Sharpness detection device for steel saw production

A detection device and a sharpness technology, which are applied in the field of sharpness detection devices for hacksaw production, can solve the problems of easy soreness in hands, holding down materials, and easy impact on the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

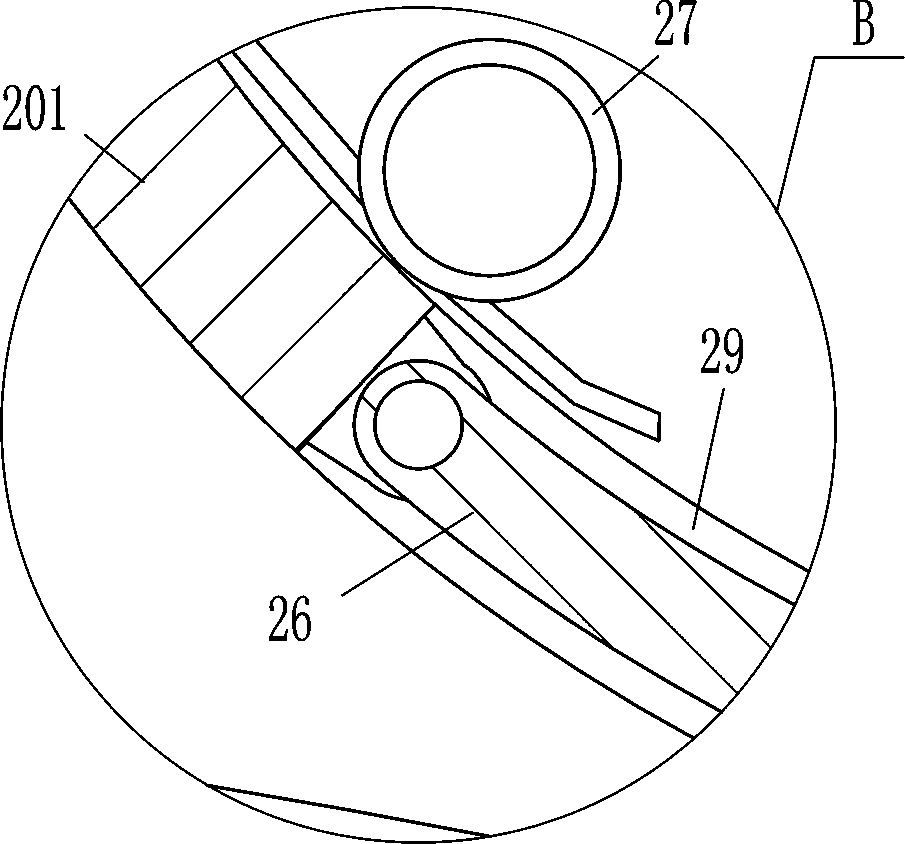

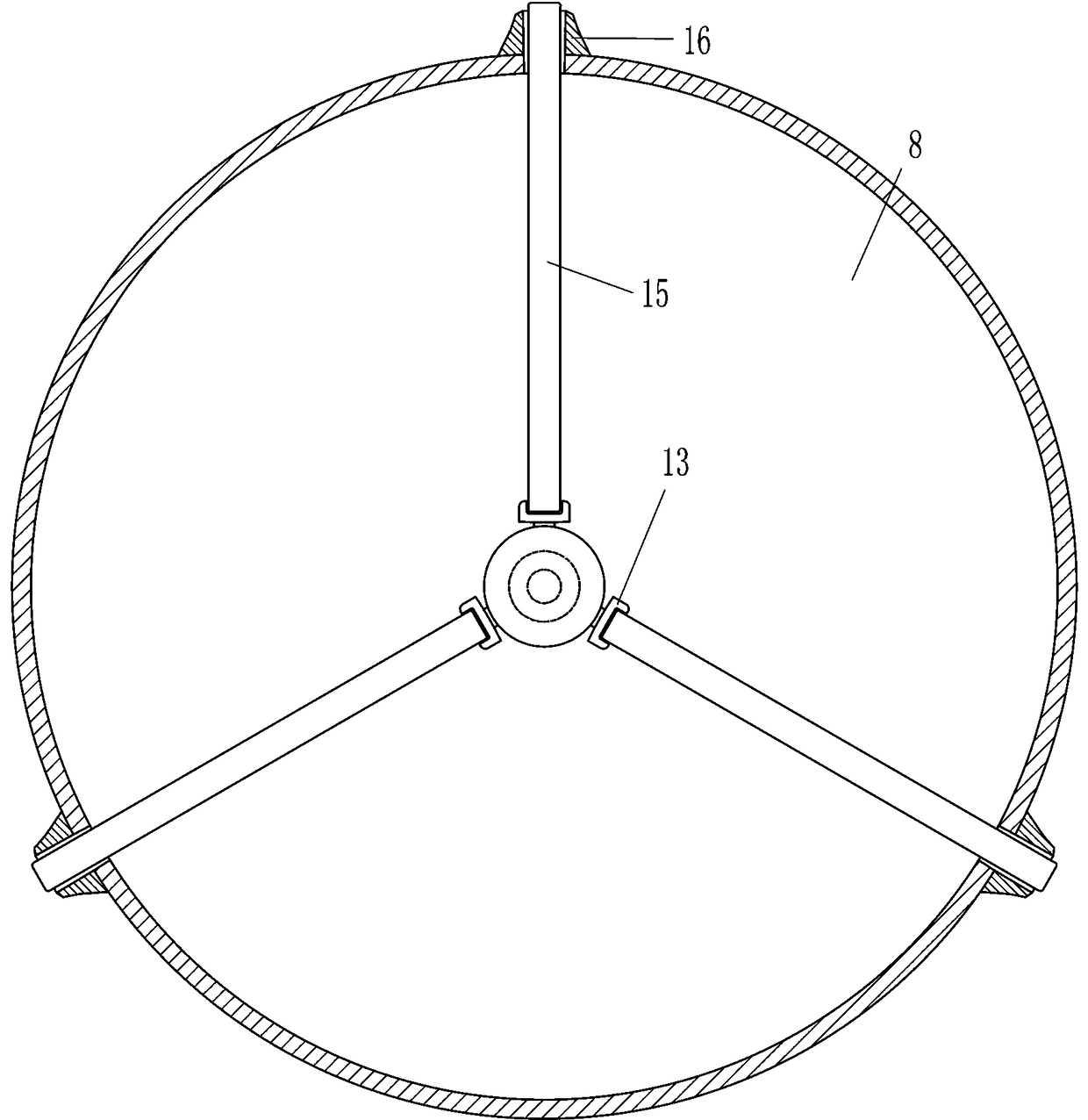

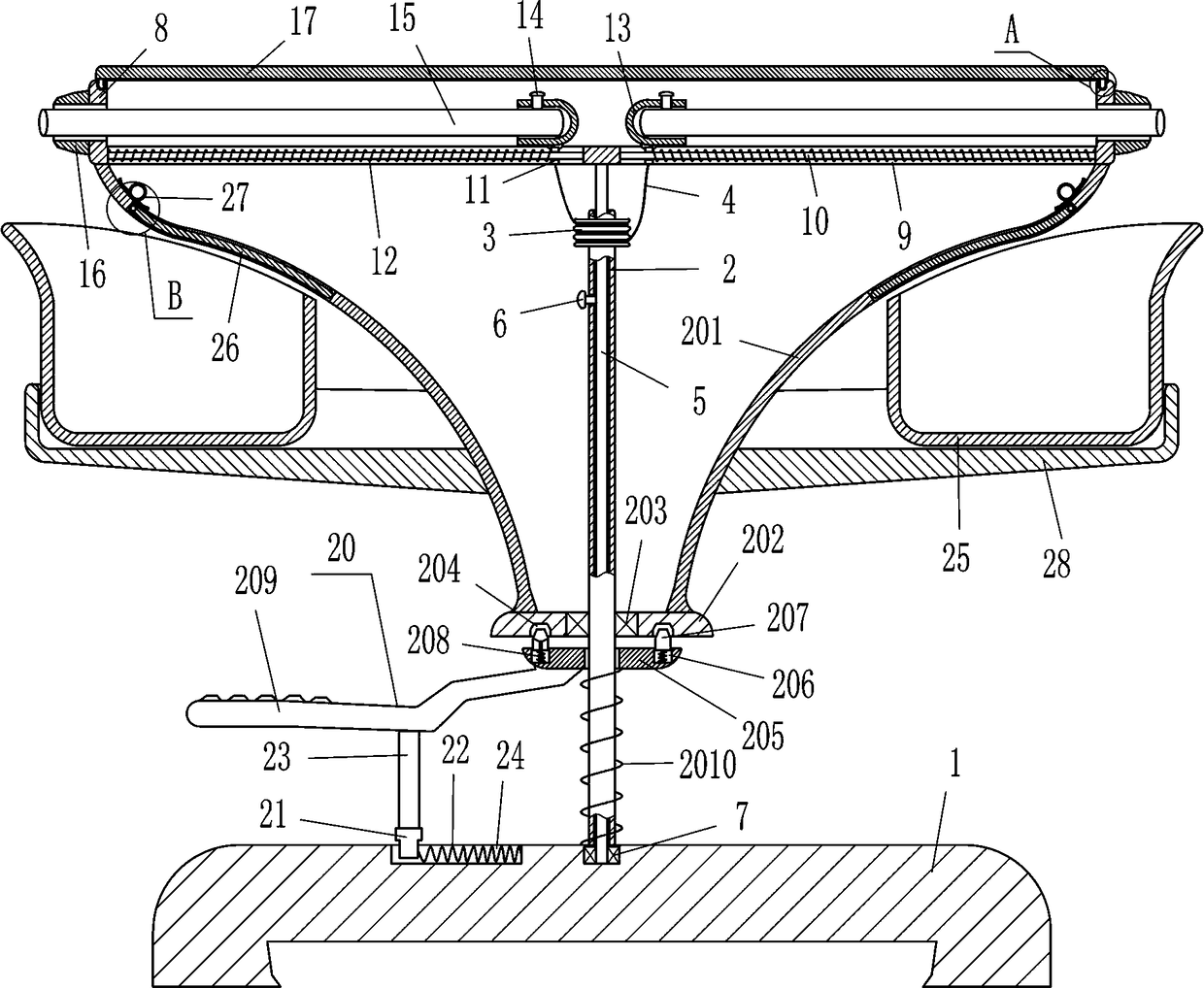

[0020] A sharpness detection device for hacksaw production, such as Figure 1-4 As shown, it includes a base 1, a sleeve 2, a three-slot reel 3, a pull wire 4, a rotating shaft 5, a first fastening bolt 6, a first bearing seat 7, a circular frame 8, a guide rod 10, and a sliding sleeve 11 1. The first spring 12, the ferrule 13, the second fastening bolt 14, the guide sleeve 16, the cover plate 17 and the insertion rod 18, the casing 2 is fixedly connected in the middle of the top of the base 1, and the upper part of the outer surface of the casing 2 is fixedly connected with three slots Winding wheel 3, three stay wires 4 are wound on the three-slot winding wheel 3, a rotating shaft 5 is arranged in the