A Flotation Separation Method of Mixed Concentrate Based on Enhanced Suppression of Lead Sulfide

A technology of mixing concentrates and separation methods, applied in flotation, solid separation, etc., can solve the problem of failure to completely realize the effective separation of copper, lead or lead and zinc, difficulty in changing the surface floatability difference of copper and lead minerals, and the surface of lead sulfide Weak inhibitory effect and other problems, to achieve the effect of low cost, strong pertinence, and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

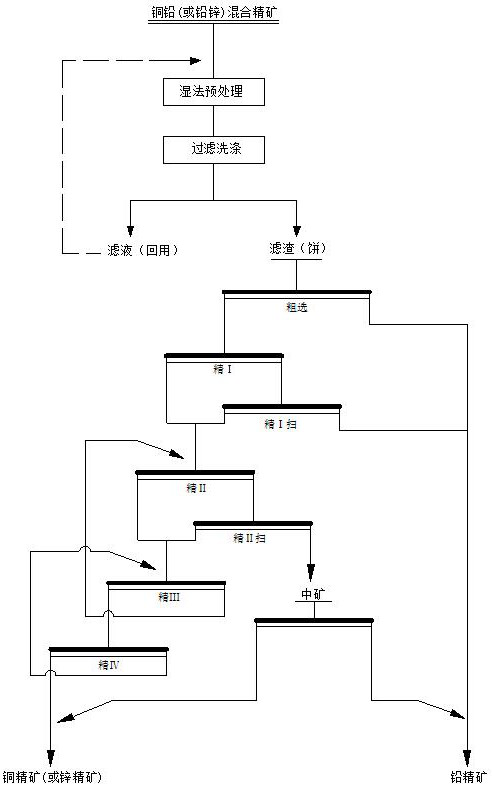

[0026] Embodiment 1: as figure 1 As shown, a mixed concentrate flotation separation method based on enhanced inhibition of lead sulfide, the mixed concentrate is a fine-grained copper-lead sulfide mixed concentrate, in this mixed concentrate, the particle size is less than 400 mesh by mass, accounting for 95%, of which Containing Cu13.92wt%, Pb15.35wt%, the main copper mineral is copper sulfide (40.03wt%), the main lead mineral is lead sulfide (17.16wt%), and the remaining gangue minerals are small, mainly quartz, calcite and kaolinite Mainly, the specific steps are as follows:

[0027] (1) Wet pretreatment of mixed concentrate: place the copper-lead sulfide mixed concentrate in a stirring tank, add sulfuric acid solution with a mass concentration of 20% and manganese dioxide to the copper-lead sulfide mixed concentrate to adjust to The pulp concentration is 30%, wherein the mass ratio of the added manganese dioxide mass to the mixed concentrate is 1:100g, the pulp is heated ...

Embodiment 2

[0032] Embodiment 2: A kind of mixed concentrate flotation separation method based on strengthening and suppressing lead sulfide, the mixed concentrate is a fine-grained copper-lead sulfide mixed concentrate, and in this mixed concentrate, the particle size is less than 400 mesh by mass and accounts for 90%. It contains Cu14.56wt%, Pb16.37wt%, the main copper mineral is copper sulfide (41.70wt%), the lead mineral is lead sulfide (18.05wt%), and the remaining gangue minerals are a small amount of quartz, kaolinite and serpentine Mainly. Specific steps are as follows:

[0033](1) Wet pretreatment of mixed concentrate: place the copper-lead sulfide mixed concentrate in a stirring tank, add sulfuric acid solution and ammonium persulfate with a mass concentration of 25% to the copper-lead sulfide mixed concentrate, adjust Until the pulp concentration is 35%, the mass ratio of the added ammonium persulfate to the mixed concentrate is 2g:100g, the pulp is heated to 85°C, the stirrin...

Embodiment 3

[0039] Embodiment 3: A kind of mixed concentrate flotation separation method based on strengthening and suppressing lead sulfide, the mixed concentrate is a fine-grained copper-lead-zinc sulfide mixed concentrate, and in this mixed concentrate, the particle size is less than 400 mesh by mass and accounts for 85% , which contains Cu16.24wt%, Pb25.71wt%, Zn7.51wt%, the main copper mineral is copper sulfide (45.94wt%), the lead mineral is lead sulfide (29.02 wt%), the main zinc mineral is zinc sulfide (11.05 wt%) and the rest of the gangue minerals are mainly a small amount of quartz and carbonate. Specific steps are as follows:

[0040] (1) Wet pretreatment of mixed concentrate: place the copper-lead-zinc sulfide mixed concentrate in a stirring tank, add sulfuric acid solution with a mass concentration of 30% to the copper-lead-zinc sulfidized mixed concentrate, and adjust to a slurry The concentration is 35%, the pulp is heated to 95°C, the stirring speed is 500r / min, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com