A ship hull manhole typhoon-resistant tooling device

A typhoon-resistant and tooling technology, which is applied to ship parts, ship construction, transportation and packaging, etc., can solve the problems of affecting assembly and welding work, delaying assembly and welding work, increasing clean water work, etc., achieving simple structure, reliable installation and positioning, and reduced The effect of air shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

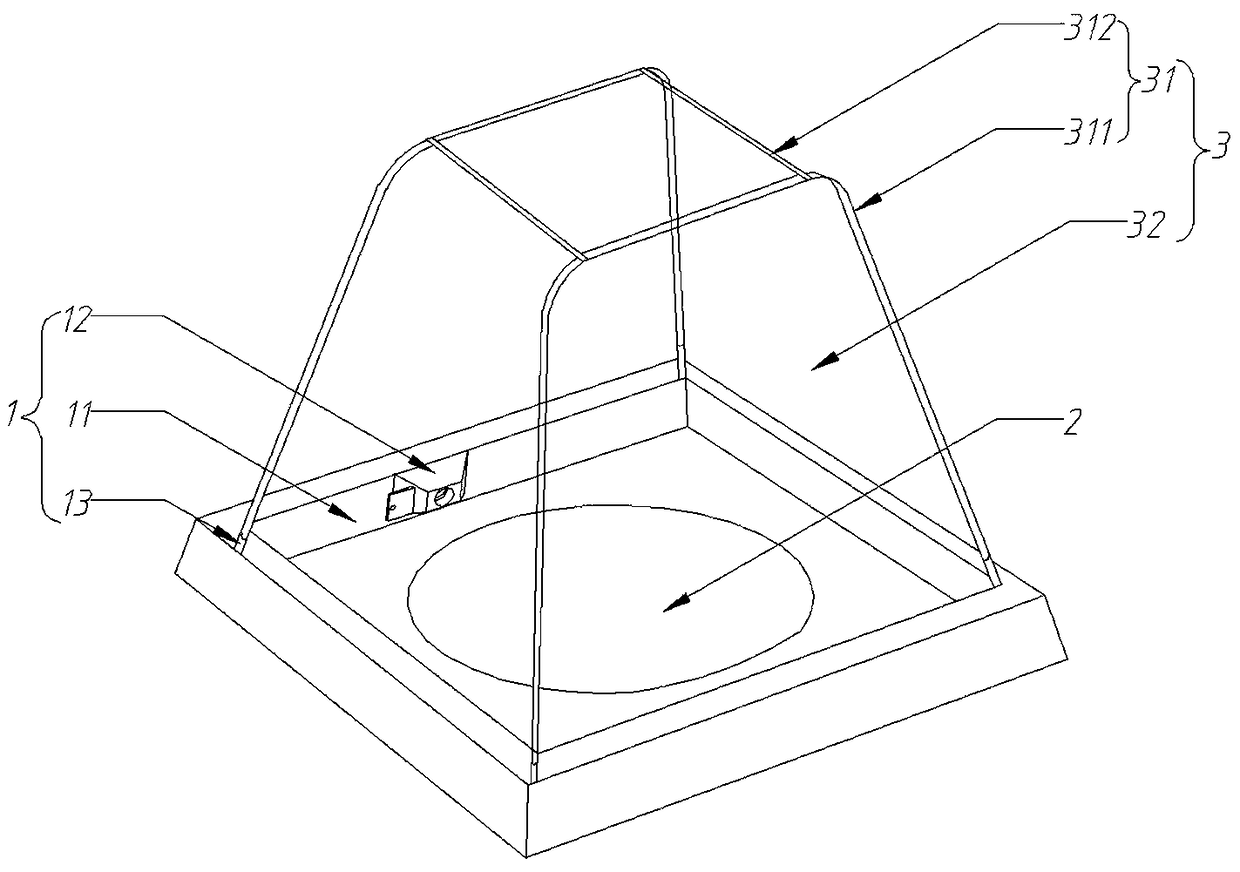

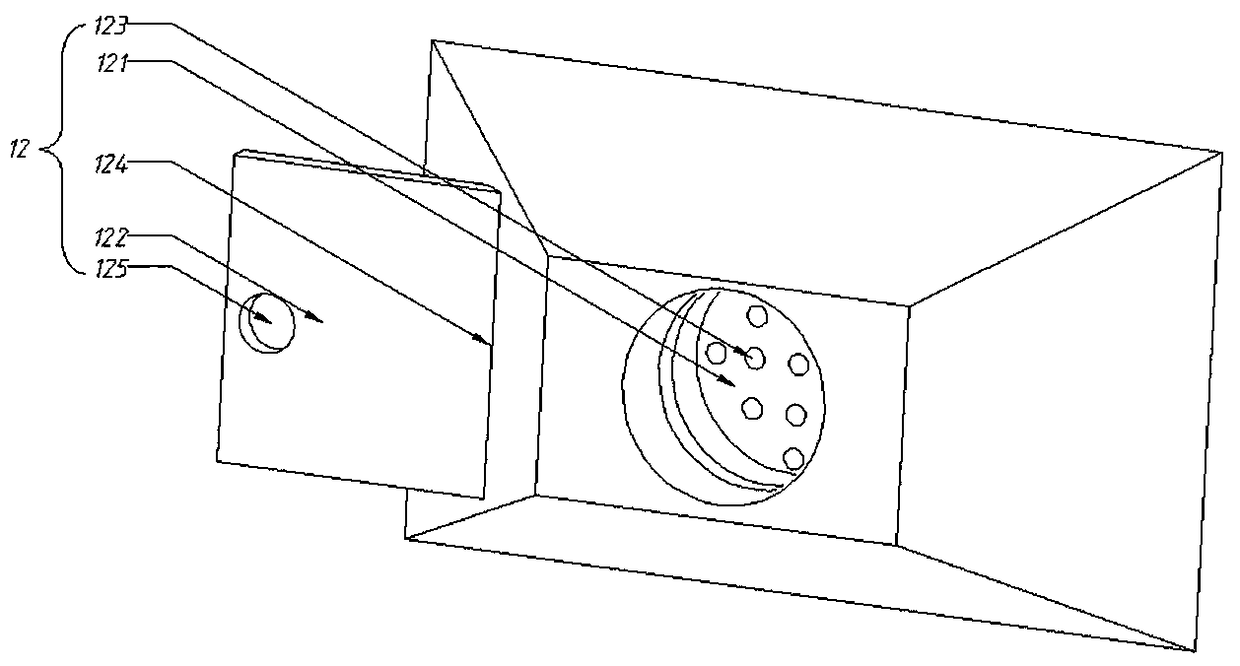

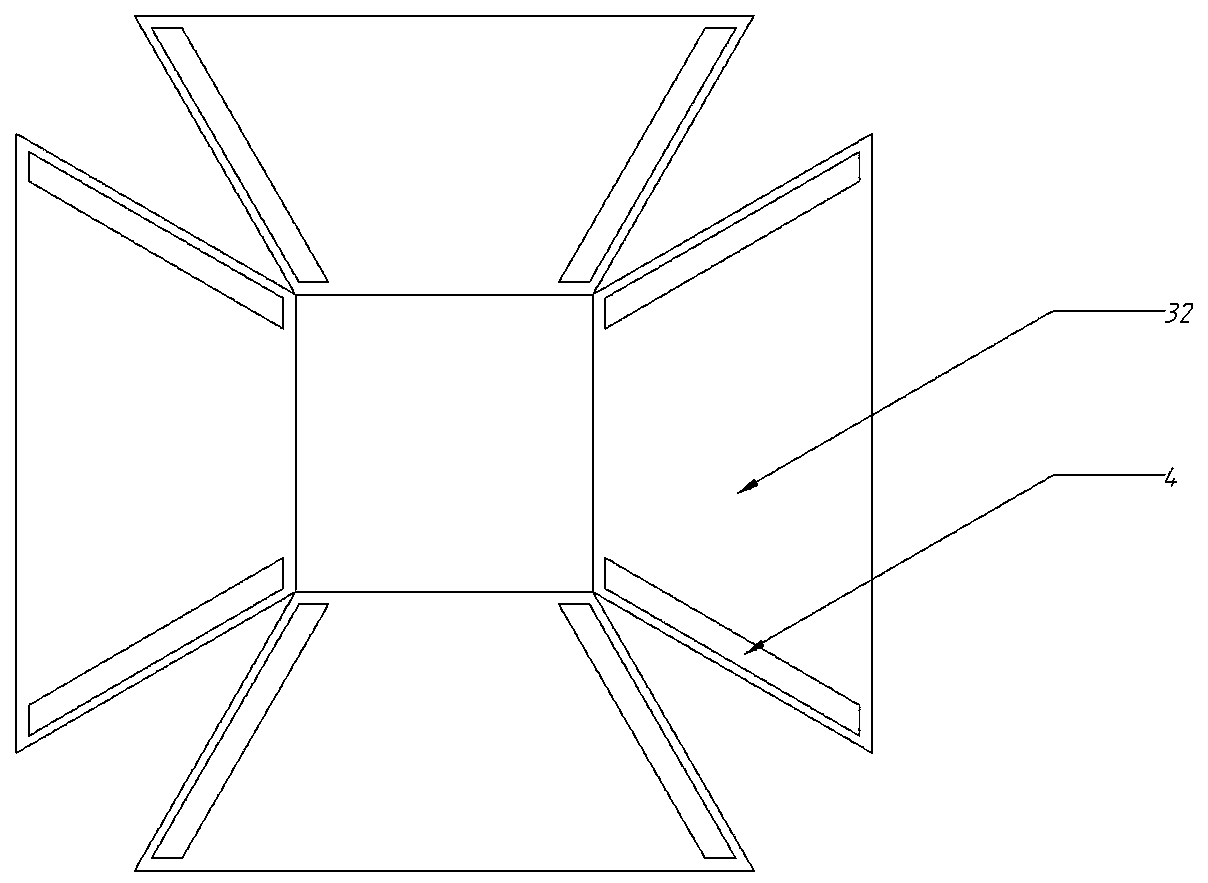

[0019] like Figure 1 to Figure 3 As shown, the specific embodiment of the present invention is: the present invention comprises locking device 1, the manhole that can enter cabin and manhole anti-typhoon frock 3, and described locking device 1 includes the annular vacuum that is arranged on the periphery of described manhole Concave sheet metal 11, the side wall of the annular vacuum concave sheet metal 11 is provided with a first through hole, and the first through hole is provided with a vacuum cover 12 suitable for the first through hole, and the first through hole The axis of the hole is on the same straight line as the geometric center of the vacuum plate cover, and several external bolts 13 are arranged on the upper surface of the vacuum concave sheet metal, and several external bolts 13 are connected with the manhole to resist typhoon. Tooling fits in 3 phases. The locking device 1 uses the principle of atmospheric pressure to prevent rainwater intrusion. The locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com