Vision-based measuring method for cutting width of intelligent rice and wheat harvester

A wheat harvester and measurement method technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of non-target object interference, poor reliability, low precision, etc., and achieve the effect of avoiding potential safety hazards and real-time safe and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

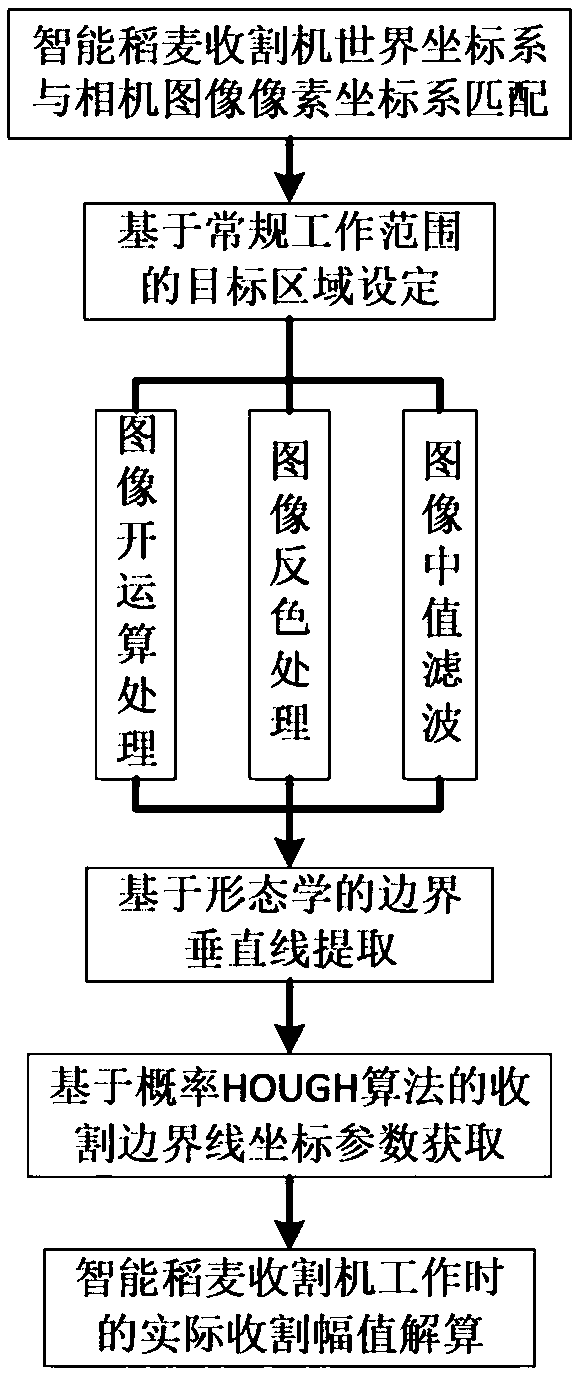

[0030] Such as figure 1 As shown, the present invention has designed a kind of vision-based intelligent rice and wheat harvester cutting width measuring method, and this method specifically comprises the following steps:

