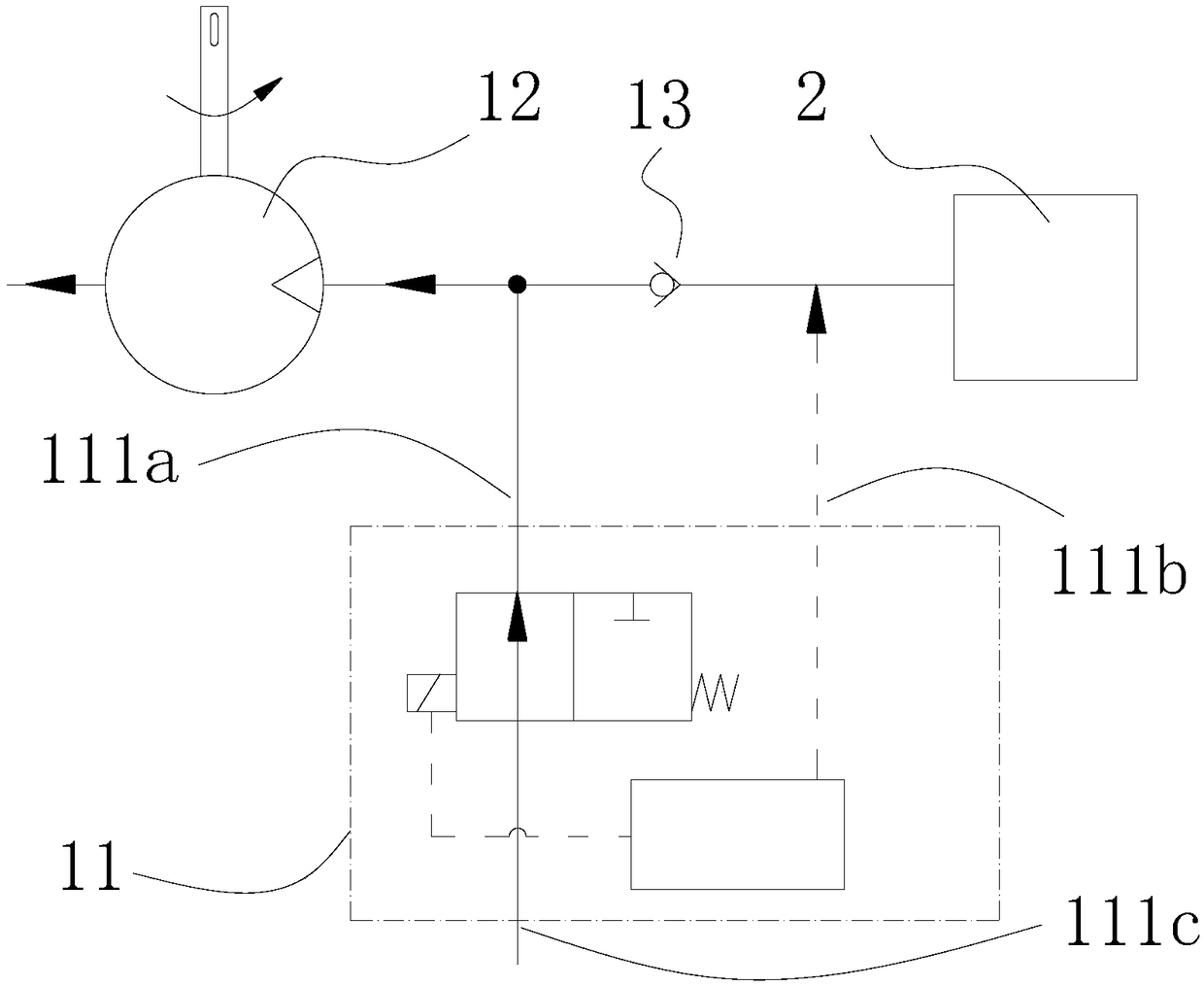

[0075] Such as figure 2 with image 3 As shown, the controller 11 includes an electric valve, a control unit and a pressure sensor. The electric valve has two openings respectively connected to the air outlet 111a and the air inlet 111c. The electric valve is controlled by the control unit and can switch the air outlet 111a and the air inlet. Port 111c is connected and disconnected; further, in order to maintain the safety of the negative pressure system, when the electric valve does not receive a signal or is powered off, the gas outlet 111a and the inlet 111c are in a disconnected state, and the negative pressure pump 12 The negative pressure consumer 2 can be sucked continuously. The air outlet 111 a is connected to the side of the one-way valve facing the negative pressure pump 12 through an air path, wherein the side of the one-way valve facing the negative pressure pump 12 includes a one-way valve, a pipeline and the negative pressure pump 12 . The air inlet 111c lead...

Embodiment 2

[0080] In Embodiment 1, the controller 11 needs to use a pressure sensor to detect the pressure value in the negative pressure consumer 2 through an electrical connection, and can also use a purely mechanical method to detect the pressure value in the negative pressure consumer 2 and control the The communication state of the air port 111a and the air inlet 111c.

[0081] Such as Figure 4 with Figure 5 As shown, the controller 11 has three gas circuit interfaces, which are the air outlet 111a, the air inlet 111c, and the detection port 111b. The communication state between the air outlet 111a and the air inlet 111c is controlled by the pressure state received by the detection port 111b. , when the pressure received by the detection port 111b is less than the set threshold, the gas outlet 111a is connected to the air inlet 111c, and the negative pressure system is in a constant flow state; when the pressure received by the detection port 111b is greater than the set threshol...

Embodiment 3

[0094] In the first embodiment, the first sealing ring 115 a , the second sealing ring 115 b and the third sealing ring 115 c are arranged on the outer surface of the piston 114 , and these sealing rings can also be arranged on the inner surface of the housing 111 .

[0095] Such as Figure 11 to Figure 15 As shown, the controller 11 includes a housing 111 and a piston 114. The outer side of the housing 111 is provided with through holes through the inner and outer walls, which are respectively an air outlet 111a, an air inlet 111c and a detection port 111b. Between the housing 111 and the piston 114 A sealing ring is provided, and the piston 114 slides inside the housing 111; when the pressure of the detection port 111b is greater than the pressure threshold (when the controller 11 is not installed and used, the port is free when the port is connected to the atmosphere), the air outlet 111a, the air inlet 111c and the The detection ports 111b communicate with mutually indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com