casing 2, and a first fastening bolt 6 is arranged on the upper left side of the casing 2, and the first fastening bolt 6 is connected with the rotating shaft 5 contacts, the top of the rotating shaft 5 is affixed with a circular frame 8, and the outer surface of the circular f...

Embodiment 2

[0022] A sharpness detection device for hacksaw production, such as Figure 1-4As shown, it includes a base 1, a sleeve 2, a three-slot reel 3, a pull wire 4, a rotating shaft 5, a first fastening bolt 6, a first bearing seat 7, a circular frame 8, a guide rod 10, and a sliding sleeve 11 1. The first spring 12, the ferrule 13, the second fastening bolt 14, the guide sleeve 16, the cover plate 17 and the insertion rod 18, the casing 2 is fixedly connected in the middle of the top of the base 1, and the upper part of the outer surface of the casing 2 is fixedly connected with three slots Winding wheel 3, three stay wires 4 are wound on the three-slot winding wheel 3, a rotating shaft 5 is arranged in the casing 2, and a first fastening bolt 6 is arranged on the upper left side of the casing 2, and the first fastening bolt 6 is connected with the rotating shaft 5 contacts, the top of the rotating shaft 5 is affixed with a circular frame 8, and the outer surface of the circular fr...

Embodiment 3

[0025] A sharpness detection device for hacksaw production, such as Figure 1-4 As shown, it includes a base 1, a sleeve 2, a three-slot reel 3, a pull wire 4, a rotating shaft 5, a first fastening bolt 6, a first bearing seat 7, a circular frame 8, a guide rod 10, and a sliding sleeve 11 1. The first spring 12, the ferrule 13, the second fastening bolt 14, the guide sleeve 16, the cover plate 17 and the insertion rod 18, the casing 2 is fixedly connected in the middle of the top of the base 1, and the upper part of the outer surface of the casing 2 is fixedly connected with three slots Winding wheel 3, three stay wires 4 are wound on the three-slot winding wheel 3, a rotating shaft 5 is arranged in the casing 2, and a first fastening bolt 6 is arranged on the upper left side of the casing 2, and the first fastening bolt 6 is connected with the rotating shaft 5 contacts, the top of the rotating shaft 5 is affixed with a circular frame 8, and the outer surface of the circular f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com