A soft pseudo-carbonized fermented granule of corn licorice red snow tea, its preparation method and application

A technology of red snow tea and licorice, which is applied in the fields of application, tobacco, food science, etc., can solve the problems of cigarette aroma coordination, poor, and insignificant adsorption effect, etc., and achieve good application value, Improve the effect of increasing aroma and reducing coke, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Soft carbonization of corn licorice red snow tea

[0036] Put corn licorice red snow tea (the weight parts: 4 parts of corn, 3 parts of licorice, and 1 part of red snow tea) into the carbonization furnace, gradually raise the temperature of the furnace to about 80°C, keep it for 40 minutes, and wait for the corn licorice red snow After the tea is dried, rapidly raise the temperature to 120°C and keep it for 3 hours, turn off the heat source, and take out the soft carbonized sample of corn licorice red snow tea for later use (generally the raw material turns grayish brown, and the weight is 50-80% of that before soft carbonization).

[0037] 2. Cultivation of Bacillus subtilis Van3 (B.subtilisVan3)

[0038] A. Test tube slant culture

[0039]A Luria-Bertani (LB) medium was used, and the formula was: 10 g of peptone, 10 g of sodium chloride, 5 g of yeast extract, 20 g of agar, and distilled water to a volume of 1000 ml. Sterilize at 121°C for 25 minutes and place on ...

Embodiment 2

[0047] 1. Soft carbonization of corn licorice red snow tea

[0048] Put corn licorice red snow tea (parts by weight: 3 parts of corn, 2 parts of licorice, and 1 part of red snow tea) into the carbonization furnace, gradually raise the furnace temperature to 80°C, keep it for 30 minutes, and wait for the corn licorice red snow tea After drying, the temperature was raised rapidly to 140°C and kept for 2.5 hours, the heat source was turned off, and the pseudo-carbonized sample of corn licorice red snow tea was taken out for later use.

[0049] 2. The culture method of Bacillus subtilis Van3 is the same as that in Example 1.

[0050] 3. Fermentation of corn licorice red snow tea kneading and imitating carbonization

[0051] Weigh 500g of soft and carbonized corn licorice red snow tea to balance the moisture to 12wt%, spray 100mL of the Bacillus subtilis Van3 obtained above, and then put it in a constant temperature and humidity box at 22°C and a relative humidity of 60% for ferme...

Embodiment 3

[0054] Example 3: Corn licorice red snow tea soft pseudo-carbonized fermented particles are applied to cigarette filter rods

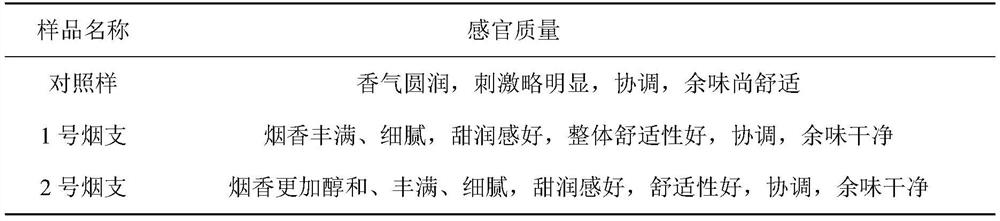

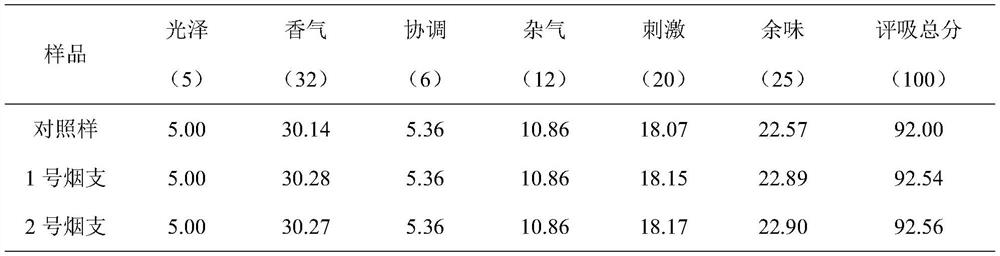

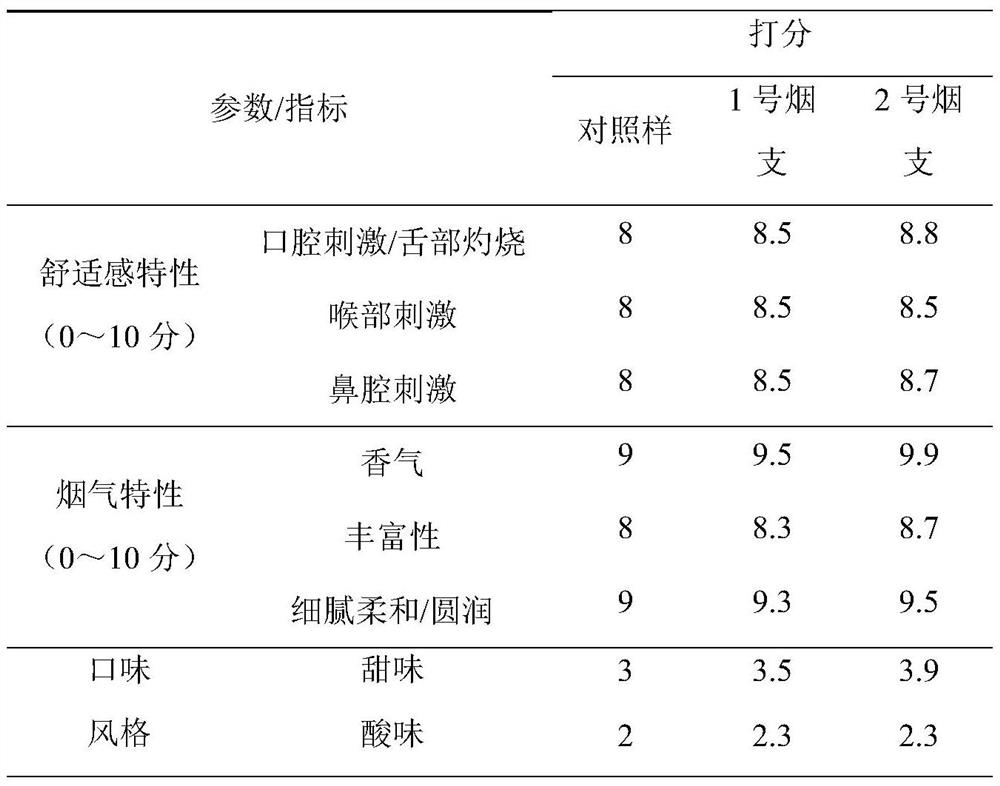

[0055] Apply the corn licorice red snow tea soft pseudo-carbonized fermentation granules obtained in Example 1 to composite cigarette filter sticks, add 1.5 mg of granular material per millimeter of standard cigarette filter sticks, and prepare experimental cigarettes, named No. 1 cigarette Cigarette sticks; with the cigarettes without the above-mentioned particles as the control sample, the moisture content of the cigarette samples was adjusted to 12wt% according to the national standard "GB / T16447-1996 Atmospheric Environment for the Regulation and Testing of Tobacco and Tobacco Products", and the smoking expert group was evaluated according to "GB5606 .4~1996 Cigarette Sensory Technical Requirements" to carry out sensory evaluation of cigarettes and detection of harmful components in smoke. See Table 1 for the evaluation results; see Table 2 and Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com