A method for simulating and testing the faults of different degradations of the insulating layer of ethylene-propylene rubber cable terminals

An ethylene-propylene rubber insulation and fault simulation technology, which is applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve the problem that the evaluation results are not accurate enough, cannot sensitively reflect the insulation aging state, and cannot truly reflect the influence of the detection method, etc. problems, to achieve the effect of accurate assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

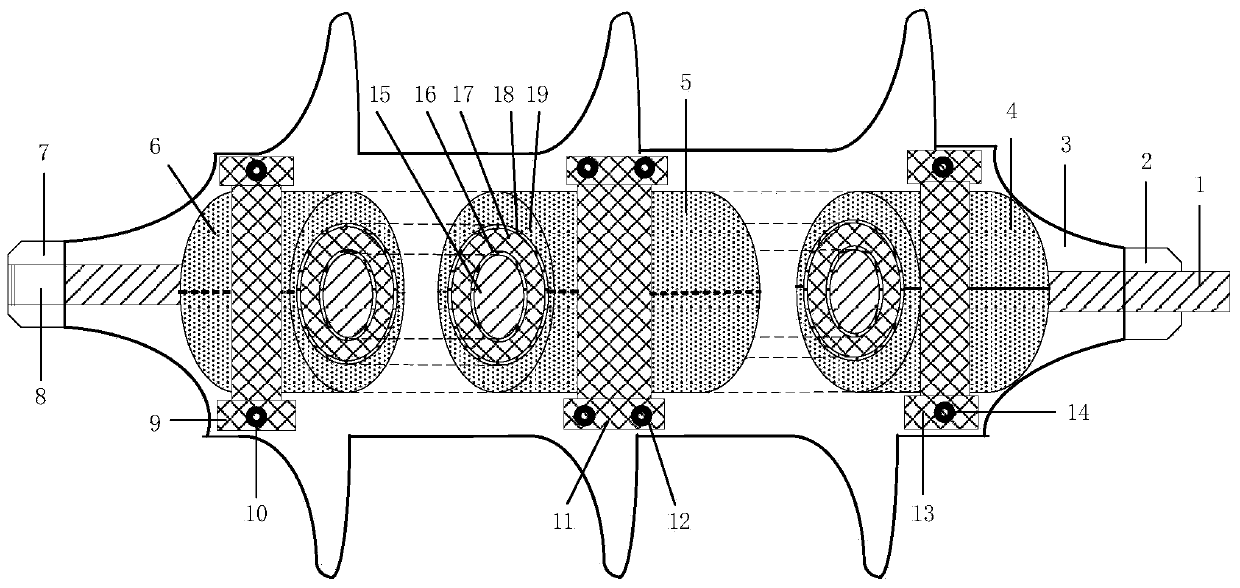

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] figure 1 It is a schematic diagram of the structure of the ethylene-propylene rubber cable terminal fault simulator for high-speed trains, including the terminal cable core plug (1), the right fastening rubber plug (2), the cold-shrinkable shed (3), the right fixed analog terminal ( 4), detachable fault analog terminal (5), left fixed analog terminal (6), left fastening rubber plug (7), terminal cable core jack (8), left U-shaped fastening component (9) , fastening bolts (10), middle U-shaped widening fastening components (11), double fastening bolts (12), right U-shaped fastening components (13), fastening bolts (14); right side fixing simulation end (4), the detachable fault analog end (5), and the fixed analog end on the left (6) are all composed of a first metal layer (15), a first semiconducting layer (16), and a concentric circle structure from inside to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com