Stirring device for dyes applied to textile threads

A stirring device and textile thread technology, applied in the direction of mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of immovability, single function, and unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

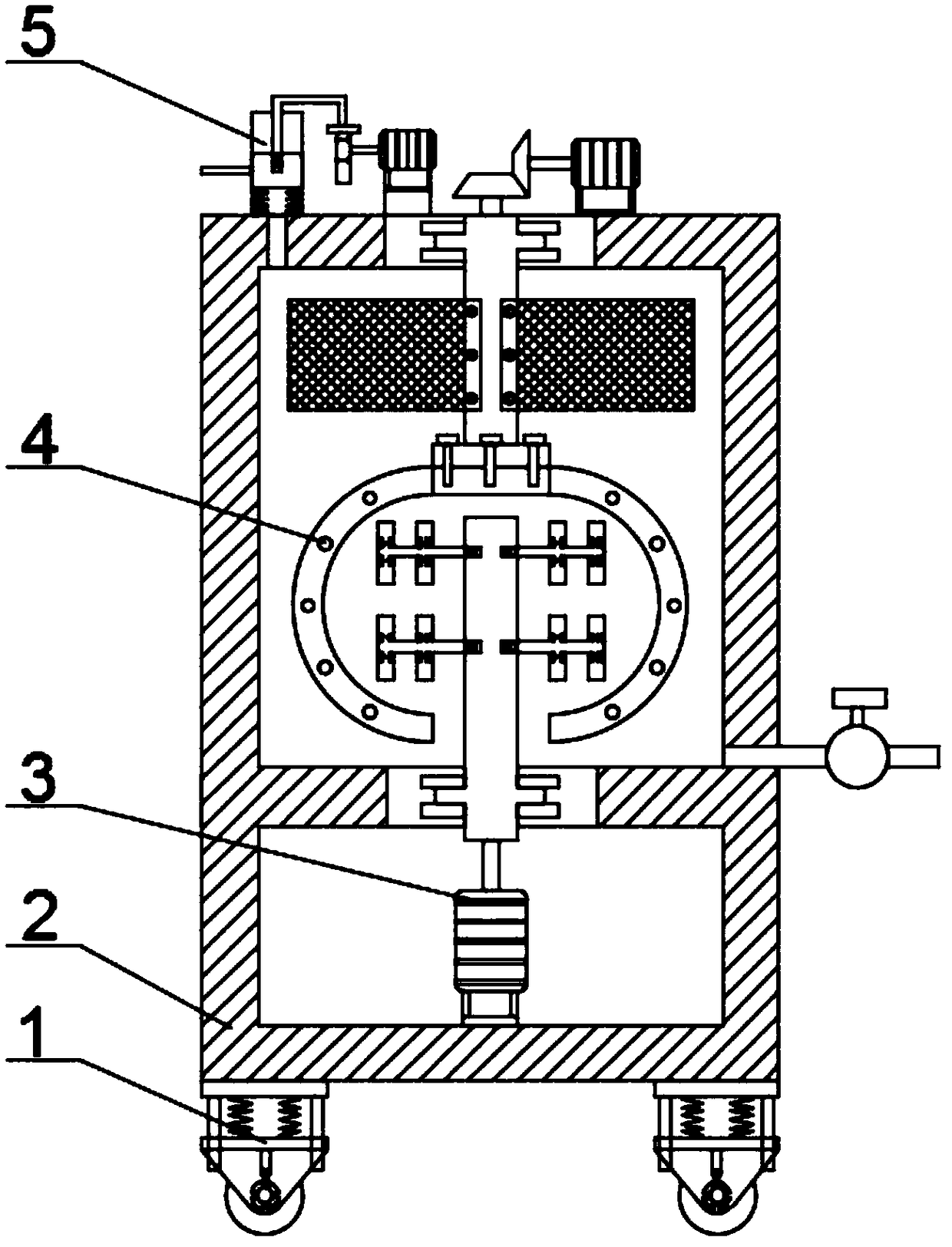

[0038] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 To illustrate this embodiment, the present invention relates to a stirring device, more specifically, a stirring device for textile thread dyes, including a moving shock-absorbing parking wheel mechanism 1, a body mechanism 2, a first stirring mechanism 3, and a second stirring mechanism 4 , Feeding mechanism 5, the device can stir the dye through two working modes, the device can filter out impurities in the dye, the device can automatically feed the dye, the device can move and withstand small vibrations during the movement, the device can Realize the parking function.

