Seal member for vehicle and electric relay component for vehicle

A technology for sealing components and vehicles, applied to vehicle parts, household components, vehicle connectors, etc., can solve problems such as dimensional changes, achieve the effects of suppressing softening, high sealing performance, and maintaining liquid repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

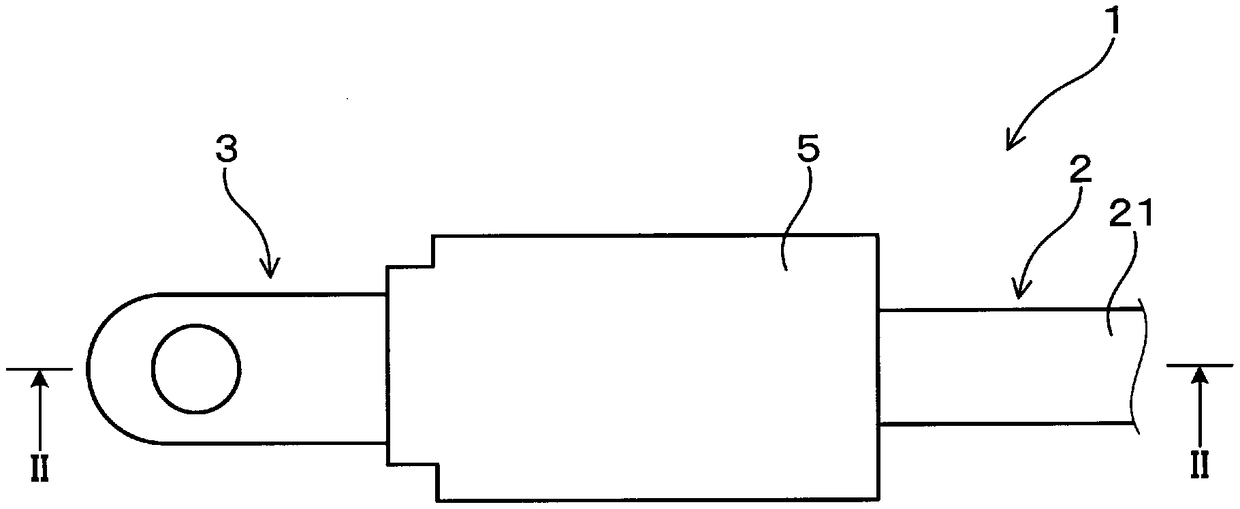

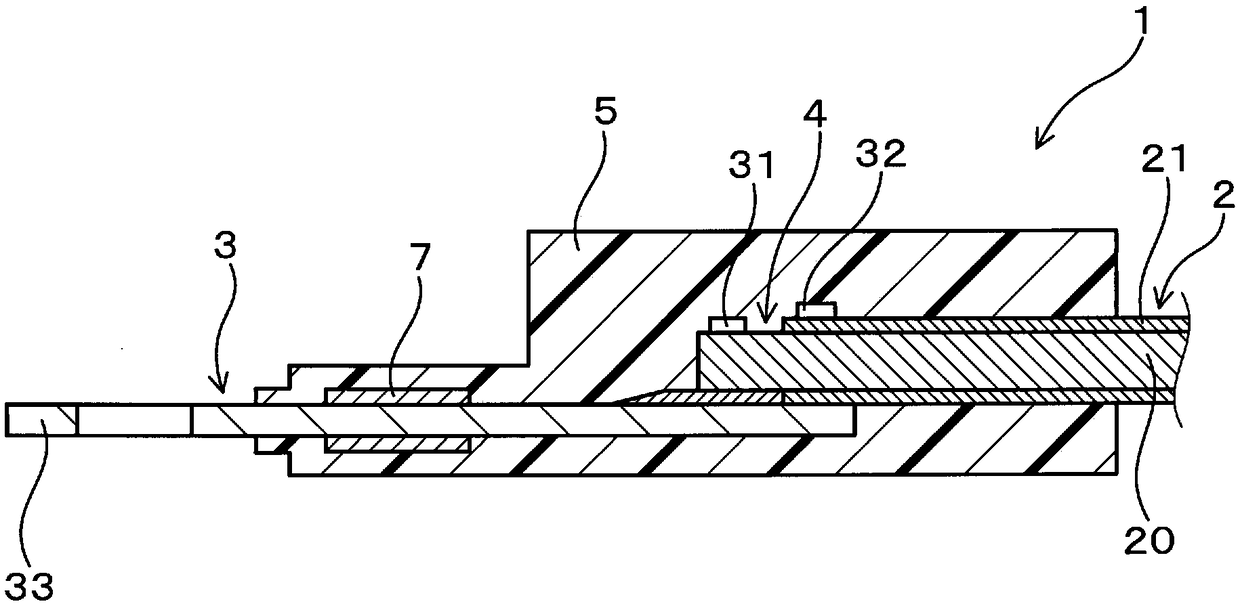

[0042] Such as figure 1 , figure 2 As shown, the vehicle power relay component 1 of this example has a terminal part 3, a molded resin part 5, and a sealing part 7, the terminal part 3 is connected to the conductor 20 of the electric wire 2, and the molded resin part 5 covers at least the terminal In the electrical connection portion 4 between the component 3 and the conductor 20 , the sealing portion 7 seals a gap formed between the terminal component 3 and the molded resin portion 5 . In this example, the terminal part 3 has a conductor crimping part 31 that crimps the conductor 20 of the electric wire 2 and an insulator crimping part 32 that crimps the insulator 21 of the electric wire 2 . In addition, in this example, the connection part 33 of the terminal part 3 connected to the target terminal part (not shown) protrudes from the molded resin part 5, and the part of the terminal part 3 closer to the electrical connection part 4 than the connection part 33 is buried. In...

