Method for manufacturing three-dimensional memory and three-dimensional memory

A manufacturing method and memory technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as poor channel hole morphology, achieve the effects of reducing roughness, eliminating aliasing, and improving storage and erasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The manufacturing method of the three-dimensional memory and the specific implementation of the three-dimensional memory provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

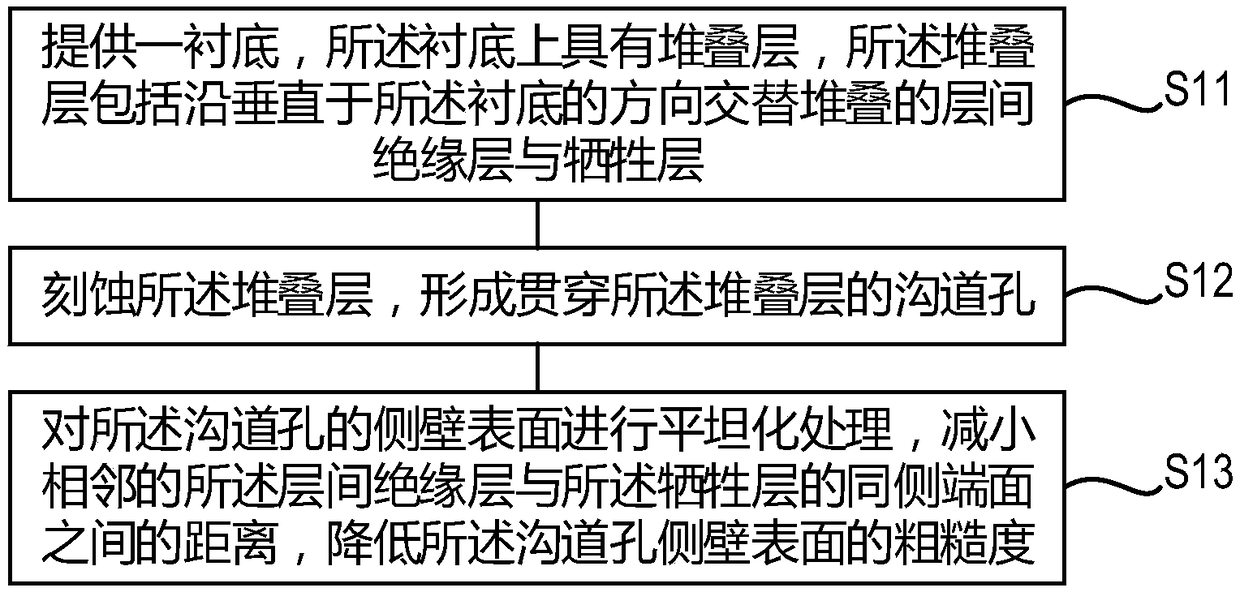

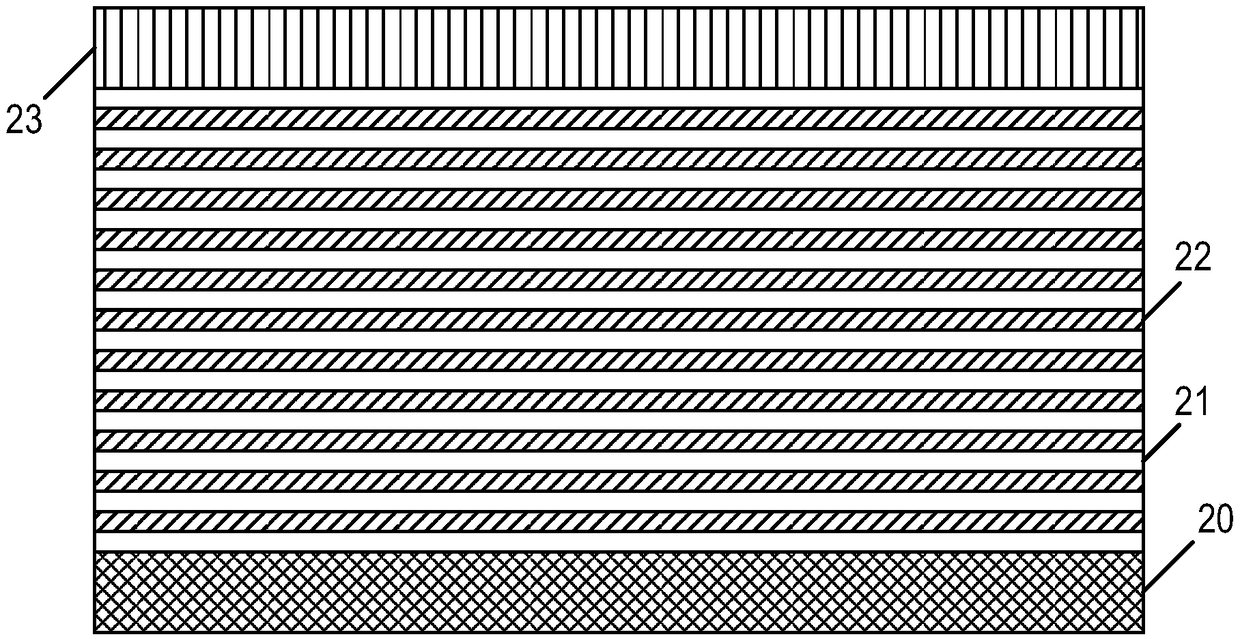

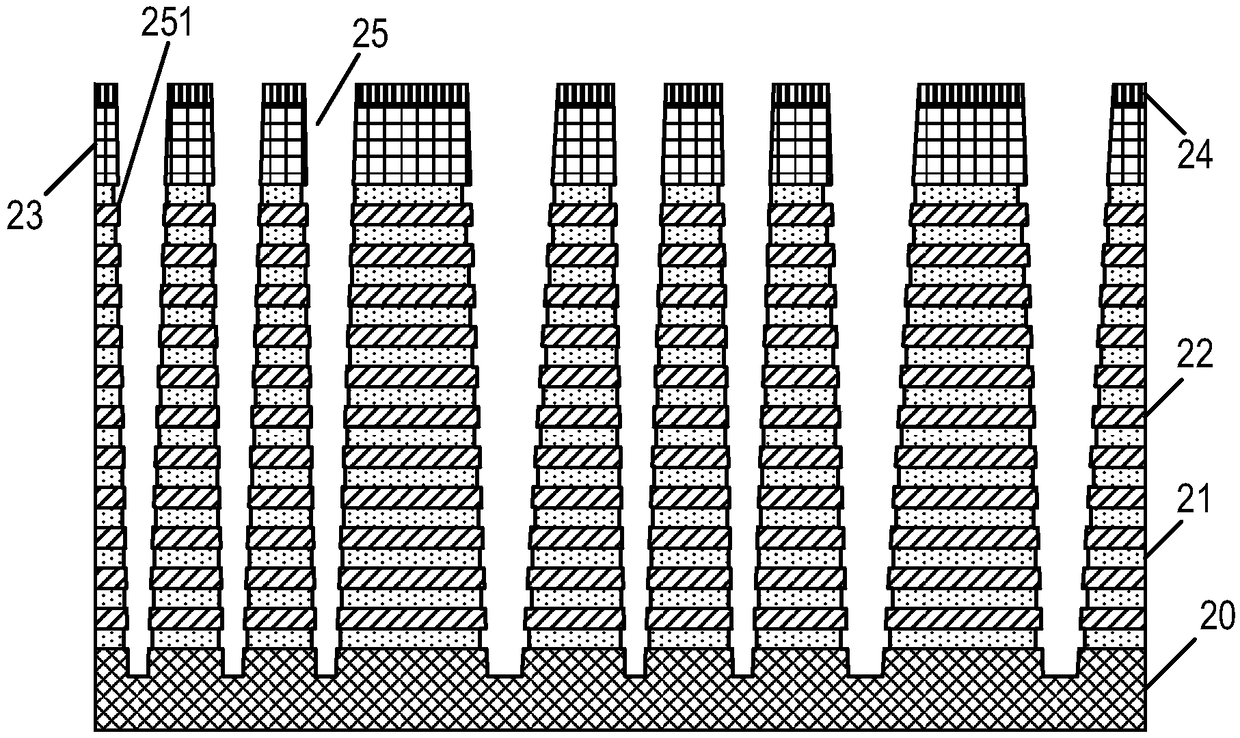

[0047] In the manufacturing process of a three-dimensional memory, firstly, a stacked layer composed of interlayer insulating layers and sacrificial layers stacked alternately along the direction perpendicular to the substrate is formed, and then formed by metallization steps A stack structure composed of stacked interlayer insulating layers and gate layers. Wherein, the metallization step refers to: removing the sacrificial layer in the stacked layers to form a gap region between adjacent interlayer insulating layers; and then filling the gap region with conductive material to form a gate layer. In order to realize the control of the memory cells, a channel hole penetrating through the stacked layers is formed through a dry etching pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com