A GDX6S large oil seal loading trolley

A technology for loading trolleys and oil seals, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., and can solve the problems of manual addition of auxiliary materials and increased labor intensity of machine operators and maintenance personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

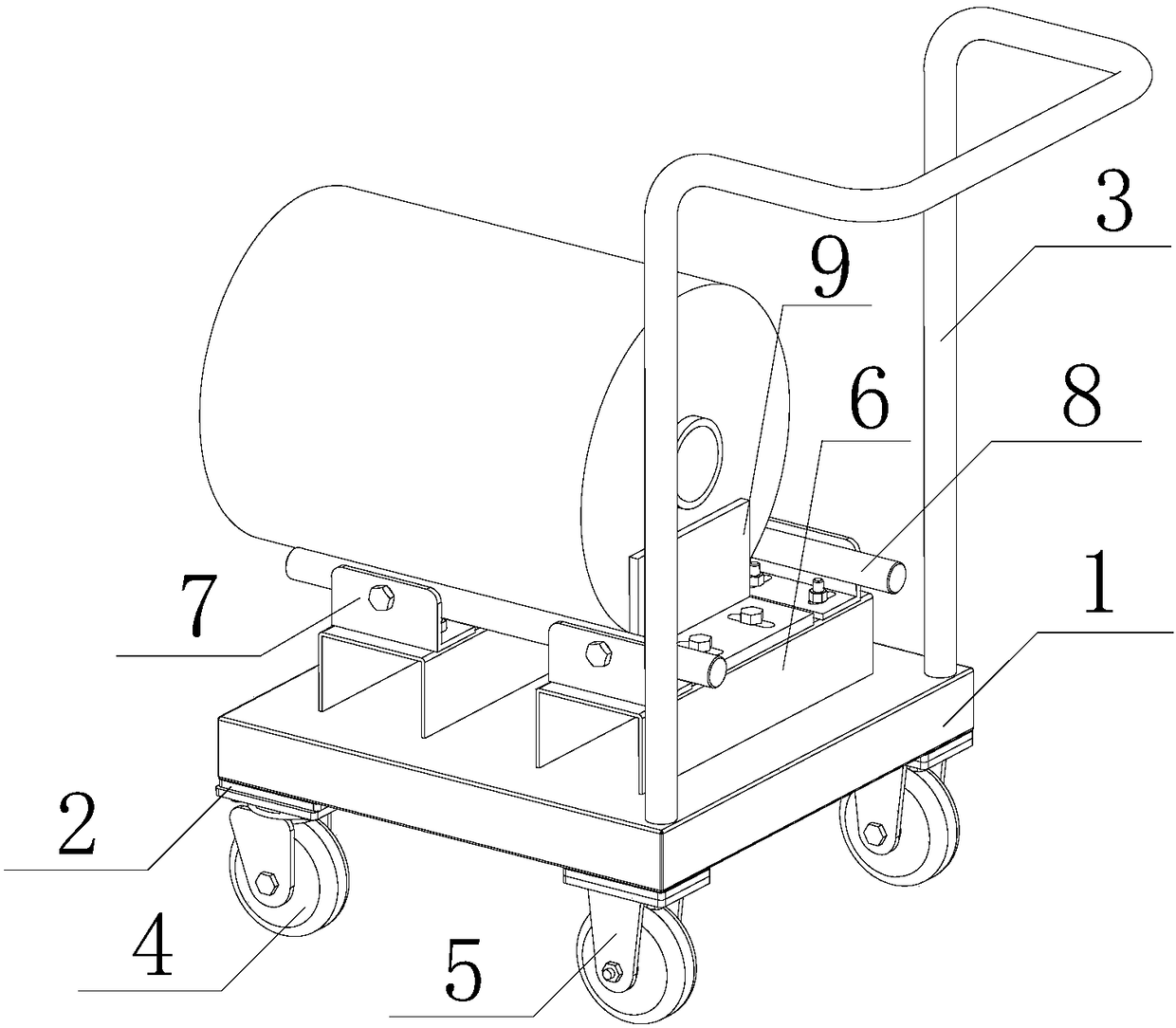

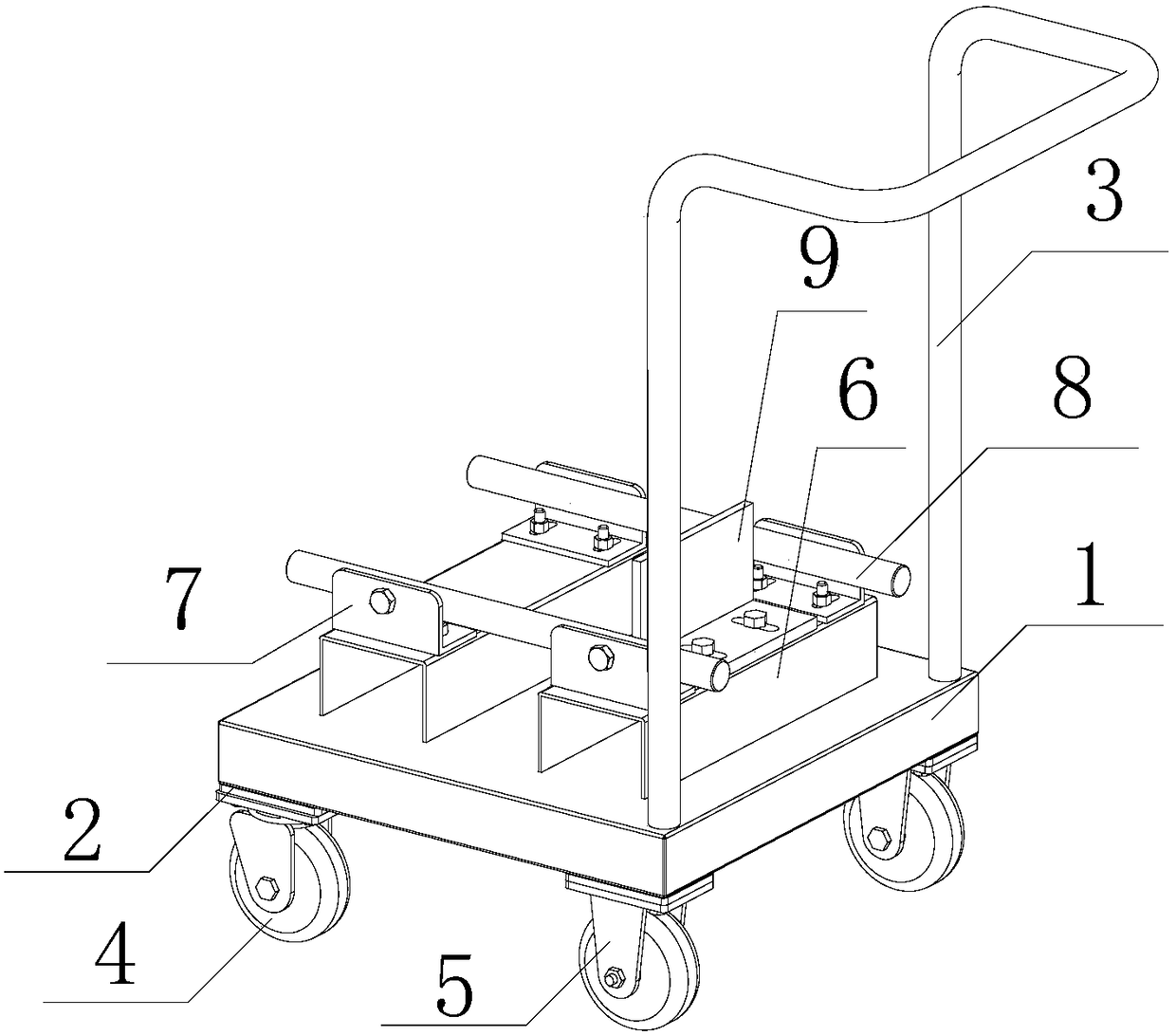

[0024] The technical solutions of the present invention are described in detail below in conjunction with the embodiments and corresponding drawings, so that those skilled in the art can understand the solutions of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

[0025] The invention provides a loading trolley. Compared with the prior art, the invention realizes the installation of the GDX6S large oil seal through the design of the GDX6S large oil seal loading trolley, and reduces the labor intensity of installing the GDX6S large oil seal.

[0026] Specifically, the GDX6S large oil seal loading trolley according to the present invention has a bottom plate, handrails, multiple pulleys, baffle plates and multiple angle steel brackets; the handrails are arranged on one side of the upper plane of the bottom plate, and the multiple The pulleys are arranged at the four corners of the lower plane of the bottom plate; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com