Embodiment 2

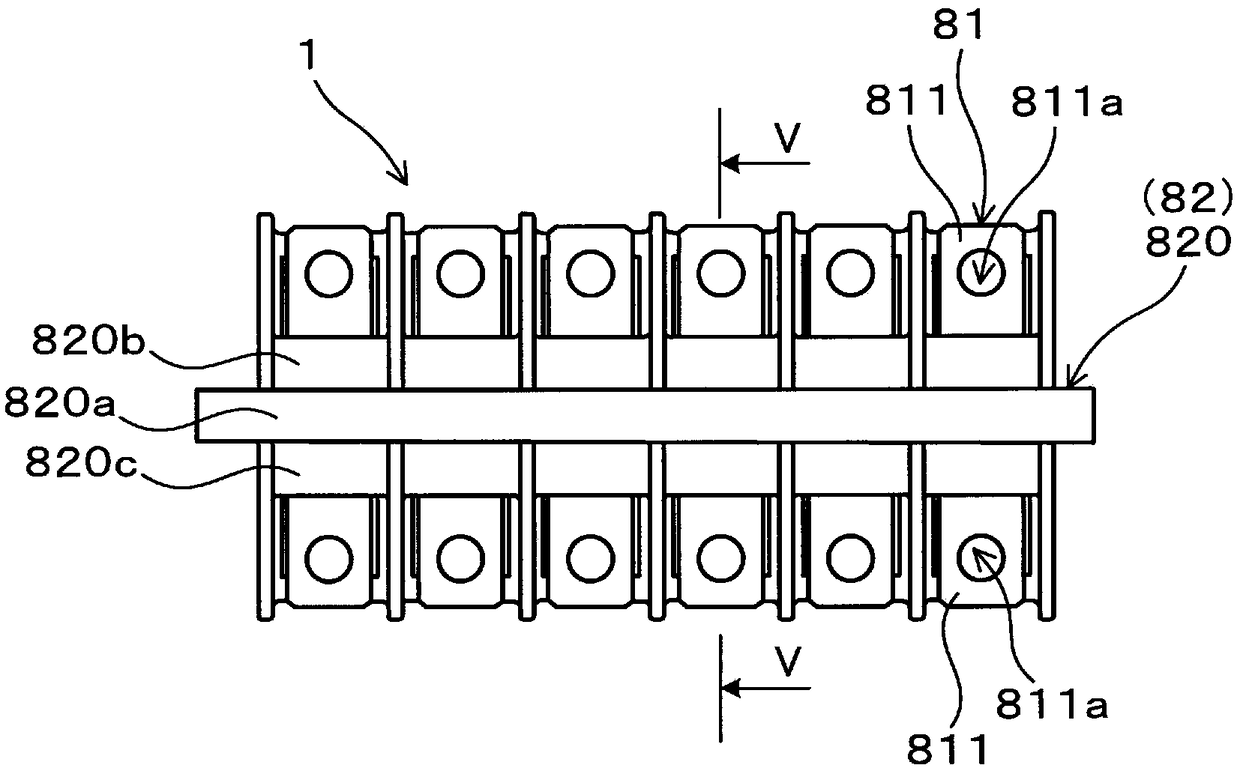

[0048] Such as Figure 3 ~ Figure 5 As shown, the vehicle power relay unit 1 of this example has a bus bar 81, a housing 82, and a sealing portion 7. The housing 82 has a molded resin portion 820 for fixing the bus bar 81, and the sealing portion 7 seals the bus bar 81 and the mold. The gap 83 between the resin parts 820 is plasticized. In the vehicle power relay component 1 of this example, the bus bar 81 is specifically configured to integrally include an embedded portion 810 embedded in a molded resin portion 820 and a connecting portion 811 protruding outward from the molded resin portion 820 . The sealing portion 7 seals the gap 83 existing between the embedded portion 810 and the molded resin portion 820 .

[0049] The molded resin portion 820 in the housing 82 is formed of thermoplastic resin in this example. Specifically, the thermoplastic resin is an aromatic polyamide resin (aromatic nylon resin) reinforced with glass fibers. Specifically, the molded resin part 82...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap