Precision Drainage Liquid Measuring Cup

A technology for draining fluid and measuring cups, applied in liquid/fluid solid measurement, measuring device, measuring capacity, etc., can solve the hidden dangers of patient treatment, affect the judgment of patient recovery, increase the workload of nurses, etc., to reduce cross-infection, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

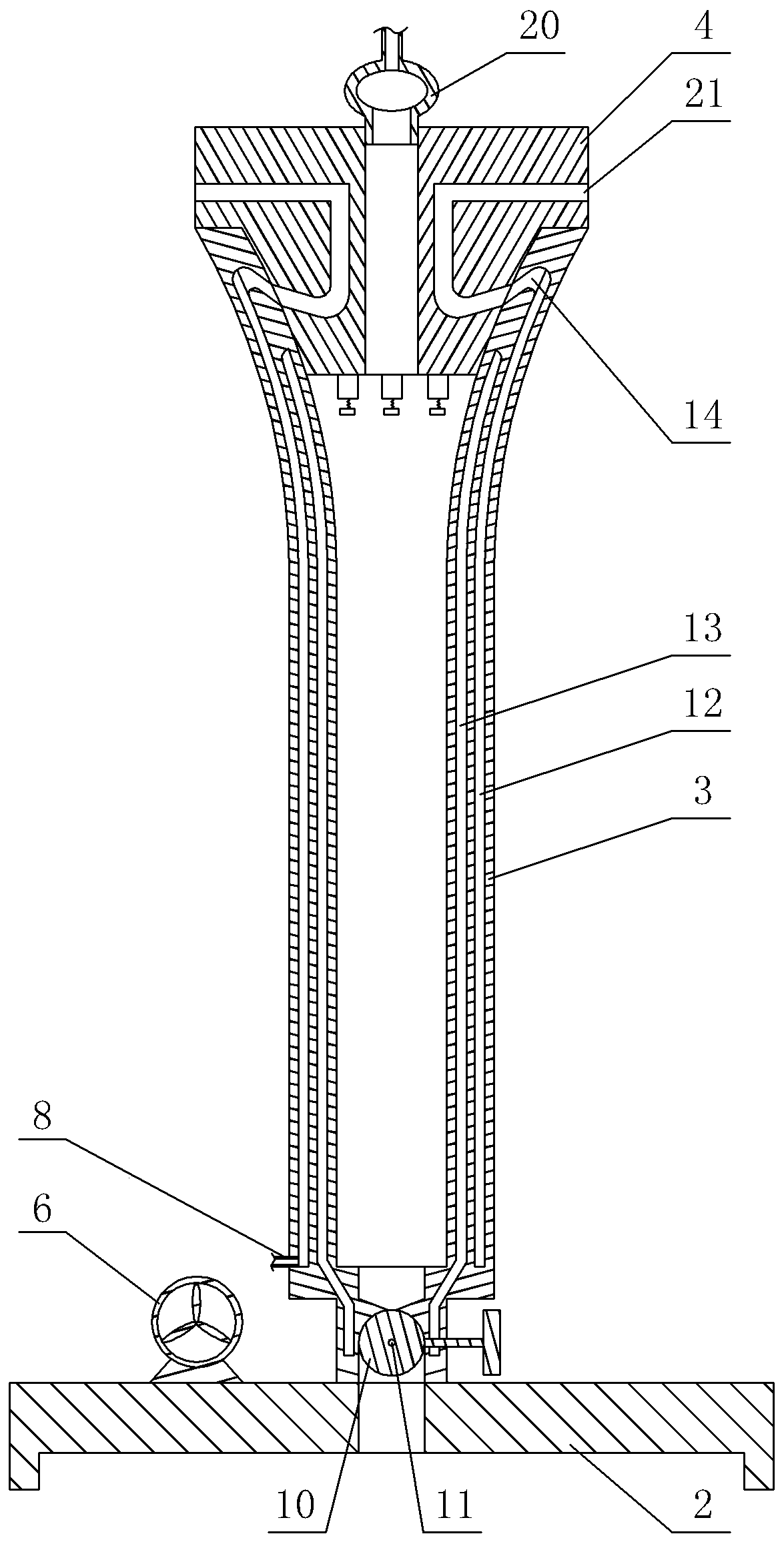

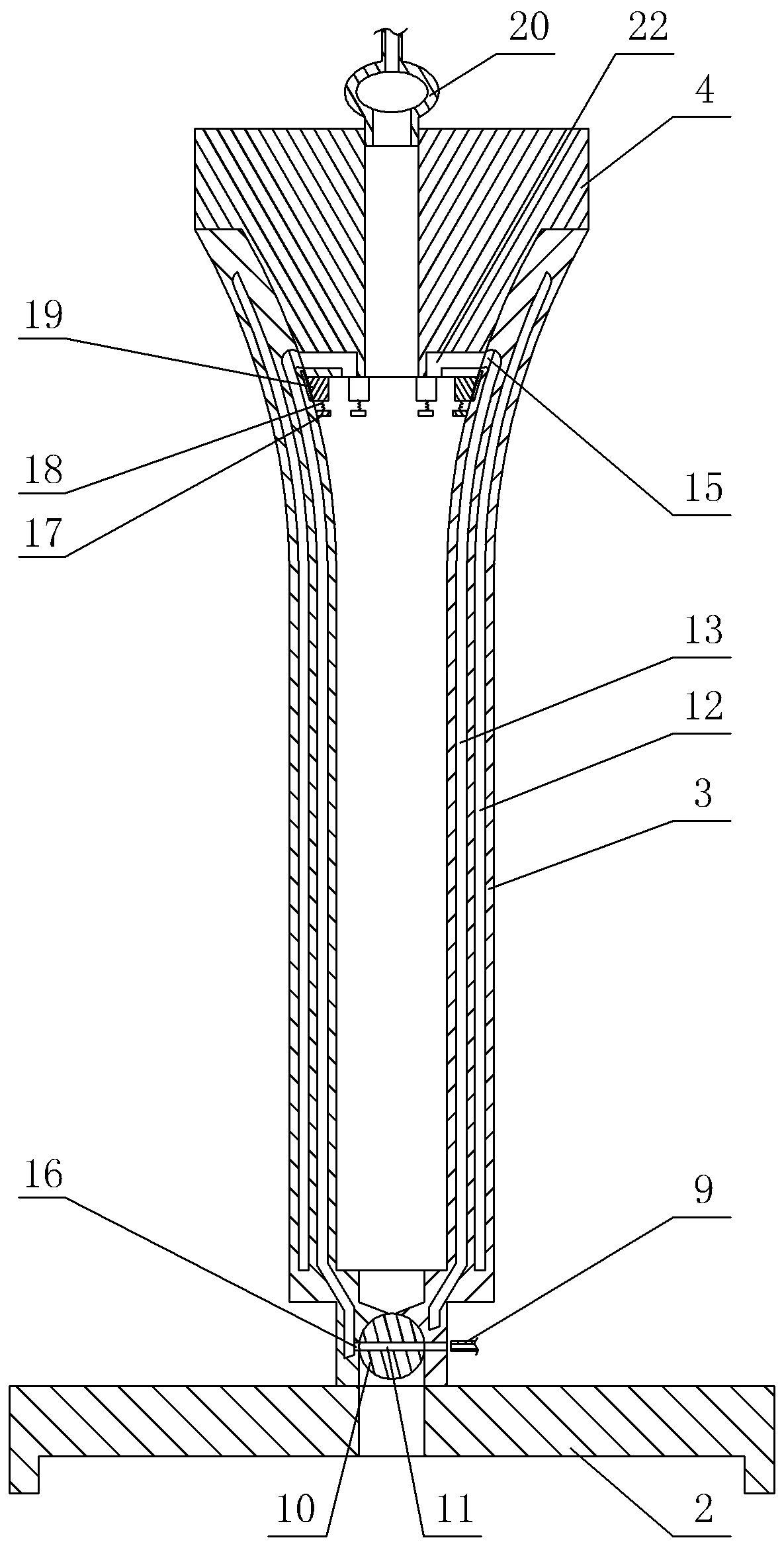

