A kind of micropowder grading equipment

A technology of micropowder and equipment, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of low classification efficiency and wide product particle size distribution, and reduce labor intensity and load capacity Effects with a wide range and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

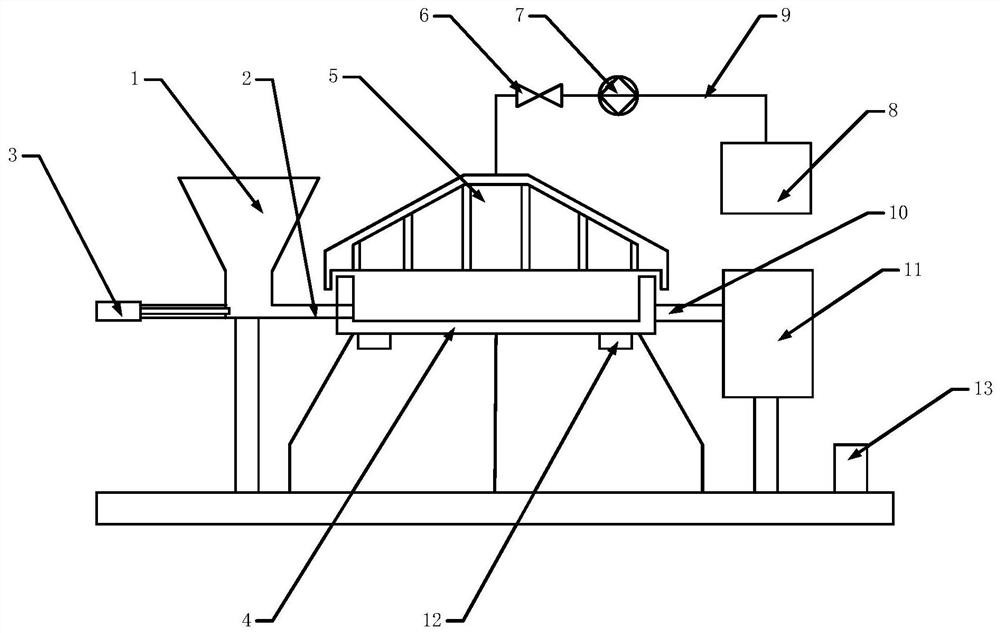

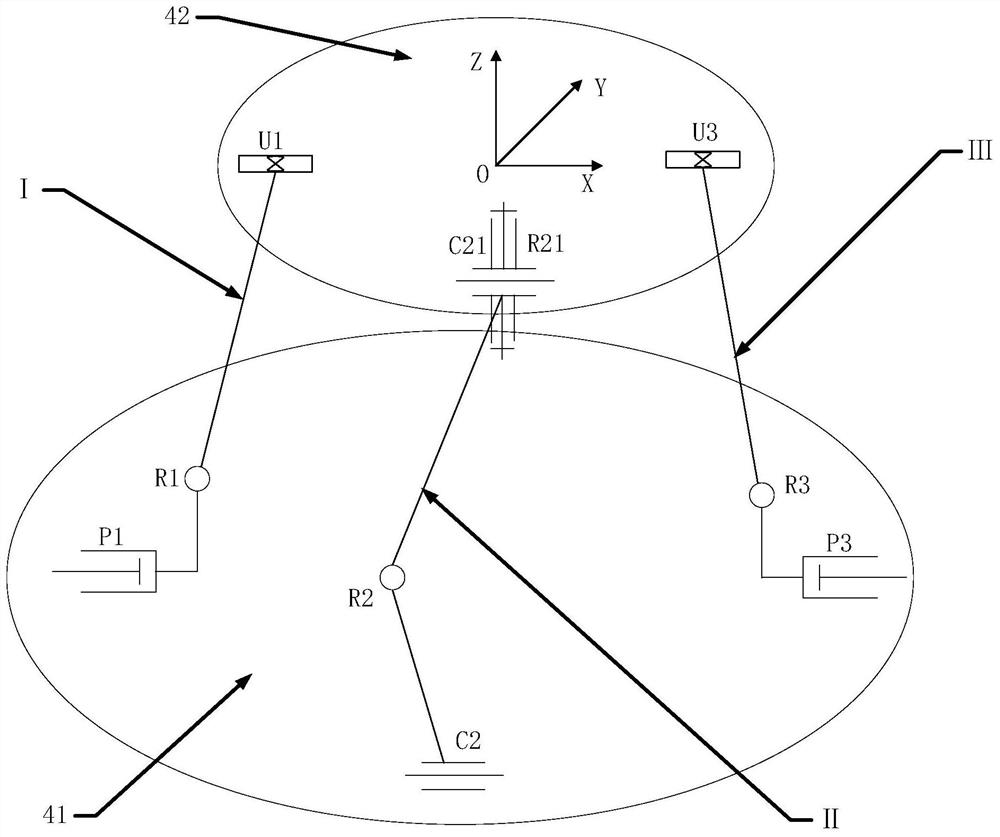

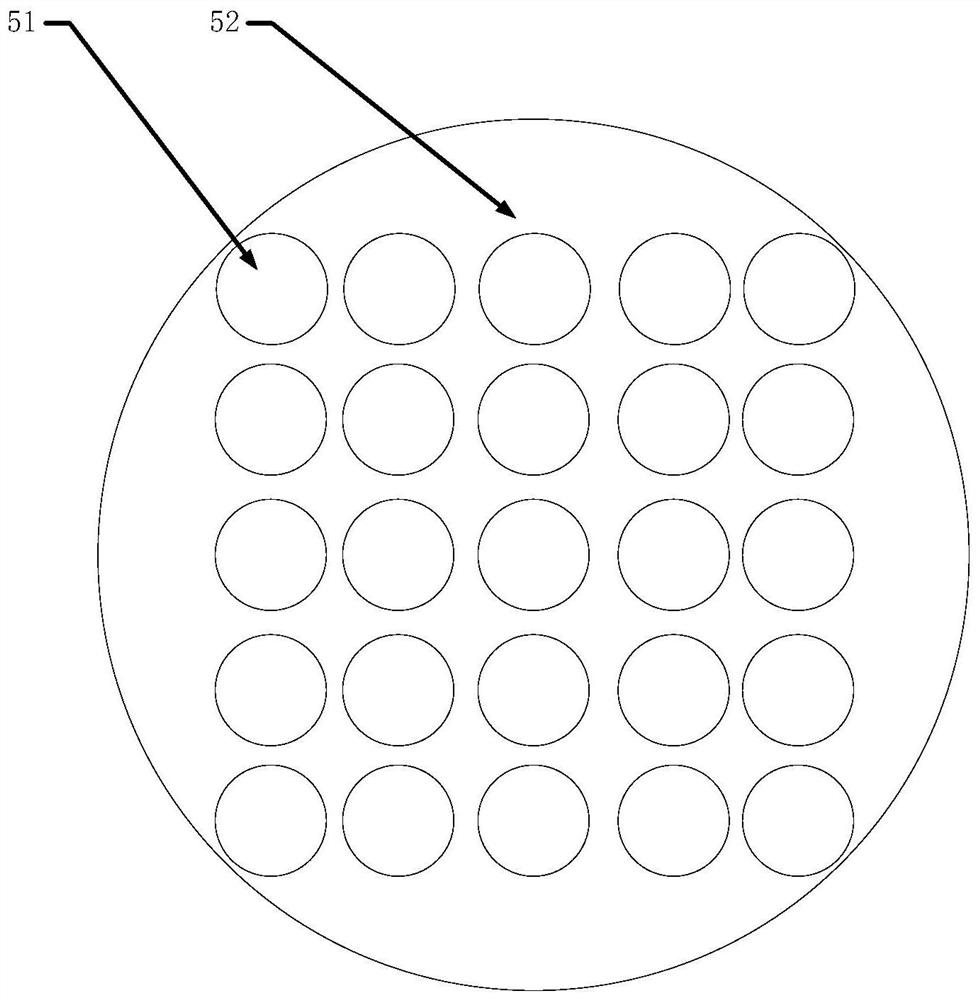

[0022] A new type of fine powder classification equipment, such as figure 1 As shown, the grading equipment includes: feed port 1, feed pipe 2, piston rod 3, parallel excitation table 4, grading suction cup 5, solenoid valve 6, air pump 7, collection chamber 8, gas pipeline 9, Discharge pipe 10, recovery chamber 11, PLC13, position sensor 12. The feed port is connected to the feed pipe, located in the middle of the feed pipe, for feeding the micropowder raw material; the tail end of the feed pipe is provided with a piston rod, and the piston rod is used to pass the micropowder raw material through the feed pipe Push it onto the parallel vibration table, and the front end of the feed pipe is flexibly connected to the parallel vibration table; above the parallel vibration table, there is a graded suction cup, which will completely cover the parallel vibration table, but both There is no direct contact, and there is a specific gap value between the two, and the gap value in the ...

Embodiment 2

[0026] A new type of fine powder grading equipment, its overall structure is as follows Figure 4 As shown, the PLC is electrically connected to the upper computer, the piston rod, the solenoid valve, the air pump, the position sensor, the driver 1, the driver 2 and the driver 3 