A Sound Field Separation Method Using Sparse Measurements

A separation method and sound field technology, which are applied in the measurement of ultrasonic/sonic/infrasonic waves, measurement devices, instruments, etc., can solve the problems of resolution limitation, affecting the scope of use, and high measurement cost, and achieve the effect of high separation accuracy and spatial resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

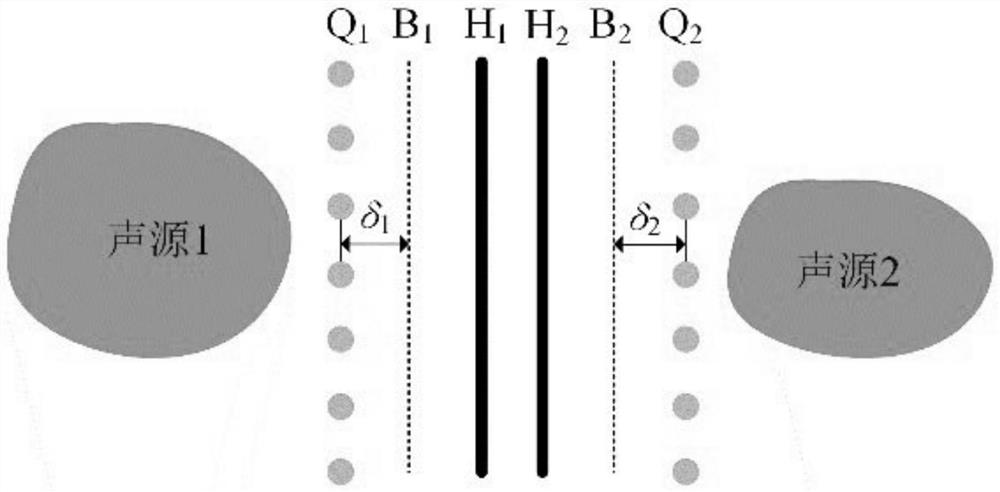

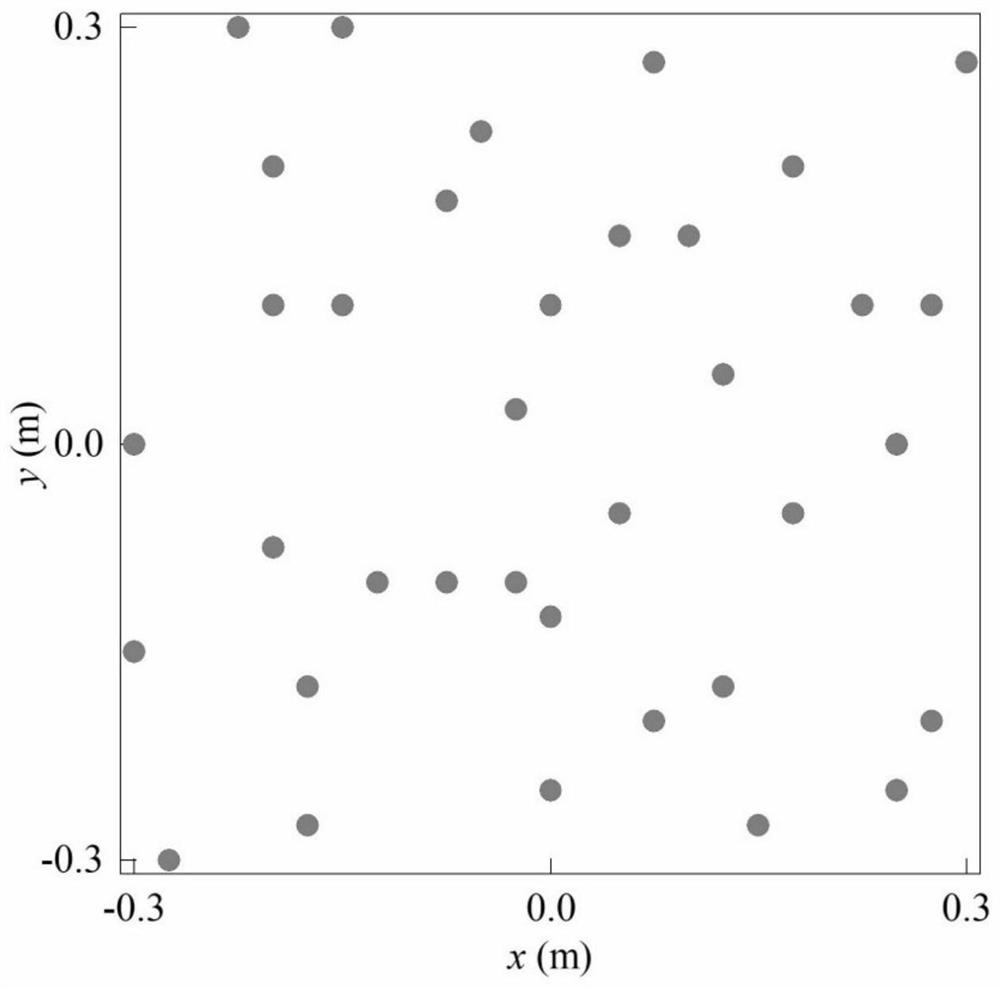

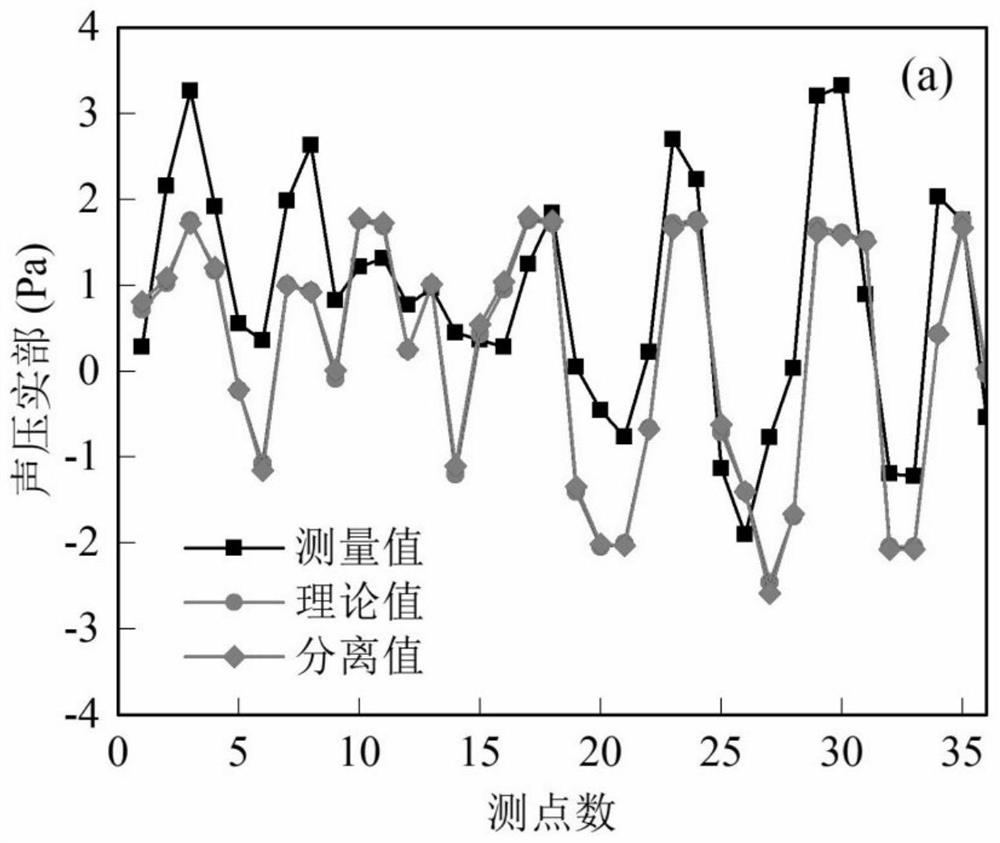

[0040] Example: two pulsating spheres with a radius of 0.01m are used as sound sources, and their surface vibration velocity is 1m / s, and the sound source located at (0.25,0.25,-0.4)m is sound source 1, located at (0.25, The sound source at 0.25, 0.4) m is sound source 2. The measuring surface is located at z H1 = -0.025m and z H2 =0.025m, 36 measuring points are arranged on each measuring surface, the distribution of measuring points is as follows figure 2 As shown, the distance between the two equivalent sound source surfaces and the virtual boundary surface is 0.075m. Gaussian white noise is added to the two measurement surfaces and the signal-to-noise ratio is 30dB. By superimposing the sound pressure signals of sound source 1 and sound source 2 with the point sound source to form a fitted sound field, the sparseness of the sound pressure vector of the fitted sound field is obtained. According to the sound pressure signal and the sparse basis, the sparse solution of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com