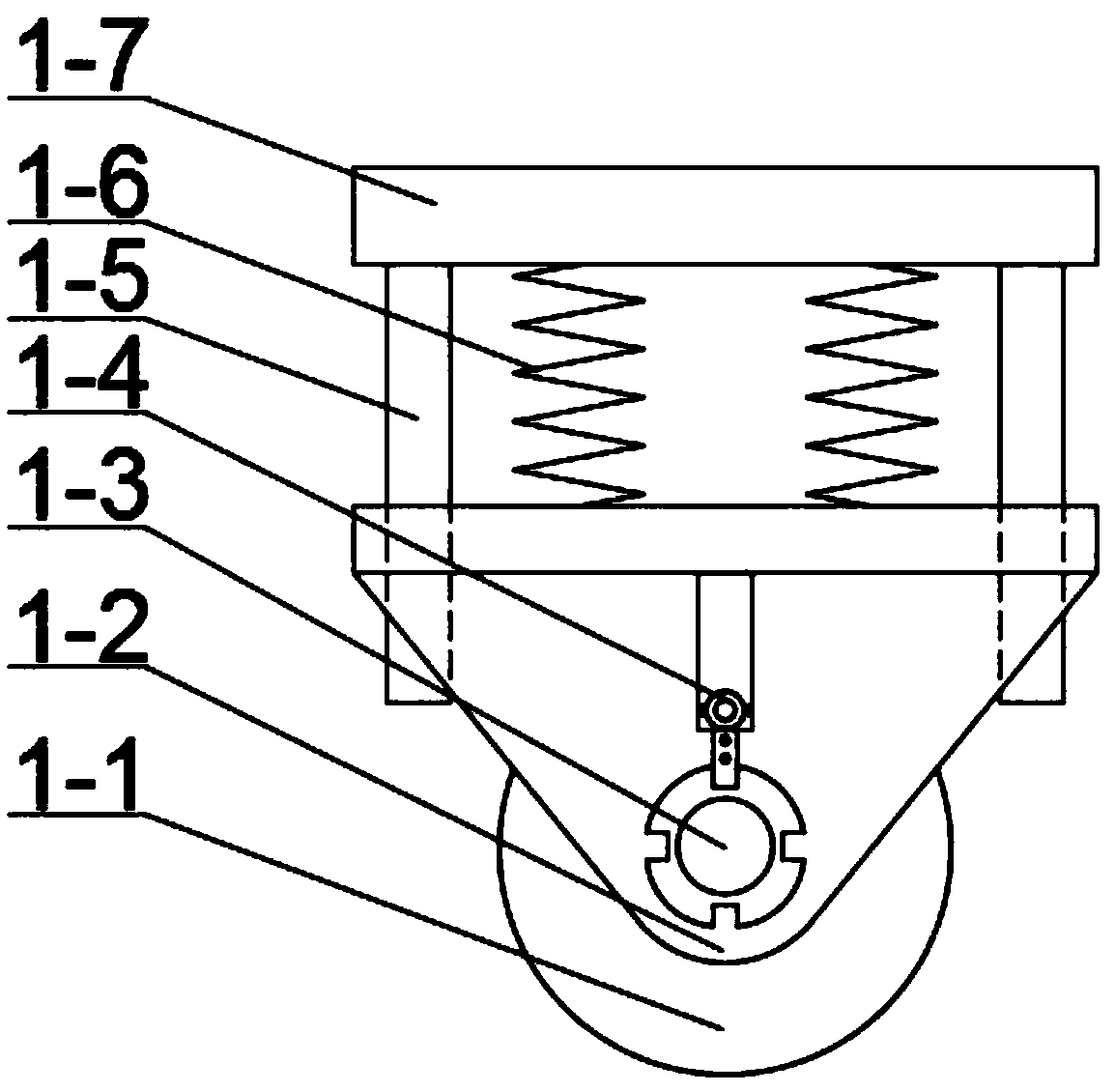

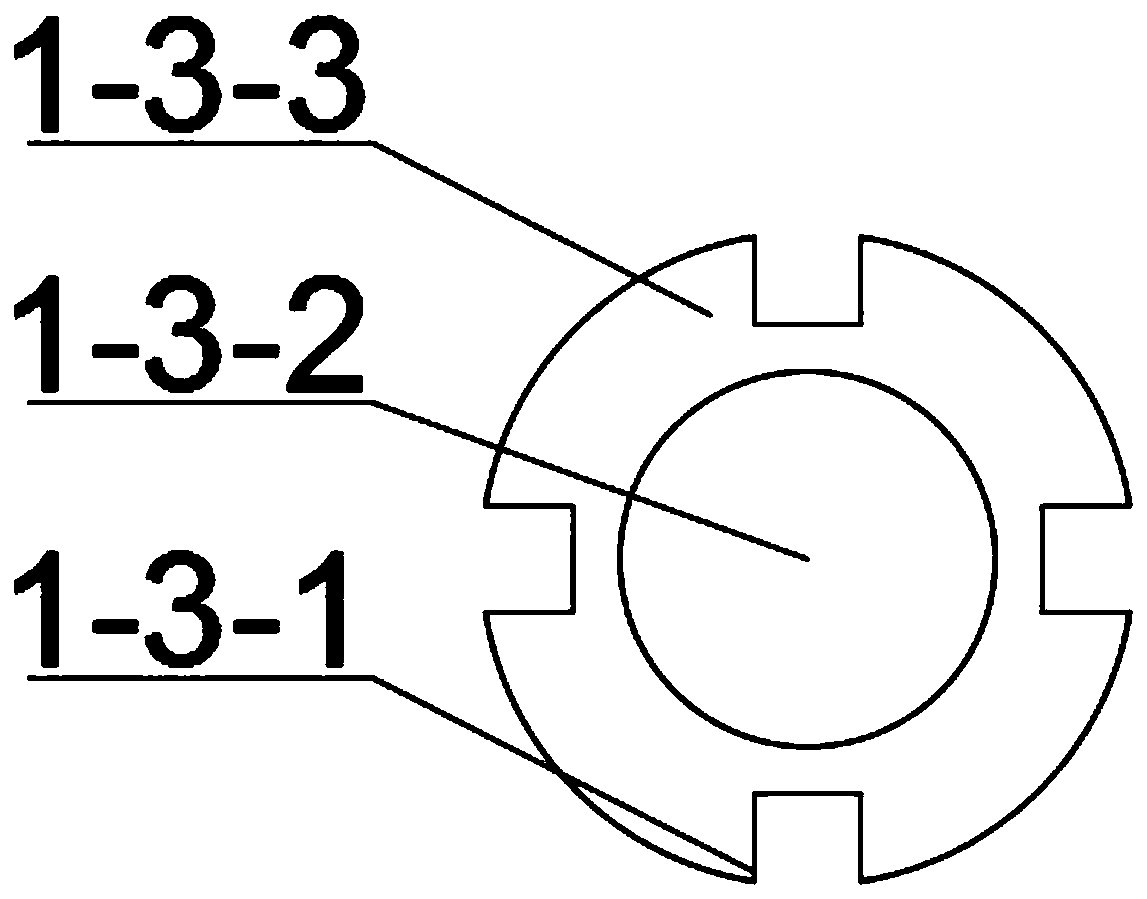

[0039] The mobile damping and parking wheel mechanism 1 includes a mobile wheel 1-1, a mobile wheel bracket seat 1-2, a limit shaft wheel 1-3, a telescopic limit rod 1-4, an anti-bias rod 1-5, and a shock absorbing spring ...

specific Embodiment approach 2

[0052] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 This embodiment will be described. This embodiment will further describe Embodiment 1. The number of the filter plate slots and filter plates is four.

specific Embodiment approach 3

[0053] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 This embodiment will be described. This embodiment will further describe Embodiment 1, and the material of the damping spring is high carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com