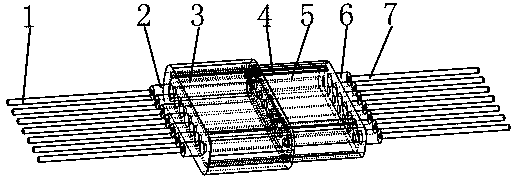

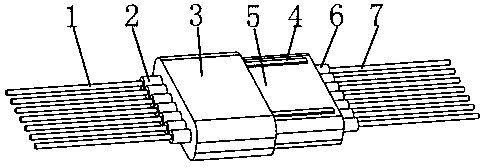

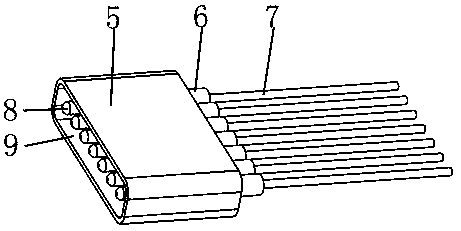

A high-voltage wire connector used in the electric power industry

一种高压电线、电力行业的技术,应用在接触部件、电气元件、连接装置的零部件等方向,能够解决安装工人安装工作麻烦、插接不容易、高压电线插接件不容易插入等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0063] The specific embodiment is as follows: when the first fixed shell 3 and the second fixed shell 5 are not installed, the second limit block 49 in the first fixed shell 3 and the second limit groove 50 are distributed in the opposite direction, and the second plate spring 47 In a compressed state; when the installer needs to connect the first fixed shell 3 and the second fixed shell 5 together, the installer at this time inserts the second fixed shell 5 into the first container opened on the first fixed shell 3 In the cavity 12, when the side of the first rack 4 on the second fixed shell 5 is inserted into the first accommodating cavity 12 and the displacement is large, the first rack 4 drives the second gear 23 to have a rotating tendency. At this time, the first square 26 has a tendency to rotate under the driving of the first gear 22, when the first block 26 will be restricted by the second guide groove 35 opened on the second guide block 21, so that the first block 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com