Nonaqueous dispersion of fluororesin, fluororesin-containing thermosetting resin composition using same and cured product thereof

A technology of thermosetting resin and fluororesin, which is applied in the field of non-aqueous dispersion of fluororesin, thermosetting resin composition of fluororesin using it and its cured product, and can solve the problem of covering film, flexible printed circuit Insulation effect of plate electrical properties, relative dielectric constant, deterioration of dielectric loss angle, unsuitable for high-speed communication, high-speed processing, etc., to achieve excellent storage stability, low dielectric constant, and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2 and comparative example 1~3

[0413] [Examples 1 and 2 and Comparative Examples 1 to 3: Preparation of thermosetting resin composition of fluorine-containing resin]

[0414] Using the obtained dispersions 1 to 4, a thermosetting resin composition of a fluorine-containing resin was produced with the compounding recipe shown in Table 3 below. In addition, Comparative Example 3 was produced as a composition consisting only of a resin to which no PTFE dispersion was added.

[0415] After mixing in the compounding ratios shown in Examples 1 and 2 and Comparative Examples 1 to 3, the PTFE dispersion and the resin were stirred and mixed uniformly using a disperser to obtain a thermosetting resin composition of a fluorine-containing resin .

[0416] Here, any compounding of Examples 1 and 2, and Comparative Examples 1 and 2 showed a very uniform state, and aggregates of PTFE and the like were not observed.

[0417] [table 3]

[0418] (parts by mass)

[0419]

Embodiment 3、4 and comparative example 4~6

[0420] [Examples 3 and 4 and Comparative Examples 4 to 6: Preparation of thermosetting resin cured products of fluorine-containing resins]

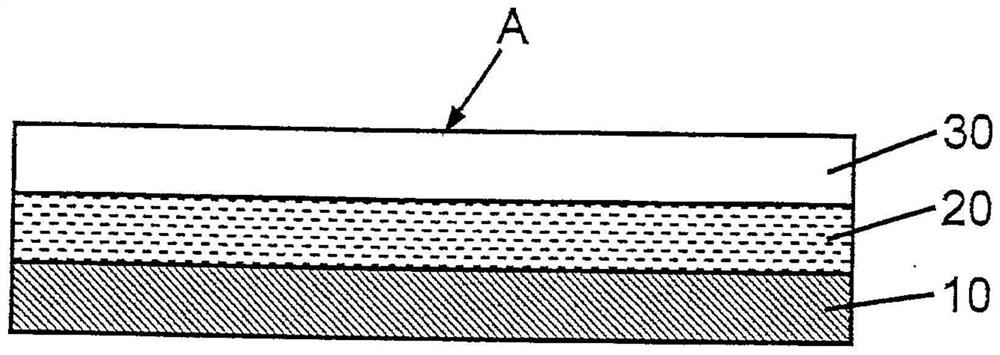

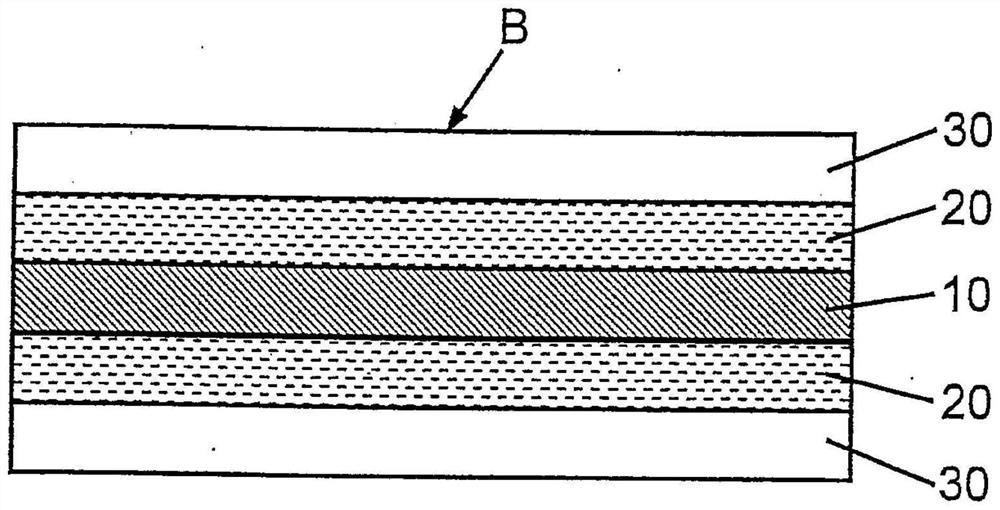

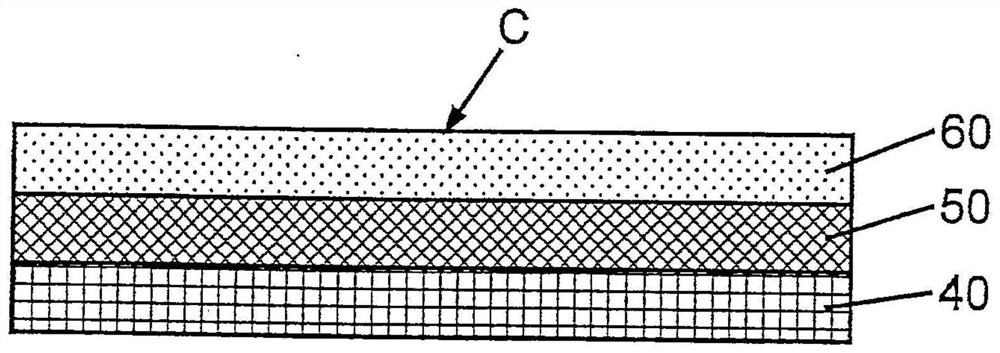

[0421] Using a coater, apply the thermosetting resin compositions of fluorine-containing resins obtained in Examples 1, 2, and Comparative Examples 1 to 3 to polyamide so that the thickness after drying becomes about 25 μm and becomes uniform. The entire surface of one side of the imide film (thickness: 25 μm) was dried at about 120° C. for about 10 minutes, and then cured by heating at 180° C. for 60 minutes to prepare a sample for relative permittivity evaluation.

[0422] 〔Evaluation of Relative Permittivity〕

[0423] The relative permittivity was measured at 1 GHz using an impedance analyzer (Impedence Analyzer) in accordance with the test standard of JIS C6481-1996.

[0424] [Evaluation of adhesion strength]

[0425] Copper foil (thickness 18 μm) roughened on one side was covered with a 100 μm thick sieve as a spacer, and the fluor...

Embodiment 5、6 and comparative example 7~9

[0444] [Examples 5 and 6 and Comparative Examples 7 to 9: Preparation of thermosetting resin compositions of fluorine-containing resins]

[0445] Using the obtained dispersions 5 to 8, a thermosetting resin composition of a fluorine-containing resin was produced with the compounding recipe shown in Table 7 below. In addition, Comparative Example 9 was produced as a composition consisting only of a resin to which no PTFE dispersion was added.

[0446] After mixing at the compounding ratios shown in Examples 5 and 6 and Comparative Examples 7 to 9, the PTFE dispersion and the resin were stirred and mixed uniformly using a disperser to obtain a thermosetting resin composition of a fluorine-containing resin .

[0447] Here, the compounds of Examples 5 and 6, and Comparative Examples 7 and 8 all showed a very uniform state, and aggregates of PTFE and the like were not observed.

[0448] [Table 7]

[0449] (parts by mass)

[0450]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com