[0022] The reference signs in the accompanying drawings include: measuring cup body 1, cup cover 2, measuring cylinder 3, sealing plug 4, scale line 5, fan 6, cover 7, No. 1 hose 8, No. 2 hose 9, valve core 10. Leakage hole 11, outer cavity 12, inner cavity 13, air inlet hole 14, air outlet hole 15, negative pressure channel 16, support plate 17, spring 18, blocking plate 19, drainage ball 20, air outlet channel 21, Air intake channel 22.

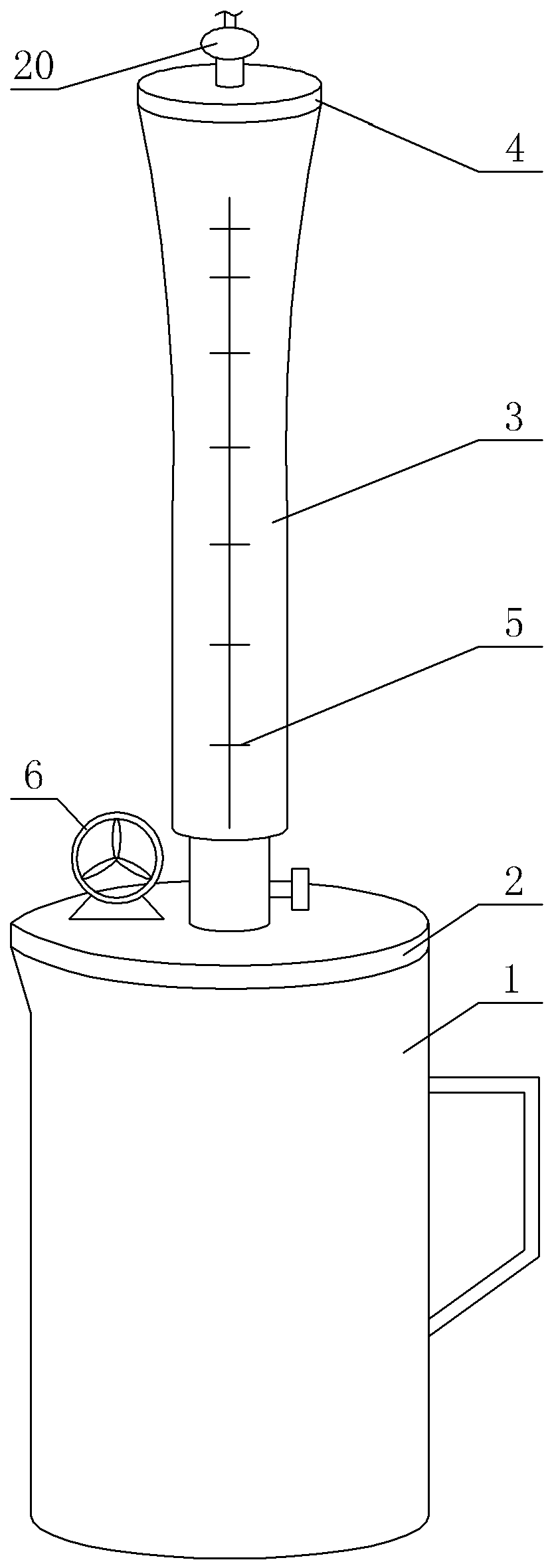

[0023] The embodiment is basically as attached Figure 1-5 Shown: as figure 1 The precision drainage liquid measuring cup shown includes a measuring cup body 1, a cup cover 2, a measuring cylinder 3 and a sealing plug 4 from bottom to top. The central position is integrally cast, and the outer cylinder wall of the measuring cylinder 3 is engraved with a blue scale line 5, the scale line 5 at the bottom represents 5ml, and the difference between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com