Low-noise vortex fuel pump

A fuel pump, low noise technology, applied in the field of vortex fuel pump, can solve the problems of large noise, strong mutual impact, large pressure pulsation of the fuel pump, etc., to achieve the effect of reducing noise and alleviating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

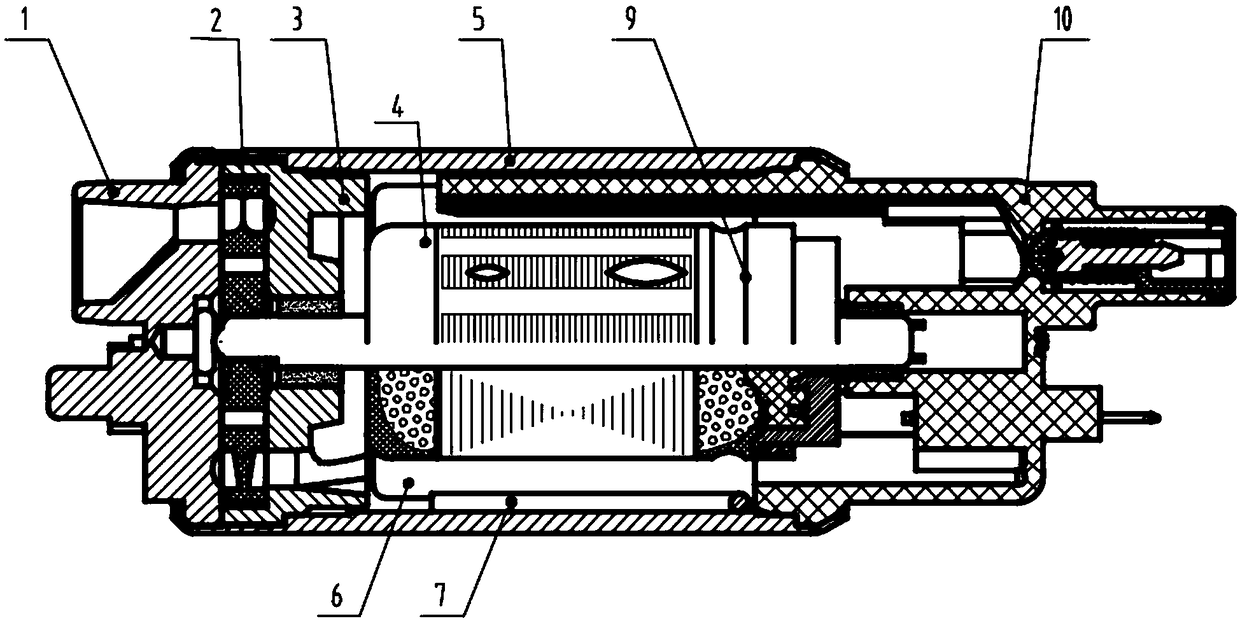

[0029] like figure 1 As shown, a low-noise vortex fuel pump includes a fuel pump body and an oil inlet assembly arranged at the oil inlet end of the fuel pump body, wherein the oil inlet assembly includes a pump cover 1, an impeller 2 and an impeller seat 3 arranged sequentially from outside to inside ;