respectively. The PLC is connected to the upper computer for setting the feeding times of the piston rod, the type of micropowder particles, the particle size range to be sorted, the suction time and other parameters; the PLC is connected to the piston rod and used to control the switch of the piston rod , so as to control the feeding times of the piston rod; the PLC is connected with the electromagnetic valve, and the electromagnetic valve is connected with the air pump, and is used to control the switch of the air circuit, and set the pumping rate of the air pump, thereby controlling the opening time of the air circuit; The PLC is connected with the driver 1, the driver 2, and the driver 3, and the d...

Embodiment 3

[0028] A new type of micro-powder grading equipment, using PC+PLC servo control system, its overall structure is as follows Figure 4 As shown, the piston rod, the three driving motors of the parallel excitation table, the solenoid valve, the air pump, and the position sensor are all controlled by the PLC controller, and the PLC communicates with the PC host computer through the R232 serial port. The workflow of the device is as follows Figure 5 Shown:

[0029] 1) After the equipment is powered on, the control system is initialized, and the position sensor and solenoid valve are set;

[0030] 2) Add micropowder raw materials through the feeding port, then enter the feeding pipe, start the piston rod, push the micropowder raw materials into the parallel excitation table, and check whether the feeding is completed, if not, the piston rod continues to work until all Micropowder raw materials are pushed into the parallel excitation table;

[0031] 3) Select the type of micropo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com