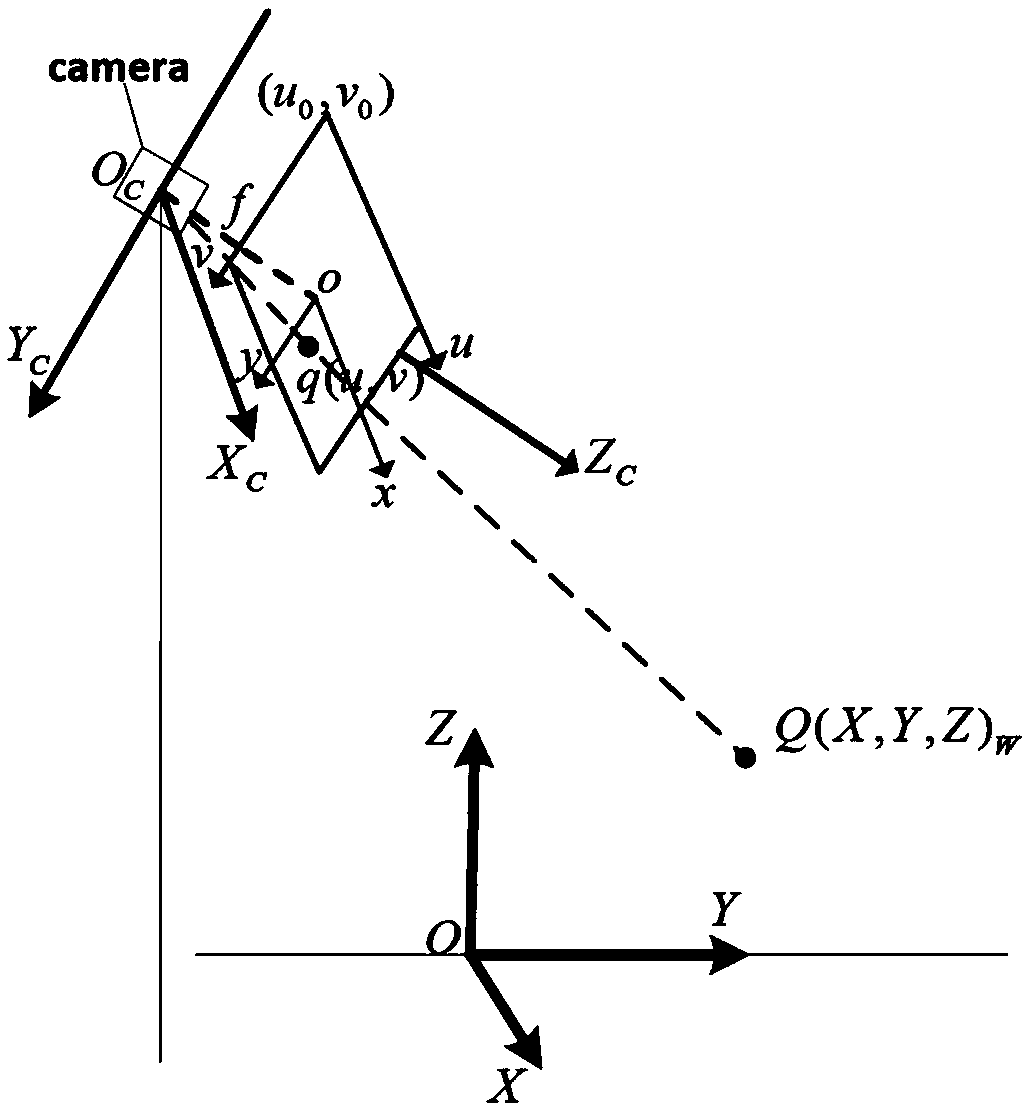

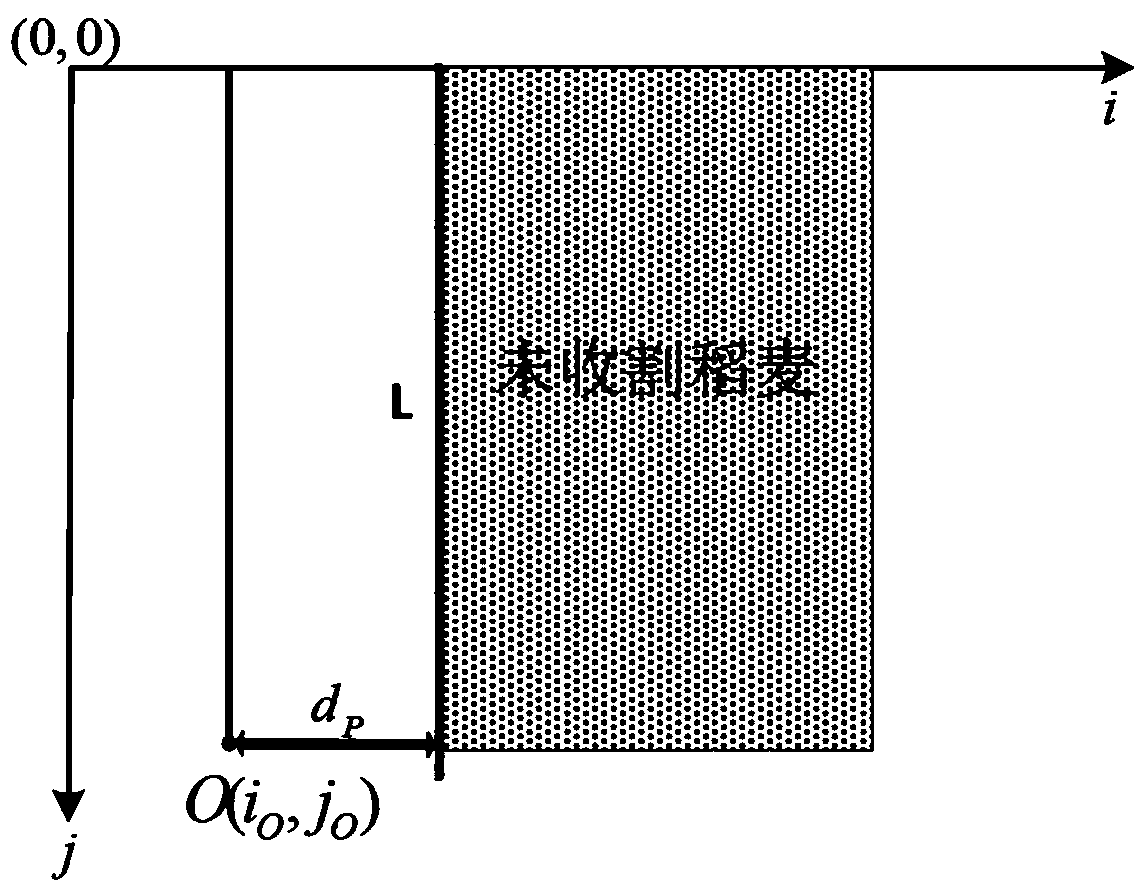

[0031] Step S1: According to the internal and external parameter matrix obtained by camera calibration, use the coordinate transformation formula to match the world coordinate system of the harvester with the camera image pixel plane coordinate system, and use the inverse perspective projection to match the camera image pixel plane coordinate system The original rice and wheat image is transformed into a top view, as follows:

[0032] First, the camera is installed on the top left side of the cab of the harvester, such as figure 2 As shown, set the camera coordinate system as (O C ,X C ,Y C ,Z C ), where the coordinate origin O C Locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com