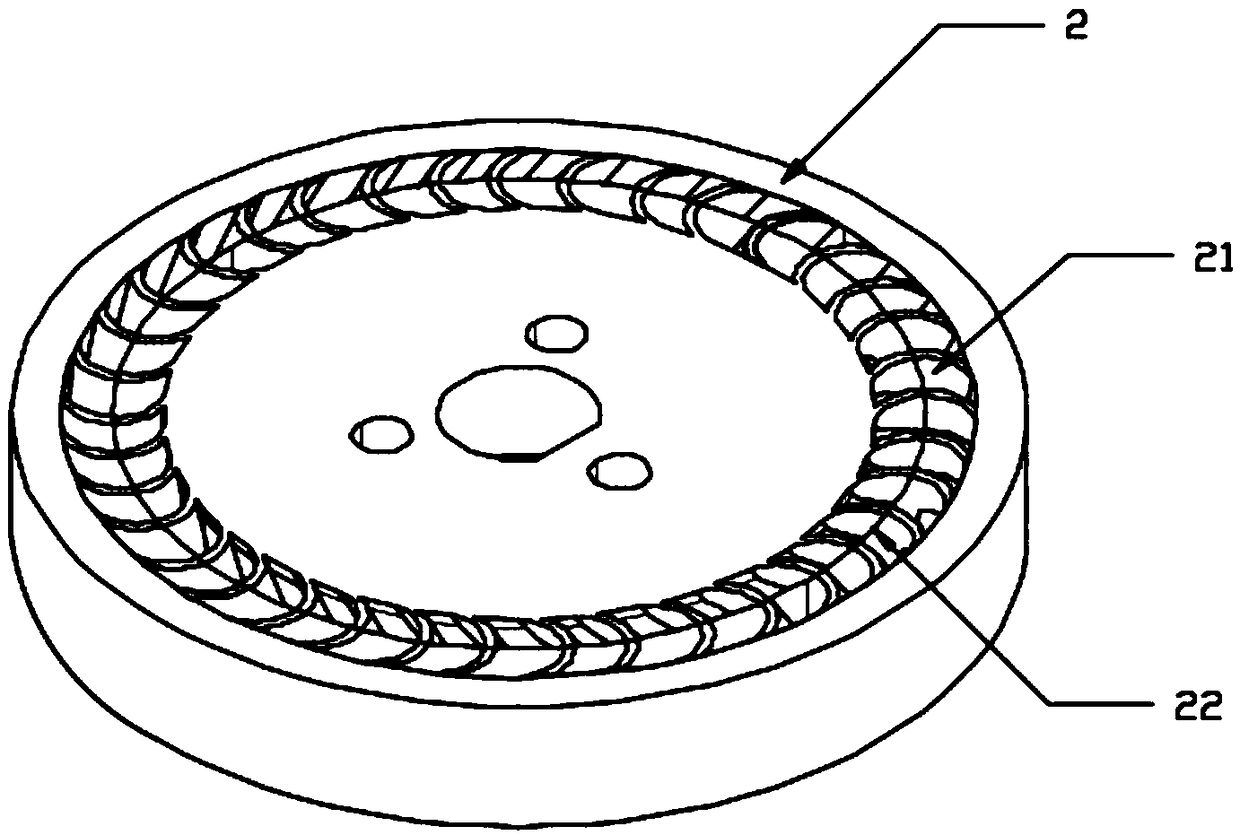

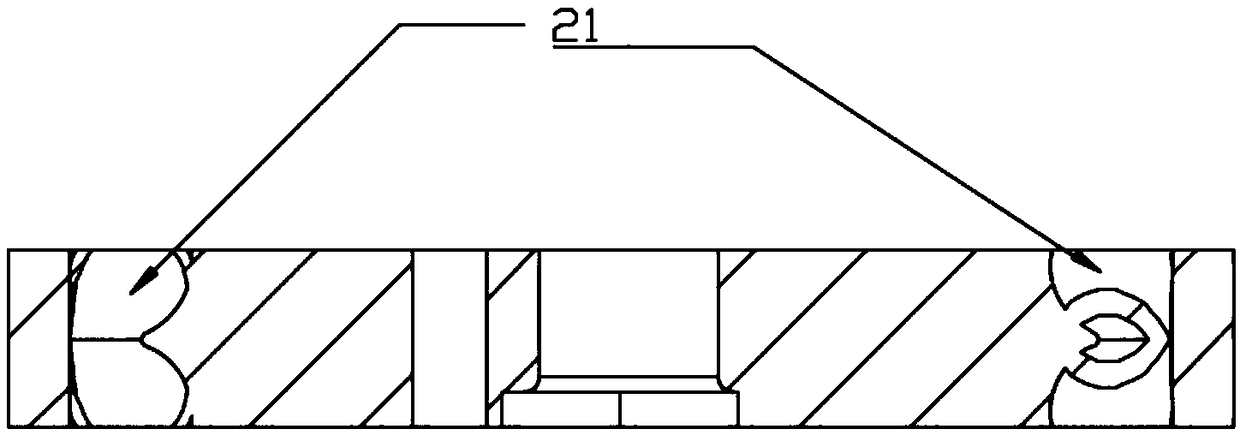

[0030] like figure 2 and image 3 As shown, the upper and lower end surfaces of the impeller 2 are oppositely provided with a plurality of arc-shaped blade groups 21, and the arc-shaped blade groups 21 include arc-shaped upper blades and lower blades, and the lower edge of the upper blade and the upper edge of the lower blade Fixed connection, adjacent arc-shaped blade groups 21 form arc-shaped passages in opposite directions up and down, the fluid flows from the pump cover 1 through the arc-shaped passages on the impeller 2, the interference is eased, and finally enters through the impeller seat in the fuel pump body.

[0031] like figure 2 As shown, adjacent arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com