Typical fault simulation method for ethylene-propylene rubber cable terminal insulation layer

A technology of ethylene-propylene rubber insulation and ethylene-propylene rubber, which is applied in the direction of fault detection, fault location, and electrical measurement according to conductor type, which can solve the problems of limited recognition effect and low recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, the present invention will be further described in conjunction with the embodiments.

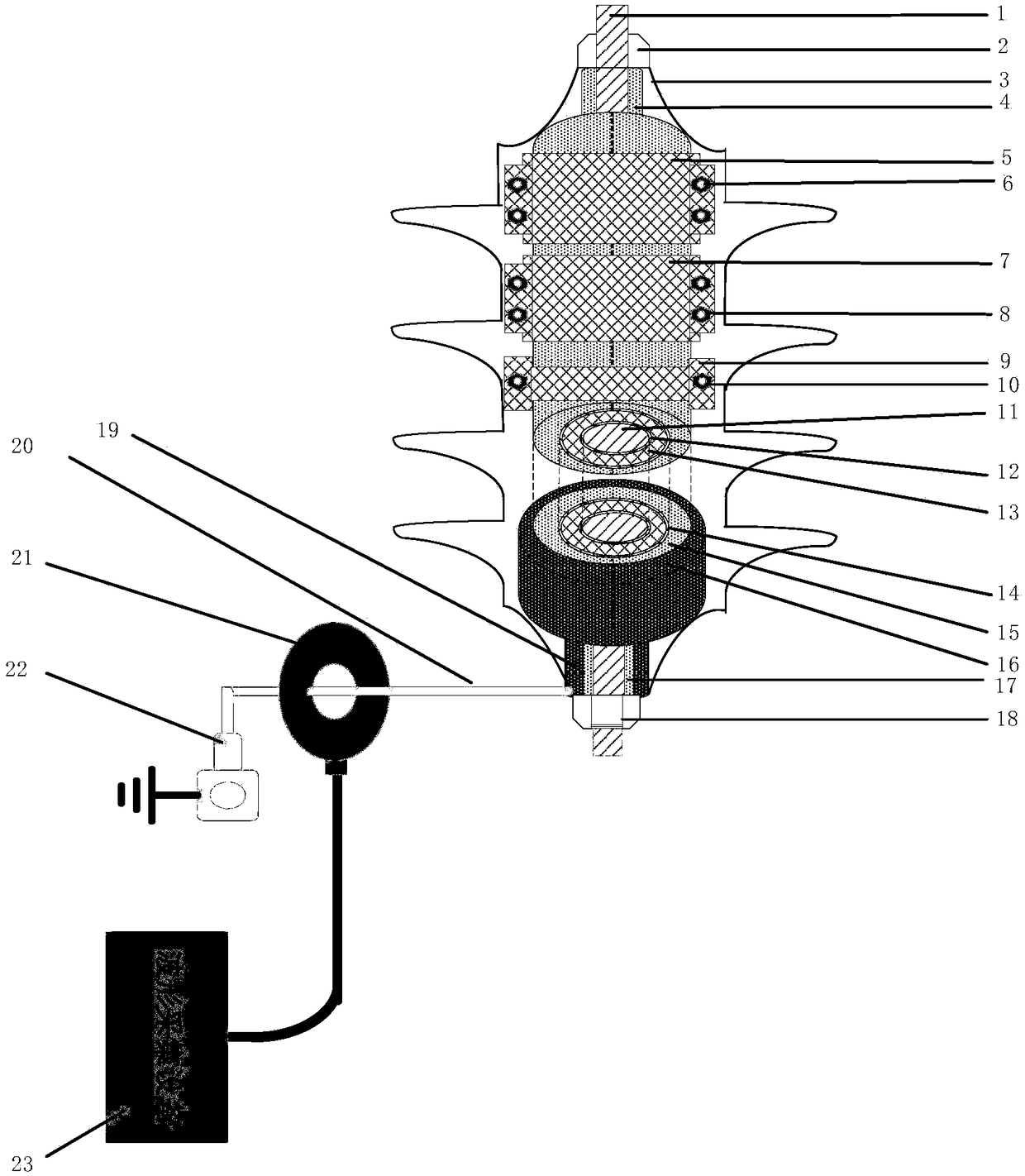

[0055] figure 1 It is a schematic diagram of the fault simulation of the ethylene-propylene rubber cable terminal for high-speed trains, including the cable core plug (1), the upper fastening rubber plug (2), the cold shrinkable outer umbrella skirt (3), the upper port insulating sleeve (4), First U-shaped fastener (5), first fastening bolt (6), second U-shaped fastener (7), second fastening bolt (8), third U-shaped fastener (9) , The third fastening bolt (10), the inner copper core (11), the first semi-conductive layer (12), the ethylene propylene rubber insulation layer (13), the second semi-conductive layer (14), the outer fastening sheath layer (15), external copper mesh layer (16), lower port insulation sleeve (17), lower fastening rubber plug (18), metal shield sleeve (19), copper ground wire (20), pulse coupler ( 21), copper wire interface (22), waveform acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com