Repair method of pitch curve concave cusp design defect of N-blade non-circular gear

A repair method and non-circular gear technology, which is applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problem that the transmission accuracy of N-lobed non-circular gear pairs varies greatly and affects the transmission performance of N-lobed non-circular gear pairs 、No problems such as the effect of repairing the design defects of the concave point were raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

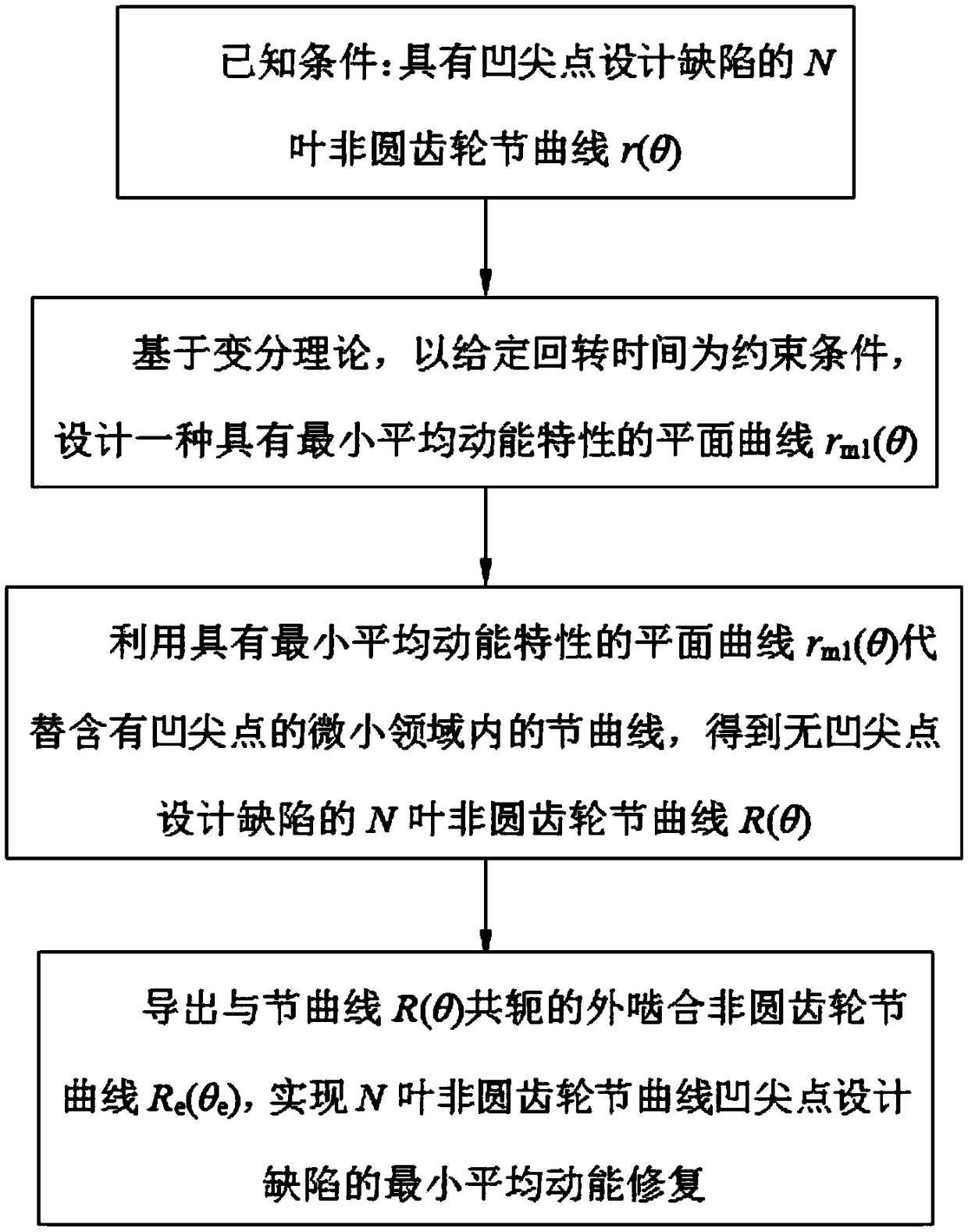

[0100] Such as figure 1 As shown, a method for repairing the design defect of the concave cusp point of the N-lobed non-circular gear pitch curve includes the following steps:

[0101] Step 1. Obtain the pitch curve r(θ) of the N-lobed non-circular gear satisfying the turnover constraint by rotating the pitch curve of the N-lobed non-circular gear with the design defect of the concave cusp point around the center of gyration:

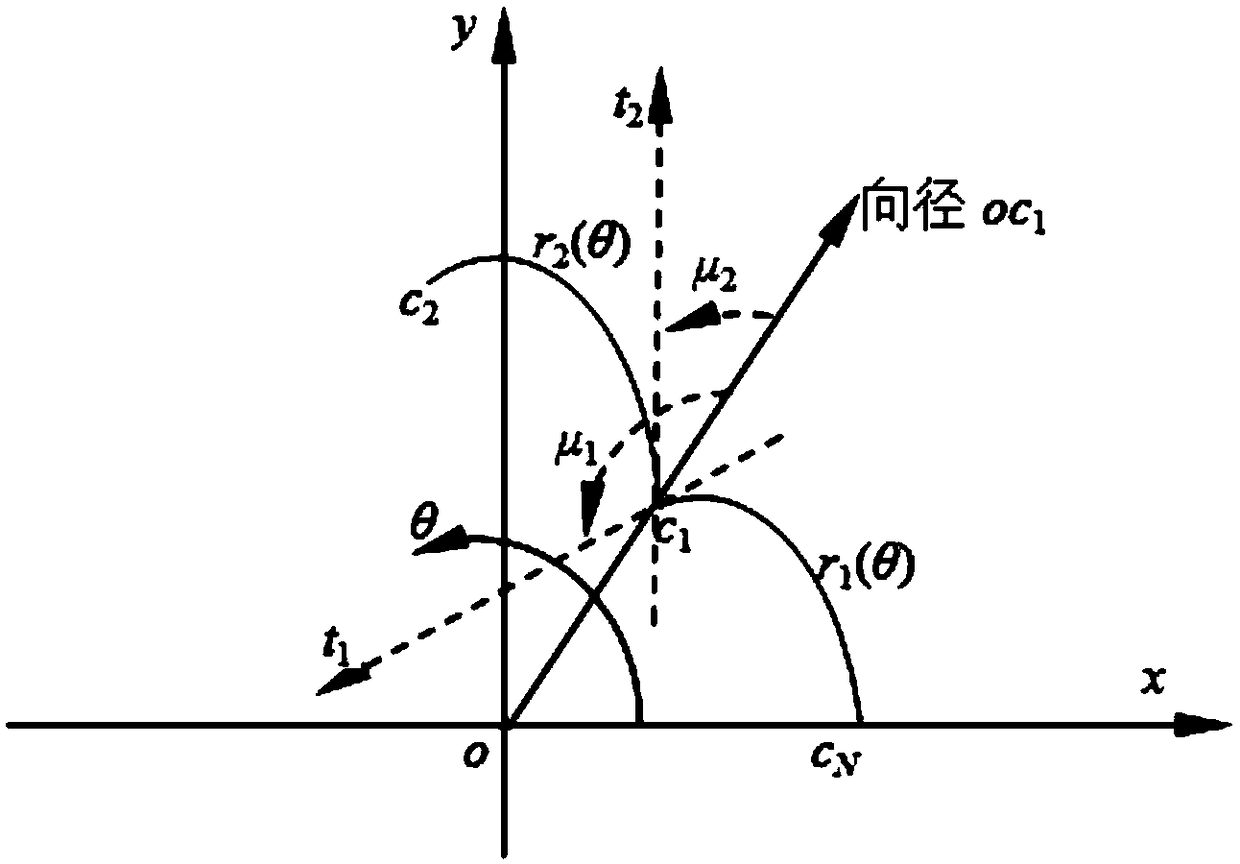

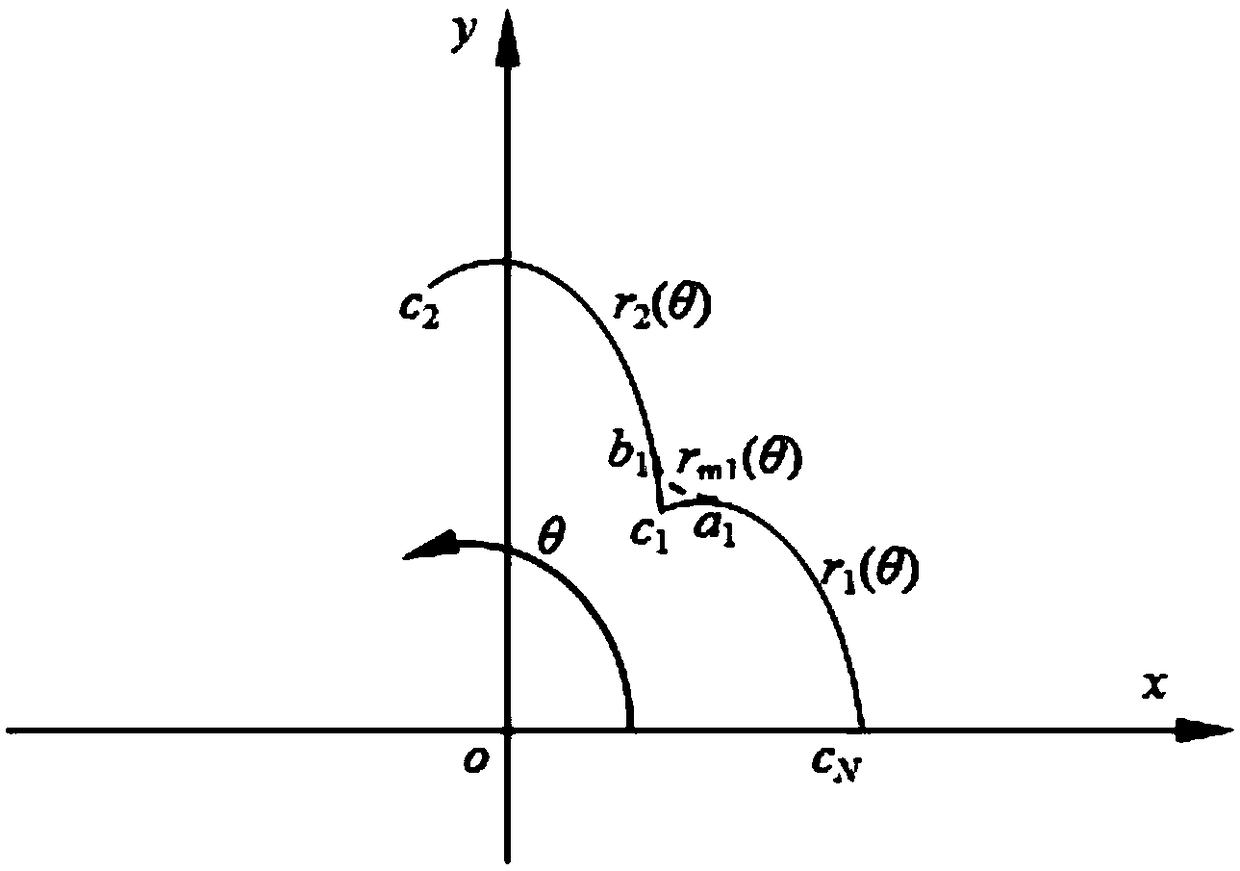

[0102] figure 2 The pitch curve of the N-lobe non-circular gear with the design defect of concave cusp. figure 2 In , the fixed coordinate system o-xy is rigidly connected to the center of gyration o, assuming an arbitrary curve r in the plane 1 (θ)(θ∈[0, 2π / N]) is the single-blade pitch curve in N-lobed non-circular gears, and the polar angle θ is measured counterclockwise with the positive direction of the x-axis, then by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com