Automatic angle adjusting device for rear-view mirror of cart

An automatic adjustment, rear-view mirror technology, used in optical observation devices, vehicle components, transportation and packaging, etc., can solve problems such as inner wheel difference blind spots, and achieve the effect of eliminating visual blind spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

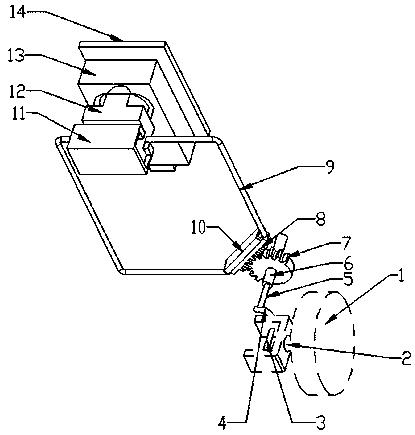

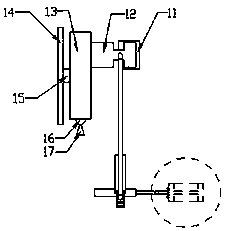

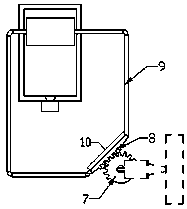

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a rearview mirror angle automatic adjustment device for a large vehicle is composed of a steering knuckle arm 4, a spline shaft 5, a spline sleeve 6, a sector gear 7, a rack 8, a cable 9, a rack guide rail 10, and a driving cam Guide rail 11, rearview mirror active cam 12, rearview mirror driven cam 13, rearview mirror 14 and fixed bracket 17, the steering knuckle arm 4 is connected to the steering knuckle 2 through the kingpin 3, and the steering knuckle 2 is connected to the tire 1 , the spline shaft 5 is fixed on the steering knuckle arm 4, the rack guide rail 10 is fixed on the vehicle body, the rearview mirror 14 is connected to the vehicle body through a fixed bracket 17, and the rear part of the rearview mirror 14 is connected to the rear through a ball joint 15 The mirror driven cam 13 is connected, the active cam guide rail 11 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com